The most significant risk to our project currently is the finishing and functionality of the wireless transmitter boards due to their strange behavior, which we have explained extensively in person as well as in our individual status reports. We are managing this risk by trying multiple solutions, including buying smaller coil transmitter boards that come from a different set of testing boards than the set we bought along with reaching out for help to the teaching staff. Our contingency plan in case the wireless charging completely does not work is to have strips of metal as the charger and put contact pads on the bottom of our keys instead.

Another risk is connecting more than 7 keys to connect to one BLE receiver. The new boards that we bought since we thought could raise the limit on the number of BLE connections (which is limited by the allotted memory to each BLE thread), but even after going through the process of raising the limit in the system constants, only 2 BLE connections would ever actually go through. This led us to try working on increasing the limit on our original main microcontroller, but the processes found online are from 5-6 years ago and no longer work. More information can be found in Ben’s status report. The backup plan in case we cannot increase this limit is to use multiple BLE receivers (3 max).

No changes were made to the existing design of the system.

The schedule is the same except the wireless charging task has been extended and we are working on that and other tasks concurrently.

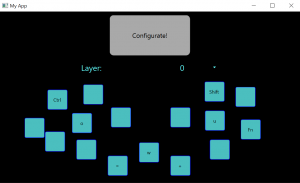

Here are some pictures of our updated app and app output files:

Here is our newest iterations of the 3D printed housing: