What are the most significant risks that could jeopardize the success of the project? How are these risks being managed? What contingency plans are ready?

The biggest risk right now is making sure the whole system works. There were a couple of bugs in the HID driver that require fixing. For example, the compute module was successfully able to classify the input sensor data and attempted to dispatch it to the computer, but sometimes the host computer was not able to receive it. We also experimented with debouncing times so that random gestures aren’t picked up but the action isn’t too slow.

Were any changes made to the existing design of the system (requirements, block diagram, system spec, etc)? Why was this change necessary, what costs does the change incur, and how will these costs be mitigated going forward?

None since last week.

Provide an updated schedule if changes have occurred

No changes.

Team work adjustments

No teamwork adjustments have been made. We are currently on track to accomplish our tasks and are currently all just working on them.

List all unit tests and overall system test carried out for experimentation of the system. List any findings and design changes made from your analysis of test results and other data obtained from the experimentation.

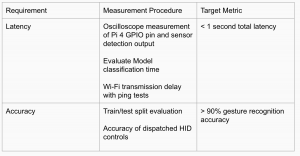

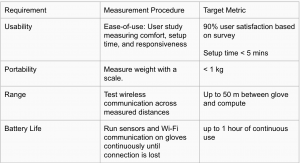

- Latency tests – averaged over 20 trials. The finding we found is that using a time-series-based approach is pretty speedy compared to neural networks, which was stated in the presentation.

| Measurement | Actual Value |

| Oscilloscope measurement of Pi 4 GPIO pin and sensor detection output

(overall measurement) |

~ 112ms |

| Sensor data collection | ~ 100ms |

| Model classification time | ~ 5ms |

| Wi-Fi transmission delay with ping tests | ~ 5ms |

| Dispatch time | TBD |

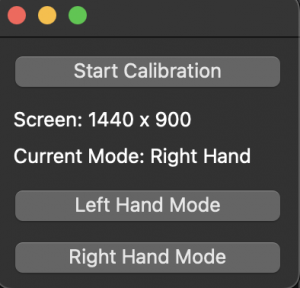

2. User experience tests. The finding we found is that our initial goals were overestimates as we were able to significantly exceed the target metrics we had, with the exception of the range. This is because we felt like for the best user experience, the configuration should be as hands-free as possible, which is why we switched the communication protocol from local wifi to using the Raspberry Pi as a hotspot. That way, we would not need to reconfigure both the glove and Pi when the user uses the glove in a different location. Even though this came with a trade-off of lesser range, we decided it was alright considering that it still worked at least 10 meters away, which is far enough in a classroom setting.

| Requirement | Measurement Procedure | Target Metric | Actual Value |

| Usability | Ease-of-use: User study measuring comfort, setup time, and responsiveness | 90% user satisfaction based on survey

Setup time < 5 mins |

~4 minutes |

| Portability | Measure weight with a scale. | < 500 g | 57g + 34g battery = 91g |

| Range | Test wireless communication across measured distances | Up to 50 m between glove and compute | 10 m |

| Battery Life | Run glove module with all sensors and communication running and measure total power consumption | up to 1 hour of continuous use | ~40 hours |

3. Accuracy tests – We tested the zoom-in and out gestures, however, the zoom-in wasn’t as accurate as we had hoped. We found out that the sensor of the index finger wasn’t that responsive to flex, which is particularly important for our zoom-in gesture. Xuan will replace the sensor in hopes that the algorithm will achieve higher accuracy.

| Train/test split evaluation

Accuracy of dispatched HID controls |

> 90% gesture recognition accuracy | 95% for rotation/pan

Zoom in – 65% Zoom out – 90% Enable-disable – TBD Dispatch accuracy TBD |