As the semester is coming to a close, we are working on the poster and the final video. In order to demo, I have a couple of minor bugs I need to work out in the CV; afterwards, we will be ready to finish up our filming. I have also been recording my part in the video, which explains the computer vision part of the stack. There’s not much else to add, other than that we are working on wrapping the semester up!

Brandon Hung’s Status Report

This week was quite busy for me, but I still tried to make as much time as possible to work on a new approach to the CV. My first attempt of CV was tuning a color segmentation algorithm. However, this simple was not working because variations in lighting are devastating to color segmentation algorithms. If we continued using the same approach, I do not think it would be possible to meet the requirements. After thinking about the problem, I’ve come up with a preliminary solution idea I’ve spent most of the day implementing. The idea is to use the white checkers on the chips as a marker. I plan on aggregating the white markings to group them together. This is done by searching the surrounding image area for more chips. Then, draw a rectangle around the grouped markings to get a bounding box. This allows me to use the least squares approximation to fit a line between the bases of the rectangles; once that is done, I will be able to rotate the image so the stacks are roughly horizontally matched. From that point, I can rotate the rectangles to get the true height of the stacks. This algorithm is a lot more involved than the previous one, so I am working on getting it right. I have several bugs with aggregation, which I hope to solve before tomorrow.

Brandon’s Status Report: 4/3

I’ve been working on the CV this week. It’s proven a bit more difficult than I’d imagined because of lighting; color doesn’t stay consistent throughout different lighting schemes. So far, I have been looking into pre-processing operations to manage this issue better and looking at different algorithms for alternative ways to detect chips.

Here is an example of poor lighting causing the stacks to be slightly off. While it is still possible to see the stack, the colors behind it cause a bit of confusion. The color is better in brighter conditions, leading me to wonder if we should solve this by providing better lighting or by providing a better algorithm. I will continue to work on a fix, but I may have to switch schemes later and rely on another method.

Brandon’s Status Report: 3/27

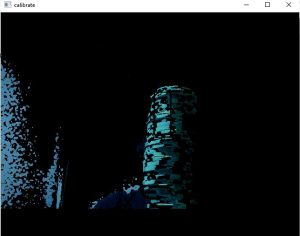

Due to midterms and several large homeworks, I was unable to get as much done as I wanted this week. That being said, I have completed the calibration routine and am working on the color masking for the computer vision. An example of the calibration can be seen in the image below:

where you can click on the picture and it will automatically calibrate to the RGB threshold values to +/- a delta of the pixel you have highlighted. In addition, I have finished the CAD, so we should be getting ready to 3D print soon!

Brandon’s Status Report 3/13

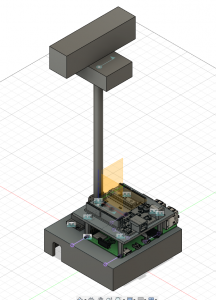

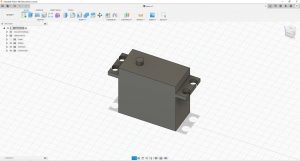

This week, I did not get as much done on the vision side. This was mainly due to slow lead times on item delivery. However, I did manage to create several models for the design of our turntable, layout, and visualization for the report. Once I receive the Pi next week, I will begin experimenting with CV on it.

Servo Model

Table Isometric

Table Top View

Brandon’s Status Report for 3/6/21

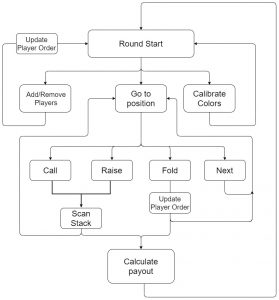

This week has mostly been spent ordering parts and working on the design review. I diagrammed a couple flow chart and helped to create the game state representation. I also drew out a basic schematic of the table layout. I also ordered a camera, and my teammate ordered me a Raspberry Pi. I hope to work next week on the physical hardware and begin to detect and measure stacks.

Brandon’s Status Report: 02/27/21

This week’s progress has been slightly slower than I had expected. I spent some time reacquainting myself with OpenCV and looking at hardware elements we might need for the project. Two examples of good cameras I have found are:

Both meet the technical requirements we placed for the cameras except maybe for power. However, since USB 2.0 is power limited by 0.5 A max, then the theoretical upper bound on the webcam power usage is 2.5 W, which is perfectly acceptable.

Next week, I hope our team can get together and work on the design for representing game state.

Brandon’s Status Report: 02/19/21

So far, I have mostly been looking for parts and ideas on how to design the system this week. Since we shifted focus away from the original idea, which used RFID, I have been more focused on looking at cameras and motors, along with power supplies, for the device. While I expect changes to happen as we go along, given how our last idea shifted focus away from reading cards to more of a ease-of-use service device, I think these parts will stay pretty constant to any iteration of this project from here on.