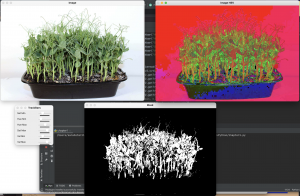

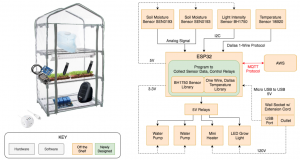

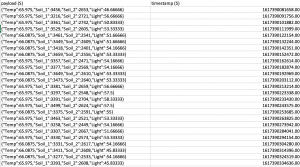

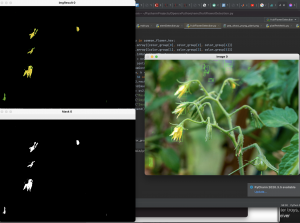

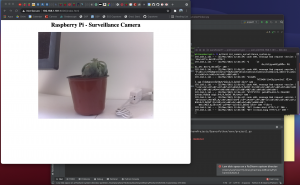

This week, while we worked on our individual components, we also began to connect those components together. Sarah was able to embed the video to a simple HTML site running on local host, so we are expecting the transition from this to the actual website will be smooth. Hiroko and Kanon worked on the connection of the ESP32 to AWS, and were successfully able to send and receive data. All of us also planted some pea shoots for testing. Sarah was able to test her growth classifier implemented by detecting the sprouting of the pea shoots. Hiroko and Kanon are now able to test the sensors and make adjustments for better pea shoot growth.

Some risks that we need to look out for on the hardware side is to setup the wires and boards safely so that no water, moisture, or biomaterial will touch it. Depending on how the setup goes, we may need to make some containers and use zip ties to tie the hardware to certain parts of the greenhouse. With the TechSpark lab equipment and materials nearby Hiroko and Kanon, we can create containers if necessary. For the computer vision, the background of the greenhouse may be in the way of proper analysis, so to prevent that we will have a monochrome background to mitigate such issues, and Sarah is currently working with a box as her background for the CV analysis. The camera may also be difficult to adjust once it is placed in the greenhouse, so we are considering a RPi camera module stand and mount if we find issues fixing the camera onto the greenhouse.

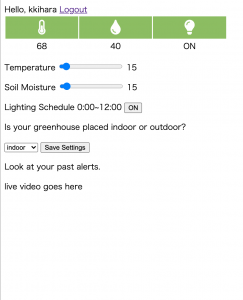

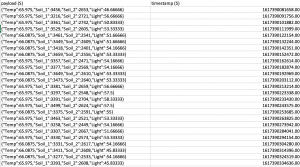

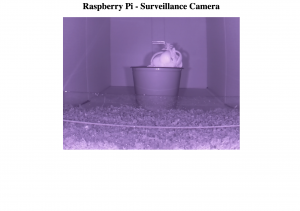

Sarah had to adjust some parts of the CV implementation systems. Since the real colors of the greenhouse are washed out in night vision, we’ve decided to only have CV analysis going on in daylight when the IR filter is switched back on. We found that it is unnecessary to have the CV running when the users are asleep and when plant growth is very gradual. Further, the leaf and flower detection along with the defect detection will only be applied from the young plant stage to the harvest stage and not in germination, since most defects occur during those growth stages. Kanon had to calibrate some values that the soil moisture sensors read to percentages for user readability, and with the deployment and user testing coming up, she may have to adjust some of the UI. On the hardware side, Hiroko needs to adjust the watering tube so that water is distributed more evenly and adjustments like the making a container may be needed when the system is integrated to the greenhouse this upcoming week.

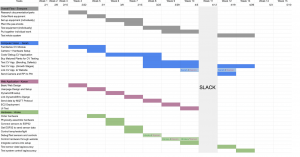

The schedule is mostly the same, but instead of shipping the RPi and the camera, Sarah has decided to bring the RPi and camera in May. Full integration of the greenhouse is therefore delayed by a week, but that gives us more time to work on our individual components and Sarah setting up the CV equipment herself will save more time for the integration process.

.

. .

.