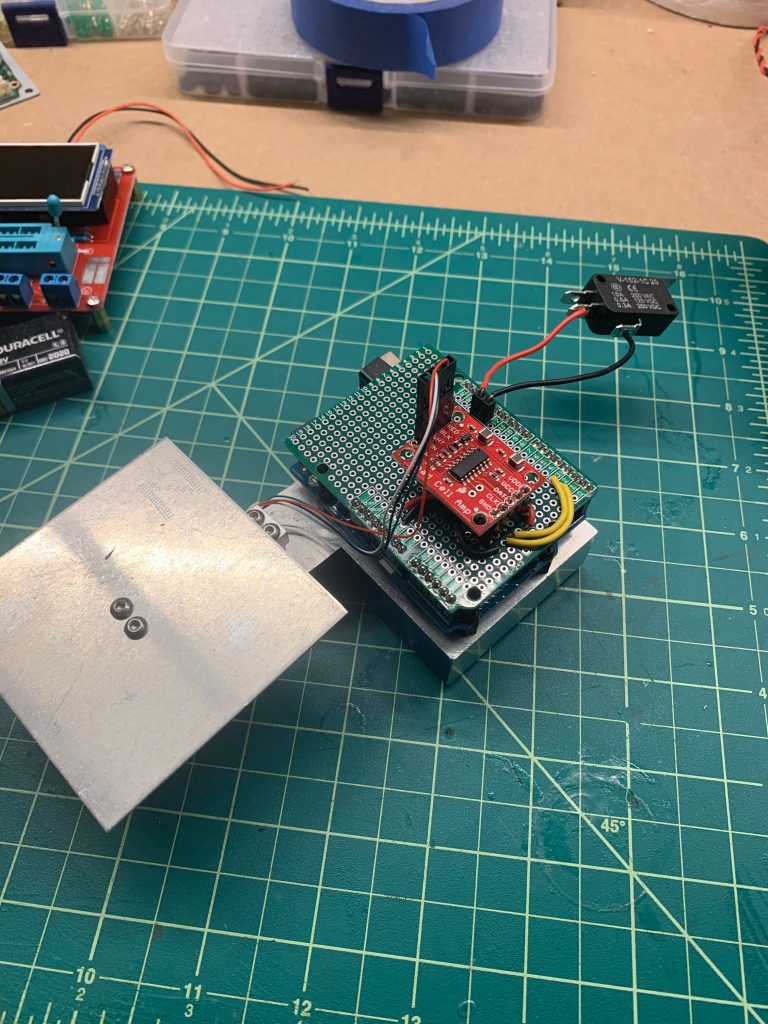

This week I worked finalized the TP load sensor integration with the rotation sensor.

The system uses an acrylic piece mounted inside the TP tube to trigger a contact switch mounted on the end of the TP axis. This triggers the start of a “wiping session” in the code, telling the Arduino to begin tracking the delta of the TP weight. The scale is precise to 0.1g, enough to detect ~1.2 sheets of commercial tp, or <1 sheet of residential TP. The “wiping session is terminated after a set timeout from the last trigger of the rotational switch.

We continue to be on schedule

Next week, I hope to:

- Work with James to integrate communication into the sensor

- Begin PCB designs for the TP sensor

Team Update:

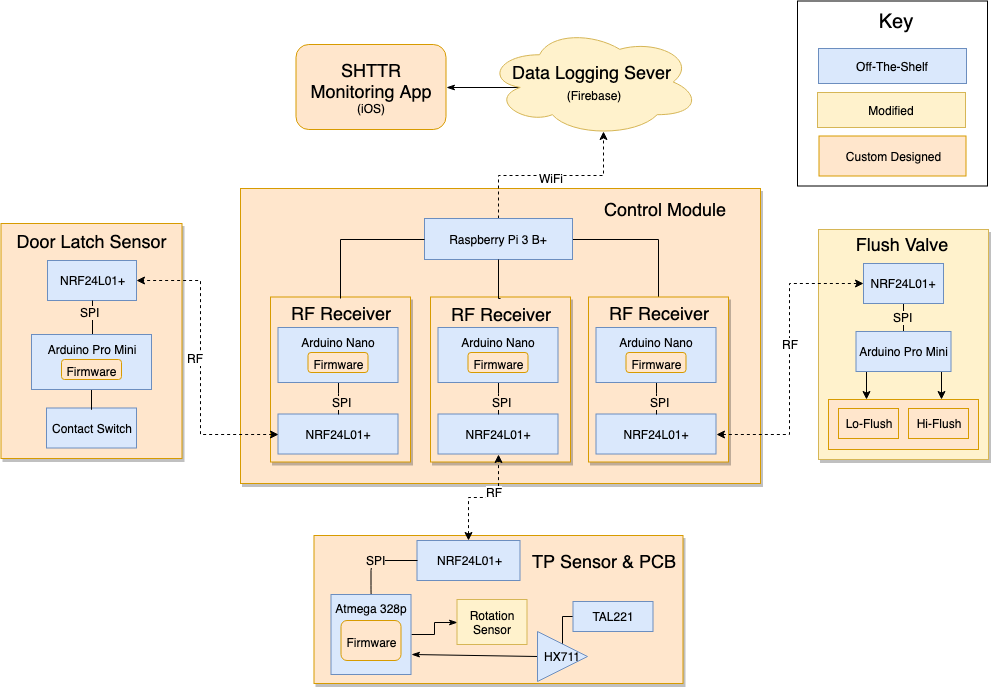

This week, we were preparing for the demo on Monday 4/1. We plan to have the TP sensor connected to a laptop, which logs data to the functional app. We have run into a fairly large issue with the overall Farsens system integration with the RFID reader. As such, we are behind the schedule for the initial plan for the demo, which included having the battery-free sensor integration. Although unable to accomplish this, we do have the MVP of which includes the toilet paper sensor, the application, and communication of data between them. We have sat down and discussed some modifications to the design of the system based on our struggles trying to get the RFID working. The changes are detailed in the following new block diagram:

This modification to the system would remove the RFID component, replacing it with a series of NRF24L01+ RF transmitters. This would allow us to still have effective wireless communication. This chip is well-documented, unlike the RFID we were working with before. Looking into the technologies being used, it would still be feasible to get back on track, as this wouldn’t require modifications to the TP Sensor (except for adding RF) and the app.

0 Comments