In preparation for the demo this upcoming week, I have focused mostly on integrating all the hardware components on the jacket.

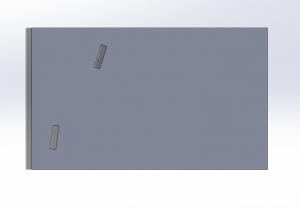

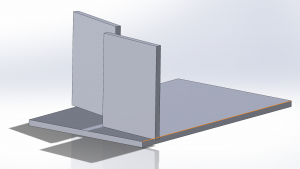

One of the major components is the LED matrix, which is large, making it hard to place on the jacket, and has the highest power consumption, requiring careful wire management. We decided that we wanted to put the battery pack on the top of the jacket, so we had to move the LED matrix down a bit on the back.

For putting the LED strips on the jacket, I considered several attaching mechanisms, including:

- Sewing pulley joints to zig-zag the strip

- Gluing the strip directly on

- Gluing the strip onto a clothe and then sewing the strip on

- Sewing the strip directly on

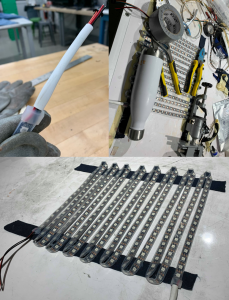

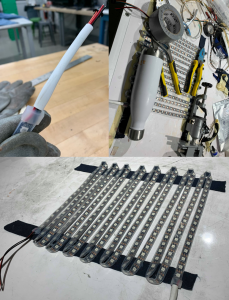

I went with gluing the strip onto a clothe and then sewing the clothe on the jacket. The reason for this choice is that the pulley joints depended too much on the sewing for the joints, which is risky. Gluing the strip directly on is not flexible, and sewing the strip directly on is not secure, and if we pierce the waterproofing sleeve, then we don’t have waterproofing anymore.

Gluing the LED strip sleeve was no easy task though…the following glues did not work:

- Hot glue

- Super glue

- EPOXY

- Acrylic Glue

- Gluestick

- Electrical tape

- Duct tape

You get the idea…it was a struggle. But it turns out there’s a special glue called Silpoxy that works brilliantly, and tada…

I also heat shrinked the LED strip wires for additional waterproofing protection.

I also soldered the vibration motor component of the jacket as well, and will finish the integration before the demo. Next steps are to sew everything onto the jacket, and do a quick Raspberry to Arduino comm test via Bluetooth.