This week, our team successfully conducted the final presentation, effectively showcasing the significant advancements made in our hardware system. The presentation highlighted the structural improvements to the gantry system, particularly addressing the friction issues caused by the charging cable interacting with the charging pad connection. To resolve this, I enhanced our CAD model by increasing the distance between the glass interlayers on the tabletop by 2mm and redesigned the charging pad housing. These modifications ensure a better fit for the charging pad and prevent the cable from rubbing against the tabletop, thereby improving the system’s durability and performance.

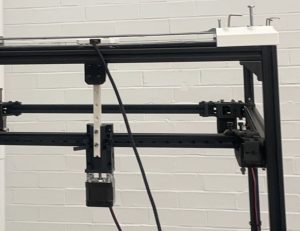

In addition to the structural enhancements, I dedicated considerable effort to unit testing and recalibrating the gantry subsystem. This involved fine-tuning the subsystem to accurately move specified distances in the XY direction and ensuring reliable interaction with the computer vision system. Moving from one end of the gantry system to another end, with 57 cm of travel distance, the average error rate for the system is about 1.8mm. We have also run several tests on Z axis manipulator and hardcode its value. Each time the travel distance of the Z axis has a 2-3mm error while trying to improve the stability, this margin of error is acceptable for the design.T hrough rigorous testing, we confirmed that the vision system accurately detects the coordinates of a cell phone and effectively directs the gantry to position the charging pad at the target location.

Looking ahead to next week, our focus will shift to further system integration and enhancing inter-system interactions. I will be collaborating with Bruce on state feedback detection and vision calibration for the gantry’s end effector, ensuring precise positioning after the charging pad is moved to its designated location. These efforts aim to refine the overall system functionality and ensure seamless operation across all components.

Overall, this week has been highly productive, with key improvements made to both the structural design and the functional integration of our gantry system. These advancements position us well for continued progress in the upcoming phases of the project.