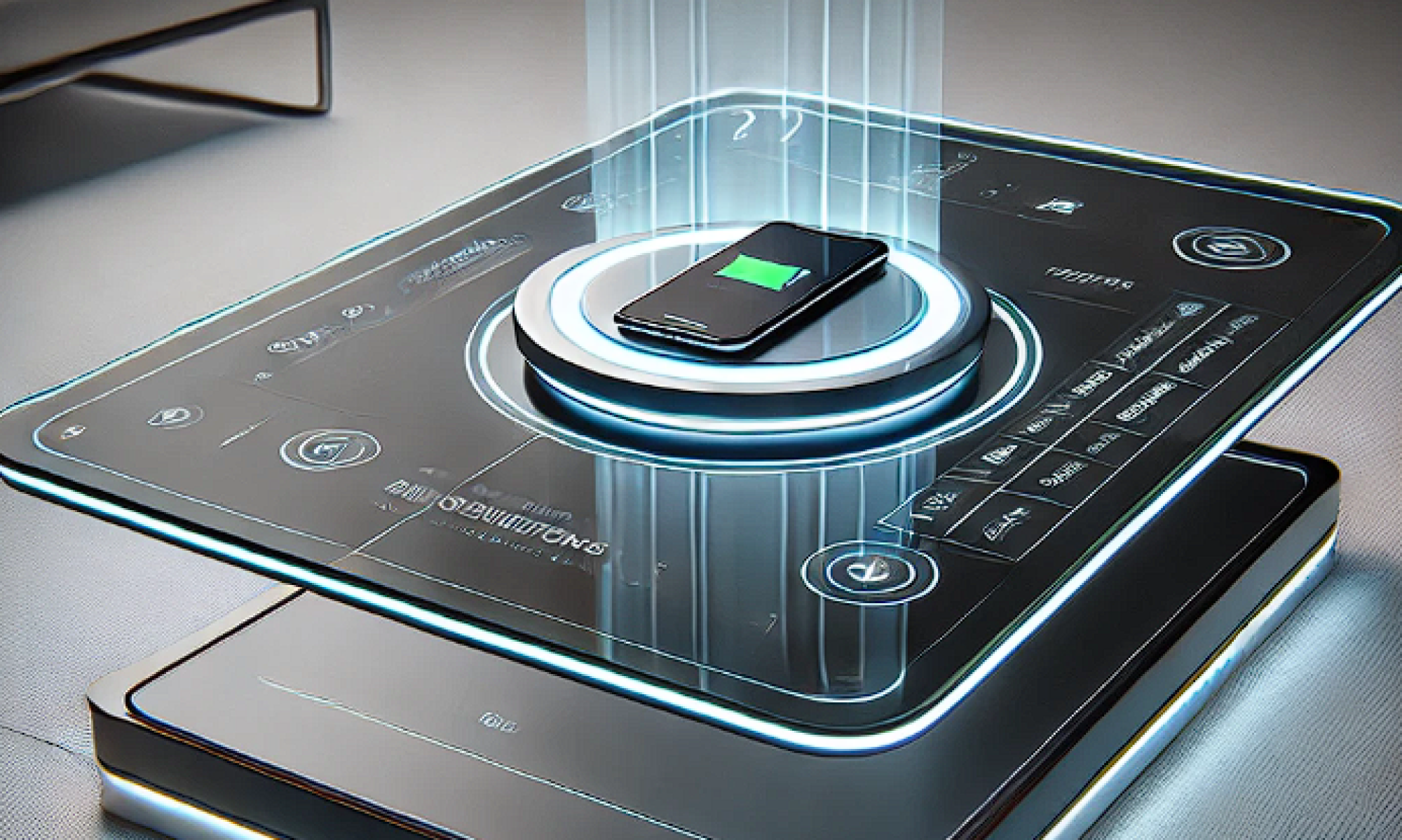

This week I continued to refine the hardware and control system for the gantry system. In order to ensure a close enough charging distance, I weighed the tradeoff between table thickness and charging effectiveness. Through testing, I found that a 3mm desktop ensures the best charging results i.e. charging with a case and without having to fully align the charging pad with the phone. However, the acrylic sheet we started with was not strong enough and its center section deformed very significantly and blocked the movement of the charging pad. On balance, I urgently purchased and cut glass panels and redesigned the CAD for the corner fixing parts, and tested to ensure that the charging pads would run silky smooth between the two layers of table tops, dragged by magnets.

I also debugged the motor driver and wiring for the up and down movement of the manipulator to ensure that it could perform the specified movement and drag the charging pad under the table. After experimentation, the gantry system now moves the charging pad well. At the same time, because the motor wiring is more confusing. I organized its wiring and centralized the motor driver into a cardboard box to avoid it receiving disconnection and other problems. Next week I’m going to focus mainly on improvements in the accuracy and workload testing of the system as well as the smoothness of the integration.

As you designed, implemented, and debugged projects, what new tools or knowledge did you find you needed to learn to accomplish these tasks? What learning strategies did you use to acquire this new knowledge?

As an ECE student, I started with no specialized knowledge of gantry systems. I referenced many belt designs for 3D printers and other three-dimensional gantry units from the internet. At the same time, the motor driver was more complex than we thought. Since I had not used a stepper motor professionally before, it took me a lot of time to debug the PWM signals. I browsed through Arduino user forums and YouTube tutorials to properly match our motor driver with the motor body.At the same time, since the design process requires a lot of rework, I have also brushed up on a lot of skills such as Solidworks and 3D Printing Slicing through online tutorials and learning from my mechanical engineering friends to help us efficiently complete our tests and improvements.