David:

This week, I worked on the functionality of having the Raspberry Pi control the pump. I created a python script that was able to turn on/off the pump and also control the flow rate of the pump with PWM.

I tested out the small peristaltic pump on different kinds of liquid and under different conditions.

Water at different voltage(all close to 12V): varies in undefined behavior, but all in the range of 62-78ml/min;

Water with pump at different heights relative to the water level: not much difference (at most 2ml);

Water with pump connect to different pins: not much difference (at most 2ml);

Other kinds of liquid compared to water at the same pins and same voltage: alcohol or alcohol mixed with water (about the same: 2ml difference); soda (I used sprite) (much slower: less than 40ml/min); coffee (cold brew: mixed with honey and cocoa) (faster: about 5ml).

I also worked on testing the other peristaltic pump that we had purchased, which is able to pump liquid much faster but with a lot less accuracy (100ml in less than 2s). The issue with this pump is that the hat doesn’t have enough power to drive the pump, so if we were to use it, we would have to use a seperate power source and a relay to turn it on and off. This pump will be used for the cleaning water as the amount of water that we will clean the funnel with does not need to be exact. I also was able to control two pumps at the same time with the Raspberry Pi. While we still need to make sure that the Raspberry Pi is able to handle more than 4 pumps due to the pin limitation on the hat, this was a good start for us.

For this upcoming week, I will be responsible for purchasing more electronic components for our project. For example, we need to buy three more peristaltic pumps for the drink liquids. In addition, we need to buy a ADC converter for the 12V power supply to the Raspberry Pi HAT.

Bill:

I tested the liquid level sensor. I used a plastic cup filled with water and moved the sensor up and down the cup. Whenever the sensor came in “contact” with the waterline, the sensor lit up, alerting us that it sensed the liquid. I also tested the liquid level sensor with other kinds of liquids. We wanted to make sure that the sensor was versatile enough to be able to detect liquids besides water. We were fairly confident that it would be but wanted to be certain. When we did test it, we found out that the sensor was able to accurately detect the various liquids, except for pure isopropyl alcohol. The sensor sometimes gave false negatives when put on a plastic container of isopropyl alcohol. I tried pouring the alcohol into different containers, but I still having issues with the sensor. I tried diluting the alcohol, and after that the sensor was surprisingly able to detect the liquid, which suggests that pure isopropyl alcohol has some chemical properties that makes it hard to detect.

In addition to testing the liquid level sensor, I also went to Home Depot to purchase the necessary materials for the platform for the glass (where the drink will be poured).

For this upcoming week, I will be working on constructing the platform with the load sensor. I will build out the platform from a physical standpoint and then hook said platform up to a power supply and multimeter to output the change in load on the sensor. If I am able to get done with that, I will go onto connecting the Raspberry Pi up to the load sensor see if I can get accurate digital readings of the weight. I will test glasses of different weights to see how to calibrate the cell to be able to detect glasses of various weight.

Connor:

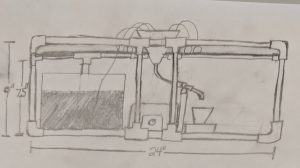

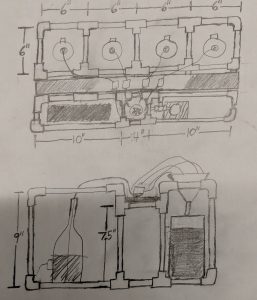

This week, I designed the scaffolding for the bottles, pumps, funnel, and valve. We are working on the skeleton of the project and will work on the covering in the subsequent weeks. The skeleton of the project will allow us to show our MVP for the midterm demos. Here are the drawings of the design of scaffolding:

As you can see above, this is the front view of the system. As you can see, you have a basin of water used for the cleaning water. In addition, we have the valve slightly offset from the funnel. The rationale behind this is that we can allow the magnetic mixer stirrer to get as close to the funnel as it needs to mix it while the valve can be clamped to some PVC piping a be a natural position to pour into the glass. If the base of the stirrer is too low for the system to properly mix drinks, we can add a false bottom to it to have it be closer to the funnel and thus the magnetic pill.

For the top and side views, you can see that we added a plank of wood in the middle of the system. The reasoning for this is to have a place for the peristaltic pumps for the bottles to be situated in such a place that allows their tubing to go to the bottom of their bottles while having access to the funnel.

I also tested the gravity-feed solenoid valve, but I was having some difficulty in getting it to be functional. When I hooked it up to the 12V DC power supply, the power supply would say that it was overloaded and would only output ~2.5V.

Next week, in addition to finish building the scaffolding of PVC piping, I plan on getting the valve to function properly, as in having it hooked up to an external power supply and having it properly open and close. Once I have the valve working, I will then begin working on connecting it to the Raspberry Pi and being able to control the valve from it. In addition, we hope to receive the magnetic mixer stirrer sometime early this upcoming week. With it, I will test it’s connection to the AC/DC control relay and then have it work with the Raspberry Pi and control turning the magnetic mixer stirrer from it. I also plan to design and construct the funnel in such a way that the tubes for the drink liquids and cleaning water can be used in the funnel. This will include drilling holes in the funnel and stabilizing the tubes at such an angle to ensure that they dispense liquid directly into the funnel as opposed to shooting out of the funnel.

Overall:

After the course of this week, we feel that we have made adequate progress. While we have made a decent amount of progress this week, we still need to further derisk certain aspects of our project. For example, we need to ensure that the valve that we purchased is a possible solution. If by the middle of next week we are having no luck in getting the valve to function properly, we will search for a valve that will meet our needs. Also, we need to make sure that we can control and pump multiple liquids simultaneously. To test such, we need to order the necessary parts on Tuesday to get them in as quickly as possible. By getting starting on testing as early as possible, we can increase the margin of error to ensure that we have adequate time to build out the hardware. Moreover, we need to further design the functionality of rinsing using either the bigger peristaltic pump which isn’t very accurate or another peristaltic pump (such as the one we are using for the drinking liquids).

Some parts of our system have been changed and/or elaborated upon, such as the scaffolding, and the explanation for such has been made in our individual responses.

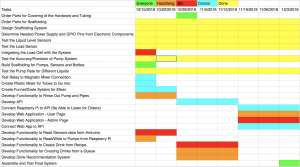

For our schedule, we were able to get all the necessary parts for the scaffolding. However, we are holding off on ordering the covering for Bartendo for reasons that I mentioned above. So in that sense, we will separate this into a separate task and work on it a few weeks from now. On the other hand, we have already begun working on writing capabilities to the pumps and that is showing great promise so we are a bit ahead of schedule on that front.