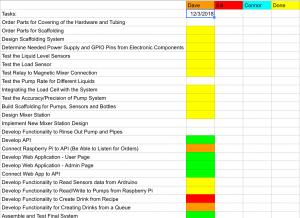

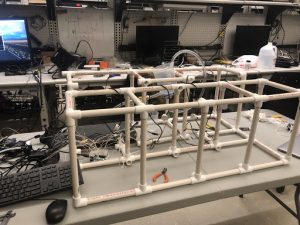

Here are some pictures of the Batendo project:

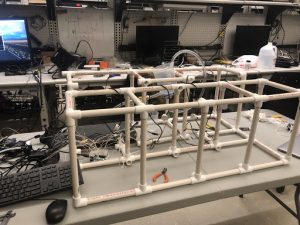

Picture 1: Overall scaffolding of Bartendo

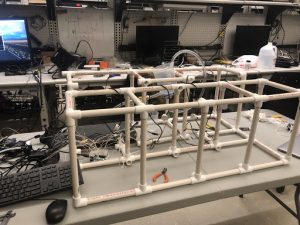

Picture 2: Mixing station of the Bartendo

Picture 3: Sensor system for bottles for Bartendo

Just another Carnegie Mellon University: ECE Capstone Projects site

Here are some pictures of the Batendo project:

Picture 1: Overall scaffolding of Bartendo

Picture 2: Mixing station of the Bartendo

Picture 3: Sensor system for bottles for Bartendo

Click the link below to take a look at our poster for the Bartendo project.

Bill:

I helped out with hanging up the components on the scaffolding, and worked on sealing a hole that we accidentally poked in the tubing. Then I connected the 4 new liquid level sensors that arrived this week to the Arduino, and changed the Arduino code to read from all four of the sensors simultaneously. I also had to change the code for communication between the Arduino and the Raspberry Pi to account for the extra data that we now have to send over. After I got those to work, I moved the platform with the load cell, the Arduino, the Raspberry Pi and the liquid levels sensors into the scaffolding. Afterwards, I tested the whole system again to see if it still worked. Then I connected the new power relay we got this week to the Arduino, and changed the Arduino and Raspberry Pi code to account for it. Then I tested the power relay to test if it could be controlled using the Arduino. Everything worked well together, so now we just have to hook up the new pumps we received, and test the web app to see if it can be used to send orders to the system.

Next week, I will work on ensuring the stability of the system through testing and help create the wooden casing for the system.

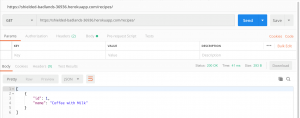

Connor:

This week, I completed the API and deployed it to Heroku. We were initially thinking about using AWS ElasticBeanstalk, but due to the simplicity of a Heroku API, we went with that instead. We also plan on doing the same for the web application.

I was also able to test out the API. As you can see below, I have tested out one of the endpoints from the hosted API on Heroku using an API testing client.

I also have begun hooking up the web application to the API. I was able to retrieve data from the API to the app, such as recipes for example.

Next week, I will work on the API (currently one of the endpoints that is needed for Raspberry Pi needs to be done) and tie the API and web application together. I will also finish up any of the UI changes that need to be done to the application.

Dave:

This week I was able to assemble the two hats (solder) onto the RPi and test (and configure) the pumps on the two hats to run them simultaneously controlled by RPi.

Moreover, we did some of the assembly of our system. We were able to connect all the hardware parts, including RPi, Arduino, sensors, mixer, valve, and pumps. Also, we hung up the mixing station and the valve. We were also picking out the final containers for the liquid. You can see that in the pictures below.

For next week, we should finish the encasing of the project and I should finish reading and writing data from APIs with the RPi (as soon as Connor finishes the API).

Overall:

With this being our last weekly progress report, we can say with confidence that we can achieve a demo-able system by this upcoming Friday. The only thing we will probably not be able to fulfill is the drink recommendation portion of the app. However, we had that as a stretch goal from the start. The major components of the system (the hardware, API, user/admin app) should be done. The only design change that we can think of is that we are planning on not using WebSockets but instead HTTP polling to make requests to the API. It’s not a major change to the system, and we feel confident that it won’t cause any hiccups in this last week. While we do have to do a bit of tidying up of the UI, the software portion is in a good state for the demo on next Friday. The hardware has mostly been set up. We do also have to create the casing for the hardware using wood. We are aiming to have the system set up by Wednesday to give us enough time to create the casing for Friday. By having testing mostly finished for Wednesday (for the hardware at the very least), we can provide ourselves with any of the buffer time that might be needed if we were to experience any technical difficulties.