May 11, 2015: Final Product

The system came together well, and is functioning better than our original requirements dictated. Currently, we can scan with 2.5-degree steps in 8 minutes, and 10-degree steps in about 2 minutes (it scales linearly). The face generation is done completely on the device, using an attached SD card for raw memory, and the generated PLY file is shown as a file in a mass storage device when the scanner is connected by USB to a computer. In other words, it looks like a flash drive with the single file "scan.ply" on it after a scan.

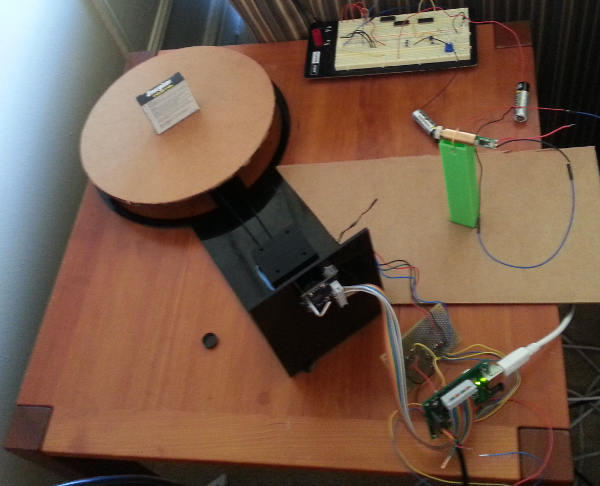

We also mounted all of the components in fixed locations on a few layers of cardboard so the entire setup is sturdy and doesn't shift.

Top View

The final version, from above.

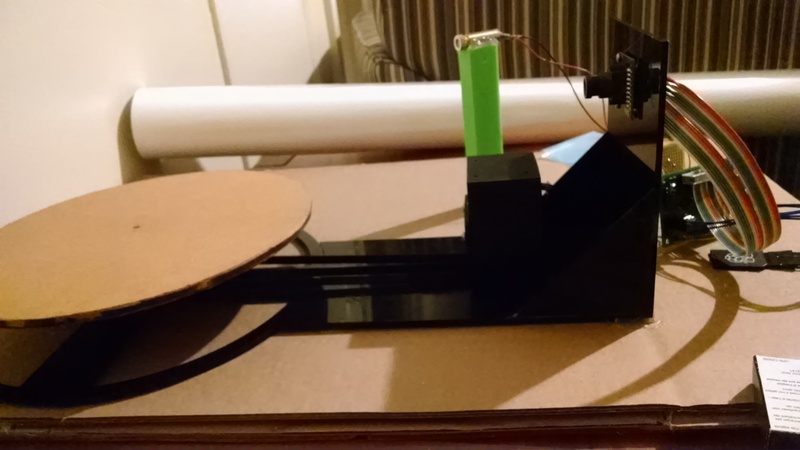

Side View

The final version, from the side.

Scans

Here are some example scans that we have done, with high resolution (2.5-degree steps).

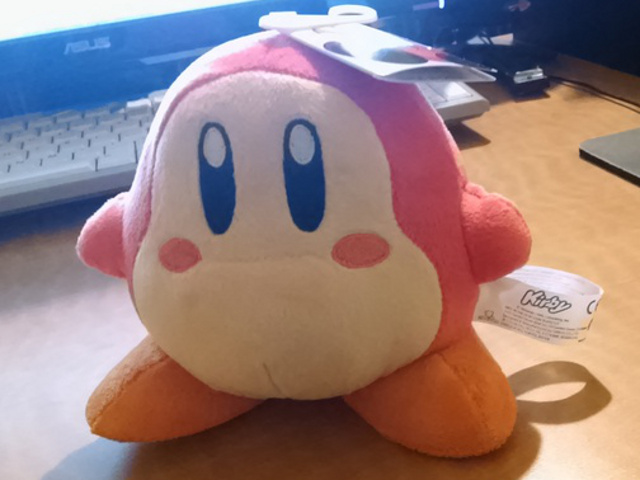

A stuffed toy (a Waddle Dee from the Kirby games). Download

A metal helmet, propped up on a box. Note that there is a lot of noise due to the texture and shininess of the surface. Download

A windup toy, propped up on a box. Notice how some of the faces could have been generated a bit better. Download

A figurine of the Bowser character from the Mario games. Download

A reindeer PEZ dispenser. Again, notice how the faces around the antlers could be improved. Download

A random object we found around. Download

A piece of cake on a plate which we took a bite out of. No original image available because we ate it.

Note that the plate was very shiny and caused a decent amount of noise. Download

Final Video

Final Paper

View our final report here.

Known Issues:

- The camera sometimes cuts out due to white balancing issues. Optimally we would disable white balance and manually tweak the white balance, exposure, and gain values.

- The camera sometimes has a weak connection and doesn't assert its values on the line strongly, making for incorrect reads.

- Face generation isn't great. We are using a relatively naive approach, which could be improved for much better results.

- Some smoothing can be done on the points to make the resulting model less jagged.

April 26, 2015: First Scan

Board, motor, laser, and camera are all connected and functional. As of today we've finished our first complete scan, taking a grand total of four minutes. Currently the camera module is returning a considerable amount of noise preventing our current triangulation algorithm from properly identifying the shape.

Top View

The current setup.

First Scan

ScannerDude's first step!

Known Issues:

- Urgent: Camera module generates a considerable amount of noise.

- Structure needs to be finalized.

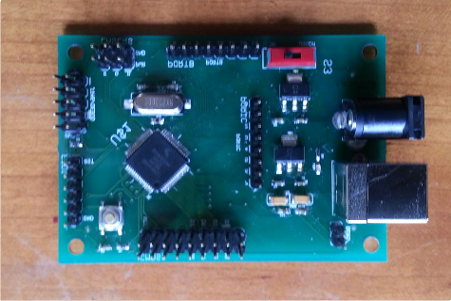

March 30 2015: PCB

Board and all required components finally arrived. MCU was properly tested to ensure all outputs and input were working as intended. Codebase prepared for basic image processing and desktop connection.

Top View

USB connector, power source, and MCU

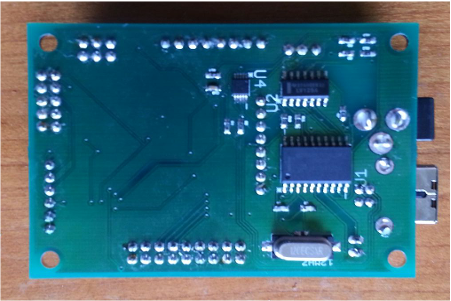

Bottom View

Used for debugging and programming purposes, not required for final design.

Eagle Files

Known Issues:

- TS3USB VCC is 5V, chip specifications require 3.3V.

- MCU and USBDM share reset.

- Can only connect as USB 1.0 (?).

- GPIO Pins does not supply enough current to power laser module.

- Insufficient storage space.