Design Finalization

This week, our team finalized the design of the smart charging table system, the main change we have are:

- Gantry System: We have chosen a gantry-based system to move the charging pad. Instead of physically attaching the charging pad to the gantry or a robotic arm, the pad is constantly powered and placed between two layers. The gantry system will employ magnetic forces to move the charging pad to the desired location beneath the device.The main reason we change from robots to gantry system and separate magnetic charging pad is because in this case we do not need to worry about the wiring issue. For robots, since we need to apply power to them, the powering wire would cause many troubles to robots, which would affect the accuracy of it, and our current design would eliminate such problem

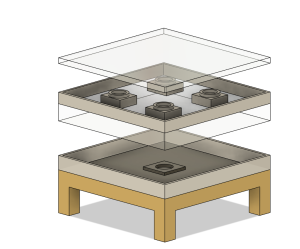

CAD Model Development

A major milestone this week was the successful development of the CAD model for the entire system. This included:

- Detailed CAD of the system: Showing how the whole system works.

- Layering structure: Visualizing how the charging pad will be placed between the two layers while still enabling smooth movement via the gantry system.

The CAD model provides a clear representation of the mechanical design and will serve as a reference for building the physical prototype.

App Prototype Creation

We also developed a prototype of the mobile app that will interface with the charging table. The app includes:

Charging status, device name, battery percentage, temperature, and estimated time to full charge.

The settings feature allows for future customization and functionality expansions. This prototype will be used for real-time communication between the table and users to ensure proper tracking of the charging process, and it will also serve as a feedback system.

Component List & Part Sourcing

We have also made progress on assembling the component list for the smart charging table:

- Researched motors, sensors, and magnetic components that are suitable for the gantry system.

- Explored charging pad options to ensure continuous power delivery while allowing movement within the system.

- This work brings us closer to being ready for the procurement phase and building the first physical prototype.

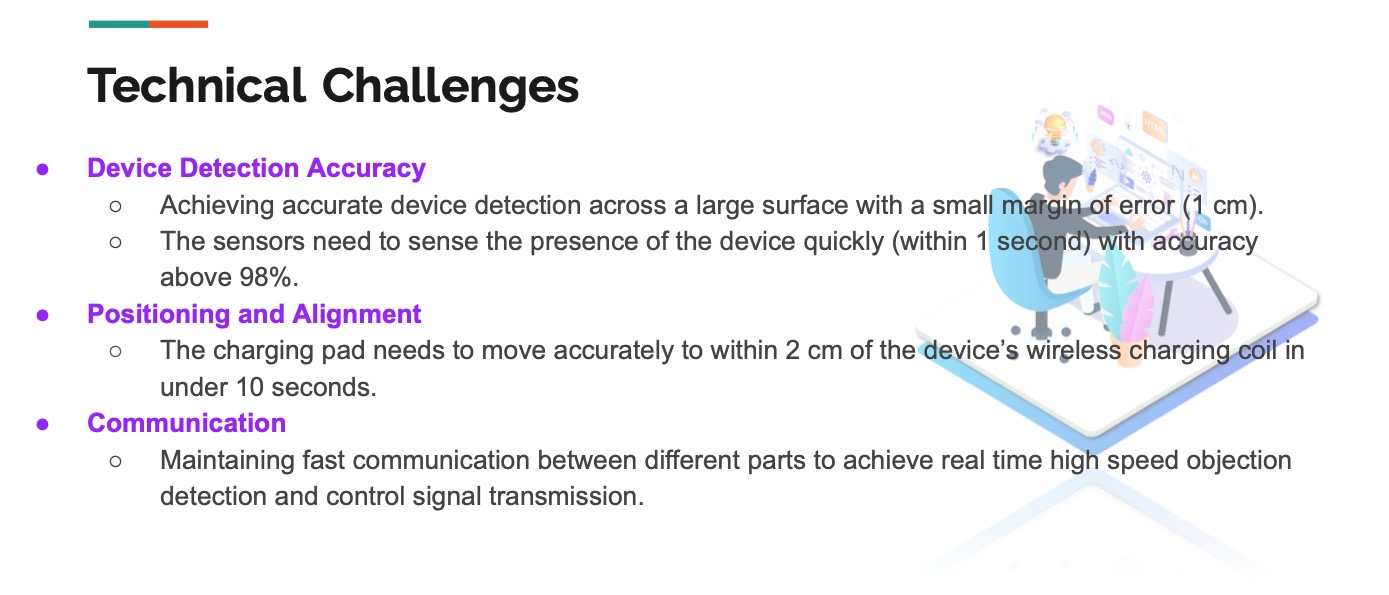

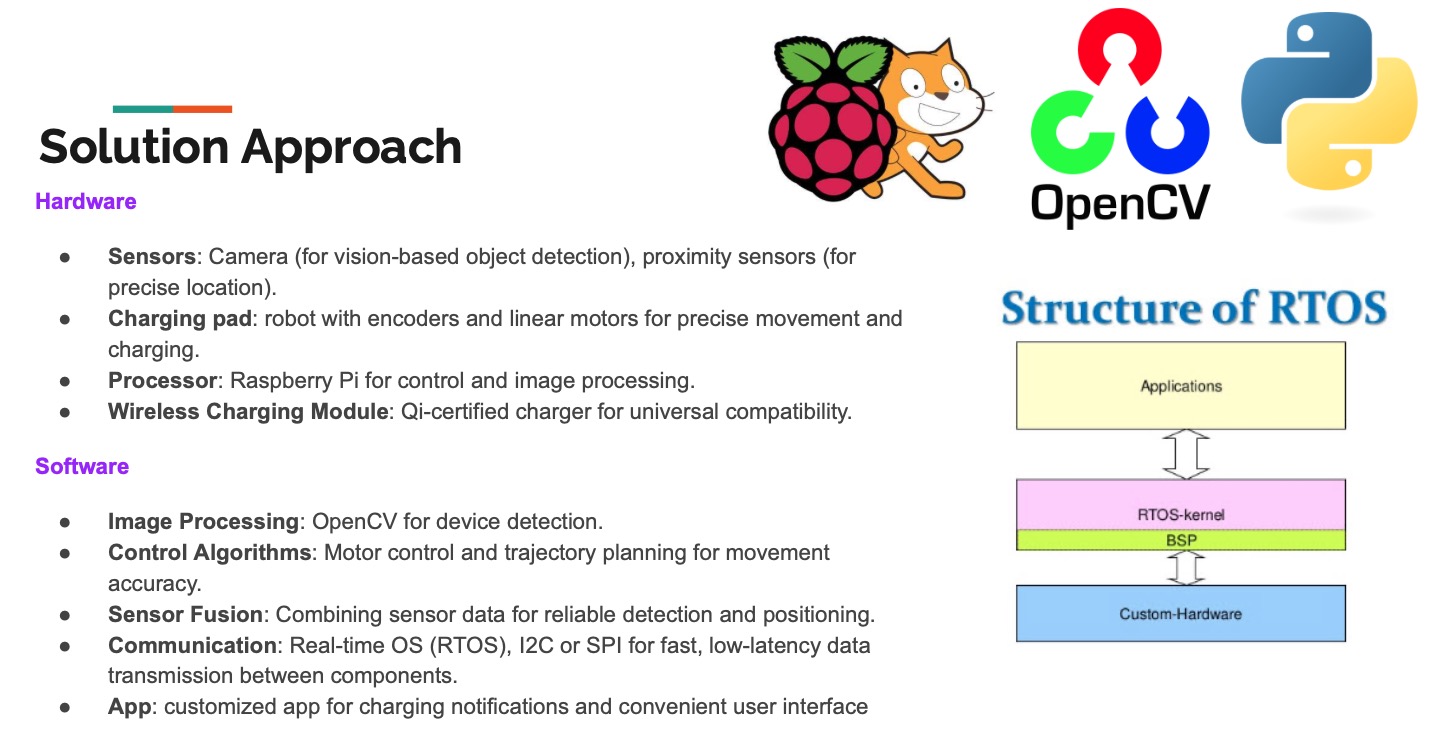

Design Presentation

The team has also started working on a comprehensive design presentation as required, and finished most part of it.

The whole team is currently on schedule, and for our next week’s plan:

- Continue refining the CAD model with detailed dimensions and tolerances.

- Finalize the component list and begin sourcing parts for the physical build.

- Begin working on the communication protocol between the app and the table hardware.

- Try to prototype the charging pad model.

- Improve on the App features.