This week, Albany and I had planned on doing some testing with the detection code and the sensors, but we ran into some problems with the STM again. We spent some time debugging the system overall. I discovered that some of my LED code wasn’t working. We fixed most of those problems. Since Jason has fixed the STM communication, I have to fix a problem with the interrupt code on the Arduino. Luckily I have a version of working code with slower updating, so I can compare the broken, faster code to the working, slower code to isolate the problem.

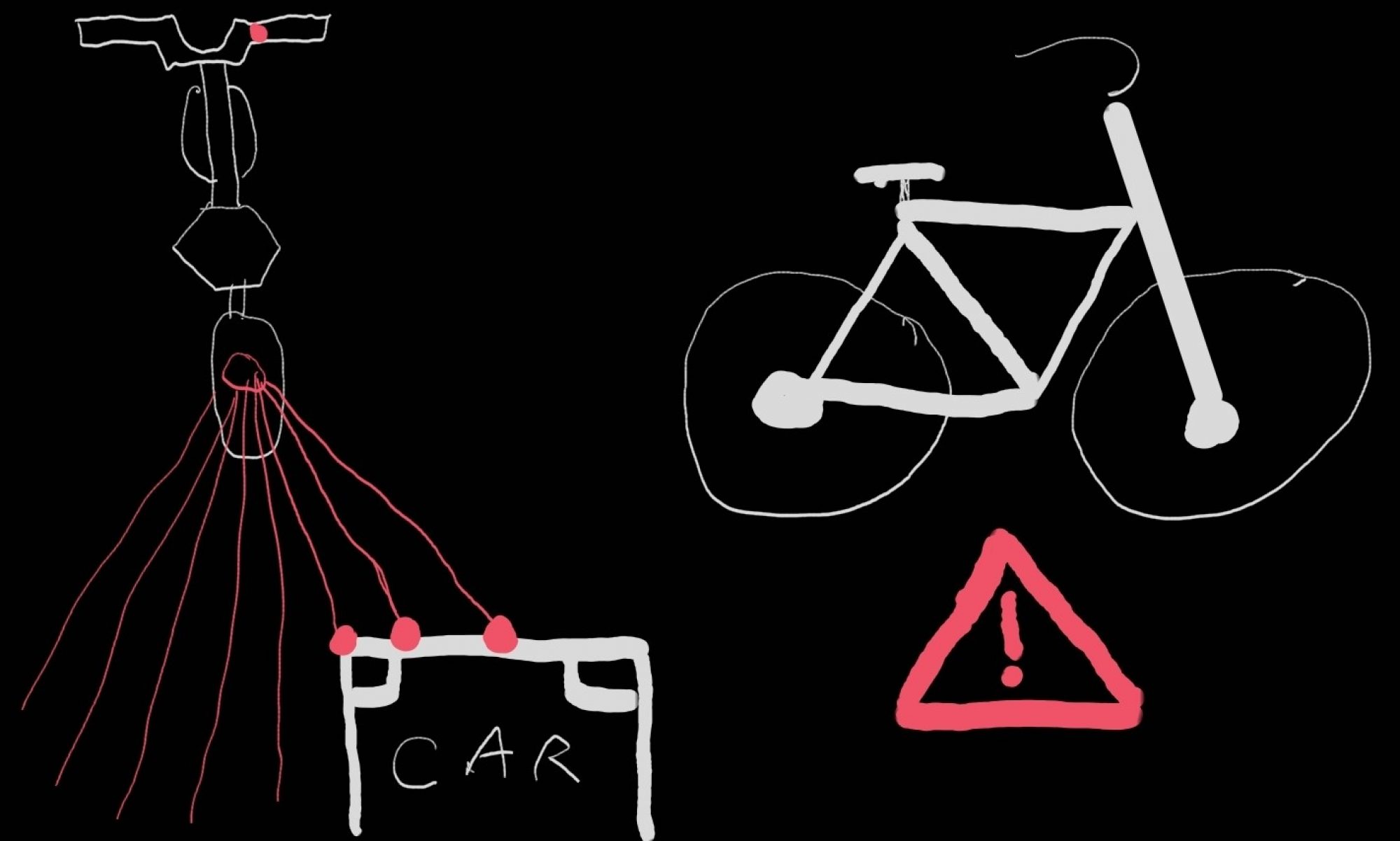

Today especially, everything decided to break. I was trying to refine the turn signals, but then one of them stopped working. Turns out the LED contacts had disconnected from the strip. I had also added a green LED on the handlebars to indicate that the system is on. Suddenly, that had stopped working as well. Again, by hooking up the working sets of LEDs, I determined that it was the contacts. I cut off the broken LED and Albany soldered the LEDs again. These two sets of LEDs were the only two that we hadn’t hot glued. Hopefully the hot glue prevents this in the future like it has for the other. Strain relief would’ve been good for the LEDs had we known that this was a problem The contacts for the LEDs are so small and the wires don’t have much area to contact.

I’ve also decided to CAD another mount. We had talked about not creating another mount because of time constraints, but we have room in the budget, and it will hopefully make it easier for us to do the final assembly. We don’t have space for the turn signals on the current mount, and we couldn’t find screws small enough to attach the sensors. I think printing is the best way to create an attachment for the sensors in this case.

My plan is to fix the Arduino code and send the CAD model for printing by Monday evening, that way we will have plenty of time to do the video and get some more testing in.