Final Video 12/12/2021

Jason’s Status Update 12/4

Since Thanksgiving, I have been working hard to engineer a GPIO-based solution to transmit LED codes as required in the design, in order to circumvent the problems we had with serial communication. That has since been finished and tested. Although there are some problems working with the full set of LED control routines on the Arduino, a reduced set works and the oscilloscope measurements from the STM look normal, so we’ll have to look on the Arduino further to solve this problem.

I also helped with the assembly of the system, soldering and heat-shrinking some wires from the STM to the Arduino and sensors. The assembly was completed and I managed to load a version of code into the system that controls the front LED lights accurately reflecting sensor readings and signal processing results. This marks the completion of the duties that were assigned to me, so I can now dedicate my time to help with testing and debugging as part of the final step of the project.

Team Status Update 12/4/21

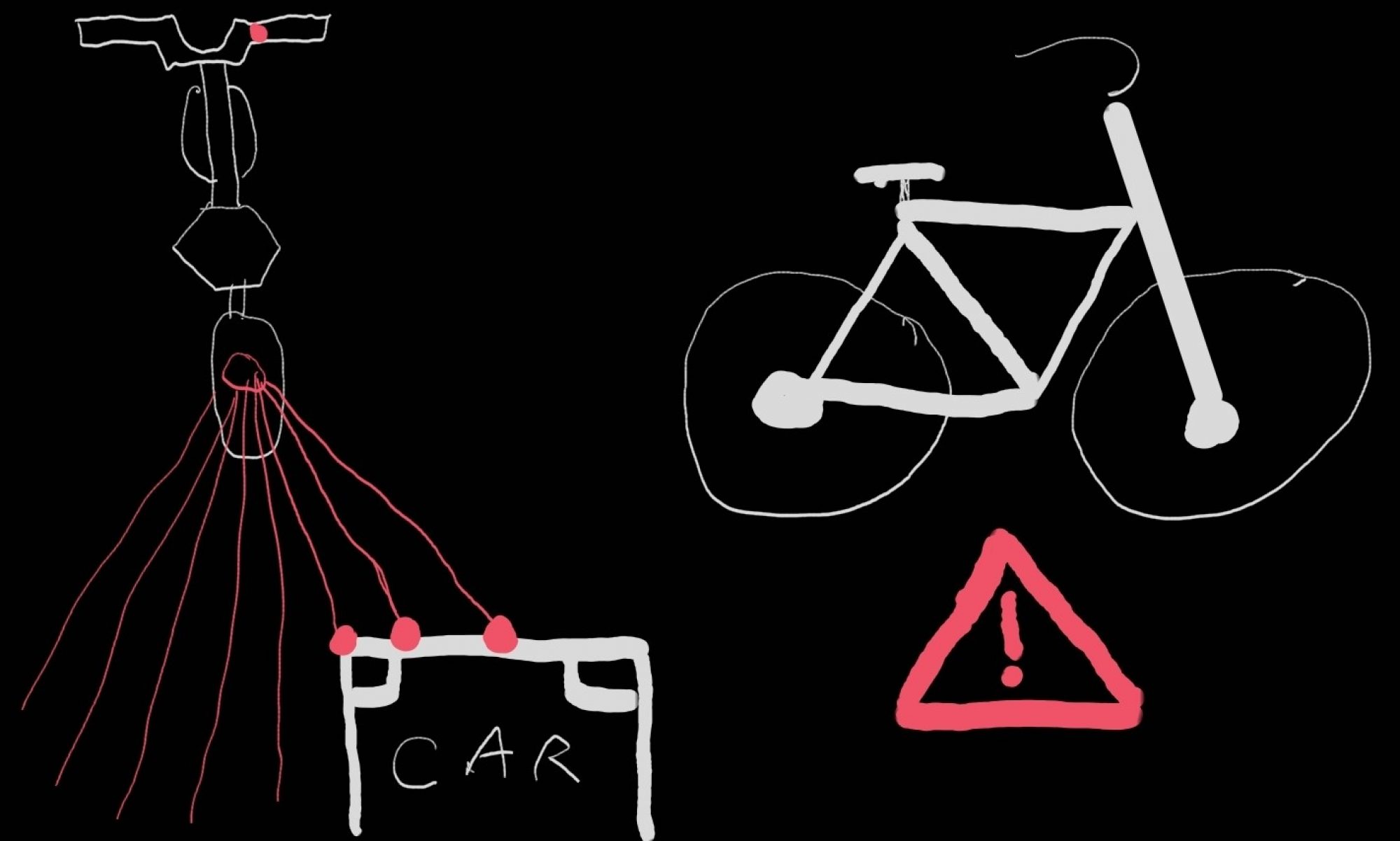

Last week, we got the system running off of battery power. We’ve added JST-SM connectors to the batteries and the LED power connectors so that we can disconnect and debug more easily. The ON/OFF switch has been connected to the solder board, and the turn signal button has been connected as well. All of the hardware has been connected. The final mount will be printed next week so the physical component of the project will be finished after that is printed.

We’ve been having some problems with the communication between the STM and the Arduino. The GPIO from the STM works, but the Arduino code needs to handle the data more quickly for us to meet our timing requirements. Next week, we are going to test how the system handles and outputs the sensor data, rather than testing just subsystems.

Emily’s Status Update 12/4/21

This week, Albany and I had planned on doing some testing with the detection code and the sensors, but we ran into some problems with the STM again. We spent some time debugging the system overall. I discovered that some of my LED code wasn’t working. We fixed most of those problems. Since Jason has fixed the STM communication, I have to fix a problem with the interrupt code on the Arduino. Luckily I have a version of working code with slower updating, so I can compare the broken, faster code to the working, slower code to isolate the problem.

Today especially, everything decided to break. I was trying to refine the turn signals, but then one of them stopped working. Turns out the LED contacts had disconnected from the strip. I had also added a green LED on the handlebars to indicate that the system is on. Suddenly, that had stopped working as well. Again, by hooking up the working sets of LEDs, I determined that it was the contacts. I cut off the broken LED and Albany soldered the LEDs again. These two sets of LEDs were the only two that we hadn’t hot glued. Hopefully the hot glue prevents this in the future like it has for the other. Strain relief would’ve been good for the LEDs had we known that this was a problem The contacts for the LEDs are so small and the wires don’t have much area to contact.

I’ve also decided to CAD another mount. We had talked about not creating another mount because of time constraints, but we have room in the budget, and it will hopefully make it easier for us to do the final assembly. We don’t have space for the turn signals on the current mount, and we couldn’t find screws small enough to attach the sensors. I think printing is the best way to create an attachment for the sensors in this case.

My plan is to fix the Arduino code and send the CAD model for printing by Monday evening, that way we will have plenty of time to do the video and get some more testing in.

Albany’s Status Update 4 DEC 2021

Emily and I were going to test the entire setup, but upon arriving noticed some issues with STM arduino communication so I have spent this week debugging with the group. When testing the STM I noticed the waveforms were not reaching adequate triggering level for the arduino, Jason was able to fix this the next time he came in. The two heat-wrapped LED connections failed and so were redone with the addition of hot glue. The communication cable for the arduino and STM was accidentally severed and also redone. I also soldered connections for the turn signaling switch. Jason and I at the end of today were able to get the singals code showing on LEDs and will now work on refining the values in that code for real life.