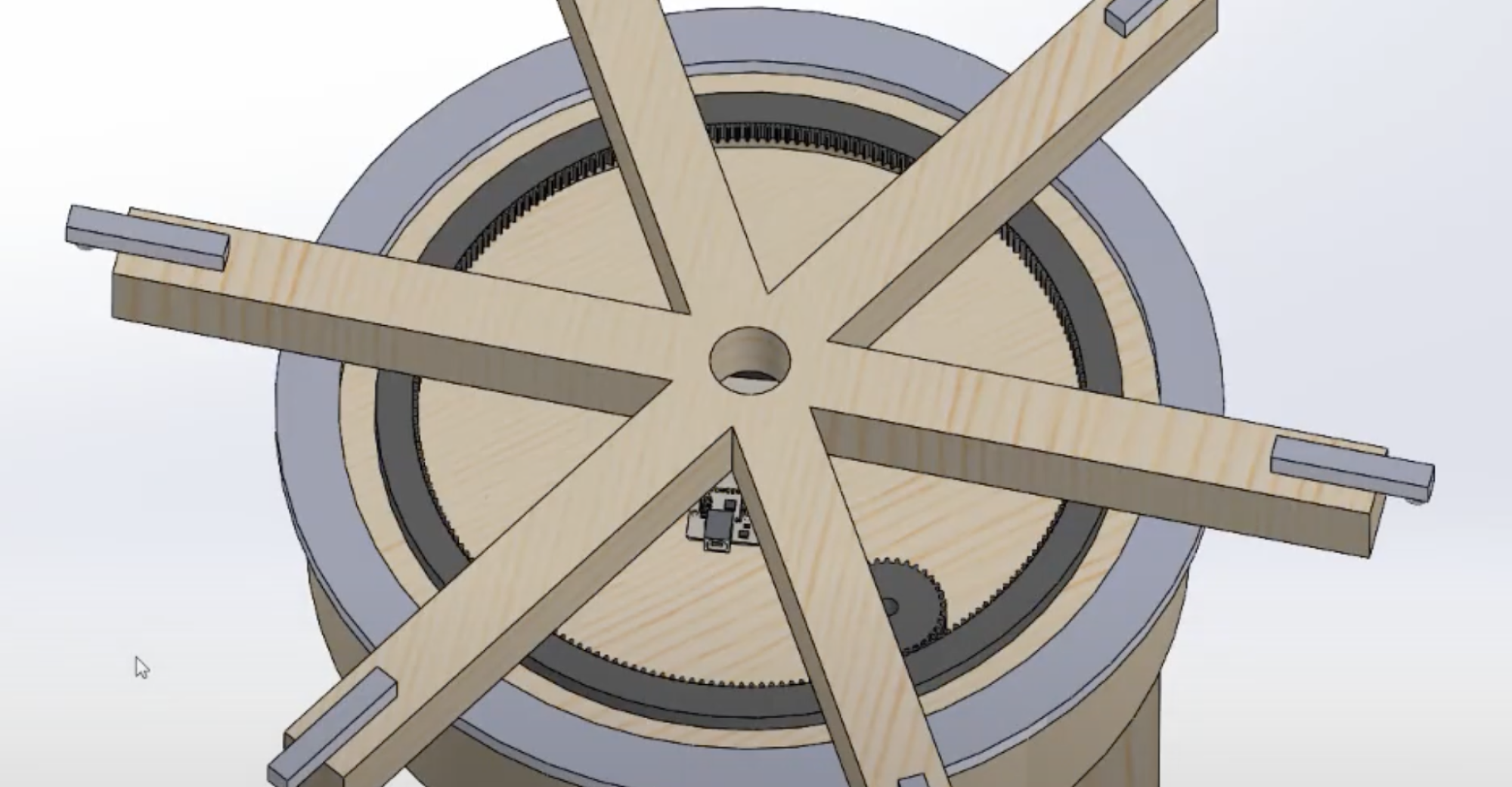

- This week, I mainly worked on preparing for the interim demo. This involved doing some end-to-end testing with the hardware components and the facial recognition system. There were issues relating to wireless transmission between the Python code for the facial recognition and the Arduino code, so I worked with my team members to fix those issues. We realized that the readline function that we utilized would block on many trials, so we had to deduce where to problem was and how to fix it. We thought about various solutions like flushing input and output buffers, but ultimately realized we had to add some delays in various locations of our programs to ensure that the subsystems were in sync. In addition on this integration, I tested the Nema 34 motor and helped write code to control the motor upon an check-in or check-out process. This involved spending time in the TechSpark wood shop to carve a hole in the rack to place the motor and mounting the motor sturdily to the rack using brackets and nails. Additionally, I worked on code to control the motor, allowing it to rotate to a user’s position on the rack.

- My progress is slightly behind schedule. I have worked on testing various components of our system, including the load cells, motors, and wireless transmission. However, the complete system has not been tested together thoroughly, with members outside of our group. In addition, the LEDs which indicate to the user whether they have successfully placed their items on the rack has not been permanently installed, so a bit more time in the wood shop is required to do that. In order to catch up, I will need to add the LED and do further testing using volunteers to ensure that the system works as a whole.

- Next week, I will work on adding the LEDs to the rack. I will also work on doing end-to-end testing. Further details are provided above.

- Although we notice that our system works mostly as intended, I would like to further optimize delays for the check-in and check-out process. The delays added for transmitting information make it so that our timing requirements (taking less than 5 seconds for a using to be recognizes) are not meant. As a result, I would like to find the smallest delays that allows message transmission without blocking behavior. Secondly, I would like to test if each hook on the rack can withstand the maximum weight ( 20-25 pounds) previously set in our use case requirements. This will involve place 20 pound backpacks on our rack and seeing if the motor can successfully rotate that much weight. In a similar regard, I would like to ensure that even with weight imbalances, the motor can successfully rotate the items on the rack. I will do this by placing a large weight (20 pounds) on one side and nothing on the other. I will also check-in 6 times to fill the entire rack, then remove all items on one side, to ensure that the motor successfully rotates the weight and that the thread on the gears are not impacted.

Carnegie Mellon ECE Capstone, Spring 2024 | Doreen Valmyr, Ryan Lin, Surafel Tsadik