Progress

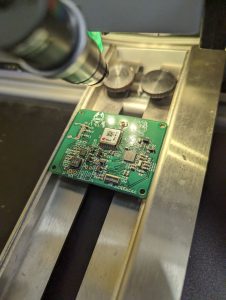

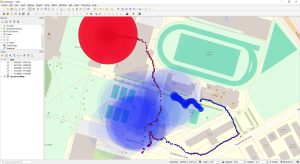

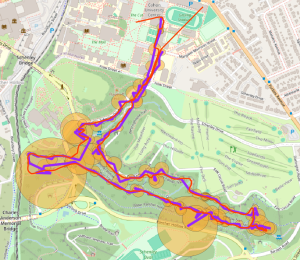

Earlier this week, we did the final assembly of the watch and brought it out to Schenley Park to do a field test:

Apart from this field test, all of our team members have been occupied with other obligations and courses wrapping up this week. We have no new risks, and no major design changes have been made.

Testing recap

We’ve done quite a few formal and informal tests throughout the development of Landhopper. Aside from our continuous basic testing of the device’s operation indoors while developing its firmware, we often made quick excursions out of the lab in order to check the GPS behavior. These were done at various times of day, and in varying weather conditions (in the first photo below, it was raining, so we placed the development board in a plastic bin to keep it dry). These tests were very informal (we rarely recorded our results other than taking photos) but they proved to be extremely effective for iterative testing of our code: we caught many, many GPS and battery-related bugs this way.

Besides these very informal tests, our formal tests were more diverse: for example, the characterization of our motor power source was one of these, and from the test we found that while mechanical energy harvesting with a motor is definitely viable energy wise, it would take much more iteration to produce a version that is small enough to fit in a watch. This confirmed our choice of the solar panel as our power source, so no design change was made as we had already designed much of the watch with a solar panel in mind.

Our aforementioned Schenley Park field test was looking for several pieces of information: how accurate our GPS logging is, how reliable our SD card saving and loading is, and how long our battery lasts. From the test, we found that our GPS logging accuracy and capacity is within our requirements and that our SD card loading works correctly and quickly. We discovered after the test that we had accidentally set the GPS to log more often than we had intended to, which definitely affected our battery life results, but accounting for this error mathematically we determined that our battery life should still meet our requirement. Design wise this test resulted in few changes, as it mainly served to confirm our requirements; however, it did lead to us correcting the GPS log interval, along with determining that our GPS antenna should be placed on the side of the watch in such a way that it faces the sky when the user’s arm lies completely slack.

Our comfort test is our next planned formal test. We have not been able to run the test yet, but we plan to have several participants wear the watch in several environments and answer a questionnaire about it. This test will serve to check our weight and comfort requirements and also to inform any final changes to the design of the watch’s case.