This week, we worked on finalizing design choices in preparation for the design review next week. We also attended Professor Dueck’s class, where we could collect some preliminary data points for dB, check out some of the different rooms available, and ask for user feedback of what kind of product they’d prefer.

What are the most significant risks that could jeopardize the success of the project? How are these risks being managed? What contingency plans are ready?

One of the most significant risks we identified today is the possibility that the sizes of the materials we have chosen make it impossible to meet the sizing requirements we have set. We are managing this risk by relaxing our sizing requirements. We are also trying different prototyping methods that still try to minimize size as much as possible.

Were any changes made to the existing design of the system (requirements, block diagram, system spec, etc)? Why was this change necessary, what costs does the change incur, and how will these costs be mitigated going forward?

We have created a battery life requirement of 8 hours, which is the maximum amount of music-interaction time without a break that was brought up in conversation with participants in the music studio. That creates the need for these relatively large batteries.

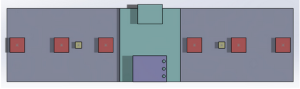

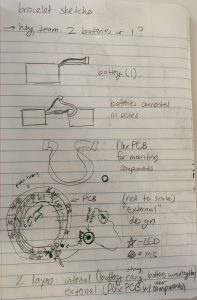

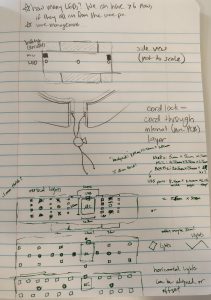

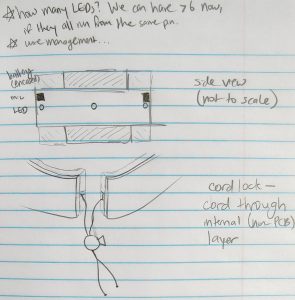

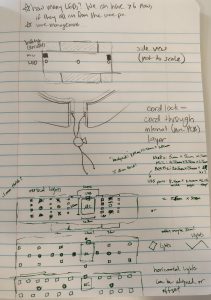

We are eliminating our thickness requirement. When considering preliminary sizing, we realized that the given dimensions of the parts we have agreed on (battery, microcontroller, LEDs, microphones, and boost converter) would not be feasible given the thickness and height requirements we had created. From there, we had a choice of eliminating the height requirement (creating a chunky bracelet) or the thickness requirement (creating a cuff/armband style of bracelet). We chose to eliminate the thickness requirement because eliminating the height requirement would make the bracelet stick out too much to be comfortable to wear (and would also make it more prone to damage). One concern with this solution is that it could interfere with wrist movements; given that our potential users include pianists, this is an important concern. We decided that the bracelet should be adjusted to be worn sufficiently far back that it does not cover the wrist or interfere with wrist movement. We will still attempt to minimize thickness, and rely on user feedback to determine if this is a satisfactory solution.

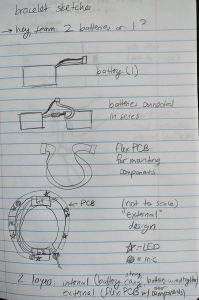

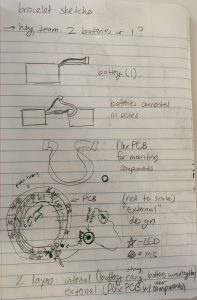

In our weekly meeting, we confirmed that connecting our components via a PCB is necessary. The alternative had been to individually solder/wire each component together, but this is probably impossible because of the size of the components. We are going to connect all non-battery components together on a flex PCB, and include a place to plug in the battery. This results in an increased cost for our system (from ordering the custom PCB).

Also in our weekly meeting, we discussed the idea of using 2 small batteries (instead of 1 large one); the battery life requirement dictates that we use larger batteries, but maintaining a relatively small size is important. Our plan is to use 2 small batteries, one on either “side” (above or below the wrist) of the bracelet, and have them wired in series to provide one red/black battery connection to the PCB. The risk is that, if done incorrectly, this can ruin both batteries; however, we are going to verify that our plan is safe before carrying it out, and take safety precautions while wiring the batteries together. In addition, if we test the bracelet and discover it uses less power than we thought, it’s probably easier to decrease the number of batteries than to increase it retroactively.

Provide an updated schedule if changes have occurred.

We have pushed forward tasks related to materials to account for the delay in finalizing and therefore in ordering materials. The tasks covering finalizing materials, ordering and receiving parts, electronic prototyping, Arduino-Bluetooth connection, LED signal setup, and the Bluetooth-webapp connection have all been moved forward to the week of February 25th. Also, software task deadlines have been moved forward because it took some time to get familiar with React Native; therefore, the deadlines have been moved to the 23rd and 25th, respectively.

This is also the place to put some photos of your progress or to brag about a component you got working.

Here are some sketches of our physical design.

How will our product meet a specified need…

with respect to public health, safety, or welfare? [Freda]

As mentioned in our introduction page, hearing loss was the leading sensory disorder in the US. Other than obvious uses such as listening to music and friends, our ears are also important to help with balancing, and even mild hearing loss doubles the risk of dementia [1]. In addition, people may not be as good at accurately interpreting the “loudness” of sound vs the actual decibel value, due to our ears being more sensitive to certain frequencies [2]. An objective way of measuring decibel levels, such as a phone app, would be nice, but inconvenient to pull out every time you want to check. Thus, a wearable device such as a bracelet would be a helpful way to monitor volume continuously throughout the day. This can be useful for musicians or other workers in loud environments, or anyone who wants to be more mindful of their surroundings. Once people are more aware of potential risks, they can take steps to mitigate and protect their hearing preemptively.

[1] The Hidden Risks of Hearing Loss | Johns Hopkins Medicine

[2] Equal-loudness contour – Wikipedia

with respect to social factors? [Lucy]

Our bracelet meets social needs by providing a convenient method for users to be more aware of their overall sound surroundings. With the adjustable light and color customization, our goal is to offer a product that caters to a diverse set of users, extending beyond those with full sight. Individuals with disabilities, like colorblindness, can also fully use our bracelet by customizing the colors to best suit their needs and preferences. Additionally, in settings where bright, flashing lights may be inappropriate, the bracelet can be customized to emit a softer glow. The light intensity can easily be adjusted to suit whatever the current social setting is.

with respect to economic factors? [Katherine]

The bracelet-webapp system is not meant to replace existing decibel meters and apps; therefore, it should have no effect on the production and distribution of these goods. While its goal is to create mindfulness of sound levels, the overall effect of this mindfulness remains to be seen. It is possible that increased mindfulness leads to users producing or consuming less music, because they are limiting their exposure. However, it is also possible that increased mindfulness will give users a better knowledge of when to take breaks, letting them engage with more music and therefore increasing their overall production and consumption.