What are the most significant risks that could jeopardize the success of the project? How are these risks being managed? What contingency plans are ready?

We had a few issues with fabrication, wires breaking, sensors disconnecting, and fitting the assembly in the bottom compartment. We resoldered our assembly, with a much more reinforced structure, and are printing a slightly taller bottom compartment.

Were any changes made to the existing design of the system (requirements, block diagram, system spec, etc)? Why was this change necessary, what costs does the change incur, and how will these costs be mitigated going forward?

We moved away from a pressure plate and to an FSM based on the ultrasonic sensor to measure bottle stability. This will simplify the system, reduce weight, and slightly decrease power expenditure.

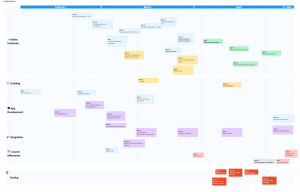

Updated schedule: