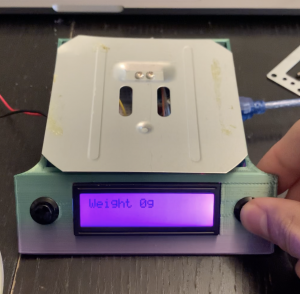

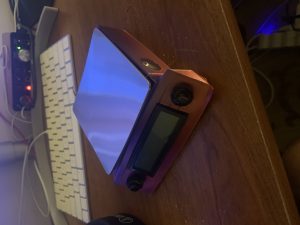

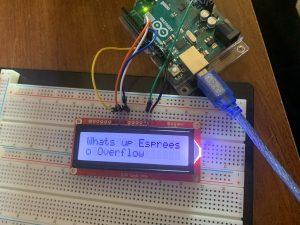

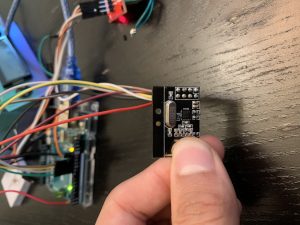

This week I put together the final assembly of the scale and tried to tie in the nRF24 to the application in order to get the weight readings. I was able to implement a timer with the scale and a reset function which is shown in the pictures below. In addition I did a lot of filming and recording of the final video in order to present on the final presentation day

.