As you’ve now established a set of sub-systems necessary to implement your project, what new tools are you looking into learning so you are able to accomplish your planned tasks?

To accomplish the hardware tasks planned for this project, I have had to learn how to use various software tools, along with a handful of physical tools.

The main software tool that I have been learning to design the PCBs for the project has been KiCAD. In the past, I have worked with Altium and EasyEDA but I wanted to branch out and learn more tools. EasyEDA served me well for a handful of designs but I wanted slightly more professional software, and one with a larger community. Although I also have experience with Altium, I personally do not enjoy it for personal projects, and I wanted to familiarize myself with the workflow associated with software other than Altium. Learning KiCAD primarily consisted of familiarizing myself with the location of various options and menus, such as customizing the DRC rules to match those of JLCPCB. I also had the opportunity to learn how to import symbols from Digikey and create/import footprints for parts. In the past I have either been able to find parts in the built-in catalog or in my company’s parts library, so it was good to learn the process of creating my own parts. I also had to learn how to create a precise board outline and mounting holes, which I have not had experience with in the past. In previous projects, I have just created a board and then created a mount to fit it in CAD, but for this project, my boards must mount onto existing hardware such as a Raspberry Pi. I have also been learning new skills in Arduino to test my hardware. For example, I have learned how to use the NeoPixel library to run the LEDs on the PCBs as well as learned how to detect interrupts with the Teensy and operate the D-flip-flops on the PCBs in order to accelerate my testing.

In terms of physical tools, I have been learning to work with PCB stencils and surface mount soldering. I have dealt with some surface mount soldering of 0402-0805 resistors and capacitors, but not in large quantities or anything more complex. Additionally, in the past I have always hand-soldered these parts. However, since we need around 14-15 of the fretboard PCBs, I am learning how to use PCB stencils, solder paste, and hot plates in order to expedite the soldering process. I have also been learning about a variety of sensors in our quest to find solutions to some of our sensing problems. This consists of learning how capacitive touch sensors work, as well as how the inductive and piezoelectric pickups used in many guitars function.

For the future, I am mainly interested in learning how MIDI files work a bit more so that I am more familiar with the work being done by software and firmware and can better integrate the hardware with these systems.

Weekly Update

This week I primarily worked on the assembly and testing of the fretboard PCBs and the design of the Pi-Hat.

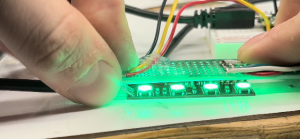

The assembly of the fretboard PCBs went well. This was done using the SMD stencil and a hot plate. In total 5 were assembled for Tushaar to use for testing. The pad for the current limiting resistor was replaced with a surface mount diode. The resistor will be added between the fret pad and the fret, so the safety of the system is not compromised by this. The functionality of the LEDs was tested, along with the D-flip-flops used for driving each fret high.

Top: One of the fretboard PCBs on a hot plate

Bottom: Initial tests of the LEDs on the fretboard PCB

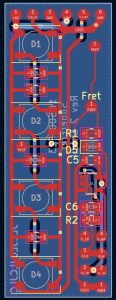

There are a couple of changes that need to be made to the PCB, most of which were implemented this week. The first change is adding a pad for the SMD diode in series with the current limiting resistor. The next change was to switch out the through-hole pads with pads on just the surface of the PCB. If solder flows though the through-hole pad it can result in an uneven bottom of the board, making mounting it more difficult. The next change was to make the PCB narrower by around 1.5mm. The initial measurements of the PCB were taken from a photo, and as a result, the PCB is slightly too wide to fit next to the 14th fret. The final change that needs to be made is to adjust the spacing of the LEDs. Currently, the spacing is reasonable for the middle of the guitar, but by making a few variants of the board, we can better match the spacing of the strings. The updated board layout is shown below

D1-D4 on the left are the LEDs. The top pads are the connections for the LEDs, and the bottom right ones are for the fret-driving flip-flop, which is on the right side of the board.

This week I also worked on the Pi-Hat PCB. The main change to the plan for the PCB is to offload the strum detection to a perfboard. The circuit needs a lot of tuning and this can be better done on a perfboard. This reduces the risk of the strum detection not functioning.

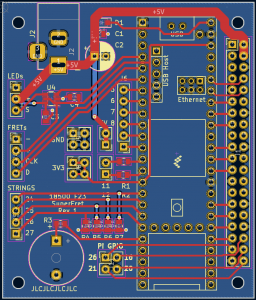

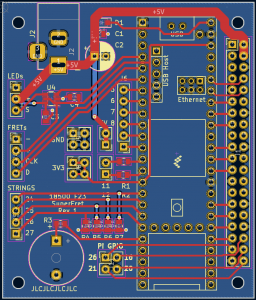

The PCB consists of the following components:

- A 5V barrel jack connector with filter capacitors. The 5V directly powers the Pi and LEDs and the Teensy is powered through a Schottky diode. This prevents backpowering the micro USB port on the Teensy, allowing the Teensy to be plugged into a computer while the system is also powered. It also prevents the USB port from attempting to drive the LEDs, which would draw too much current.

- The Teensy 4.1. A handful of the I/Os are sent directly to pads for future needs. 4 pads have external pull-down resistors and will be connected to the strings of the guitar. 10 of the I/O are routed directly to Pi GPIO pins allowing for communication. There are currently no plans to use all 10 of these, but this enables expansion in the future.

- A header to mate directly to the header on the Pi. In addition to the GPIOs routed to the Teensy, 4 I/O pins are broken out to pads for future use

- An active buzzer driven off a Teensy PWM pin. We can PWM the power to the buzzer to control the volume of the buzzer. A resistor pad is also included for current limiting the buzzer, although the current plan is to place a jumper on this pad.

- A 3.3V to 5V logic level converter to convert the 3.3V signal from the Teensy to a 5V signal for the LEDs. This may or may not be needed according to testing, but according to the LED datasheet the signal should be at least 3.6v

The current layout of the board is shown above. The Pi header is on the right side and the Teensy is the component to the left of the headers. The top left is the power barrel jack. Along the left side is I/O and at the bottom of the board is the buzzer.

For the most part my progress is on track. The fretboard PCBs still need their LED spacing revised, but this can be done fairly quickly once the desired spacing is determined. The Pi-Hat PCB design is ahead of schedule. These boards will likely be ready to be sent out in the same order, reducing the shipping costs incurred. The PCB assembly turned out to be faster than I expected, so this will not take as long as indicated on the schedule.

The DigiKey cart has also been compiled for the PCB orders, so that can be sent out this week.

The final thing that I worked on was the strum detection circuitry. It is mostly working on a breadboard so I hope to perform some final testing of that before soldering it up.

My main deliverables for next week will be ordering the PCBs and sending out the DigiKey order. I also hope to solder the strum detection circuit on perfboard.