One of the primary concerns brought up regarding the SuperFret project is that the metal frets of the guitar will be driven to 3.3V. When the string contacts the frets of the guitar, they will be driven to 3.3V as well. Since the user will be in contact with the guitar strings, concern has been raised regarding the system’s potential safety hazards. Fully understanding any safety concerns with our project is our number one priority, since as developers of a product, we have no right to put users in the way of any degree of risk. Users of the system may be unfamiliar with regulations and standards regarding safe voltage and current levels, so it is our job as designers to ensure that all safety considerations have been addressed.

Before ever selecting our project topic, we fully considered the risks to the user and determined that they were non-existent. In the time since selecting our project, we have further researched this topic to confirm the conclusion that putting 3.3V on the strings poses no safety risk.

According to IEC 61140:2016, Extra-Low Voltage is defined as less than 50V RMS for AC signals and less than 120V for DC signals. The IEC defines Extra-Low Voltage signals as having a low risk of electrical shock. The IEC further defines the Safety/Separated Extra-Low Voltage classification, which is used for voltages so low that even in the event of a system fault, there is no risk of electrical shock. To fall into the SELV category, systems must not expose users to voltages of 60VDC or higher for more than 200ms. Our intended solution for applying voltages to each fret will consist of pulses of 3.3V measured on the order of tens of microseconds, meaning our system would fall into the SELV classification.

Additionally, OSHA 1910.303(g)(2)(i) states that voltages above 50V are to be considered hazardous, with very rare reports of burns resulting from 12-24V car batteries. All incidents reported by OSHA 1910.303(g)(2)(i) at these voltages resulted from the voltage source coming into contact with a ring or watch worn by the user, and were at voltages 3-4x what we will be using. As such, we are confident that by requiring users to not wear any metal watches, rings, or bracelets, there is no risk of shock with our system.

For our proposal, we required that in dry conditions, our system falls within the IEC TS 60479-1 AC-1 classification, which defines a signal that is imperceptible to humans. This requires a current under 0.5mA to flow through the body. Dry skin typically has a resistance of at least 50kΩ, although assuming a worst-case scenario of 10kΩ, this will correspond to a current of 0.33mA flowing through the body. In wet and/or sweaty conditions, we will require that our system adheres to the IEC TS 60479-1 AC-2 classification, for which signals are perceptible but do not affect muscles. This classification requires under 5mA of current for continuous signals, although we will limit our system to 1mA worst case. To do this, we will put a 3.3kΩ resistor before the 3.3V signal connects to the fret, meaning that no more than 1mA can flow through even a direct short circuit. By doing this, we are confident that our system will pose no risk to safety.

Other factors that we considered were environmental and economic. By requiring permanent modifications to the guitar to be made to install our system, we must not unnecessarily increase the waste of resources or money. This was one of the many considerations that led to our requirement that the guitar should still feel and play normally when the system is not in use. Although the system will modify the guitar, the normal functionality will not be affected, and therefore if the user does not want to use the system, there is no need to purchase another guitar. While a removable system using a flexible PCB that spans the entire fretboard may be possible, to reduce excessive design risks, we decided to steer away from this option in favor of smaller modular PCBs spanning the guitar.

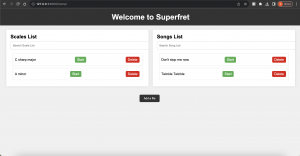

In addition to working on our project proposal presentation and trying to consider as many aspects of our project as possible, this week we worked on acquiring a Raspberry Pi from the ECE supplies and researching guitars. We were worried about picking up strumming from ambient noise, but in our research, we learned that many electro-acoustic guitars use piezoelectric pickups at the base of the strings to directly measure the vibrations of the strings. Getting a guitar with this system and tapping into the output of the piezoelectric sensor will likely provide us with a signal that is significantly more resistant to external sounds and movements. We hope to finalize our decision this weekend on a guitar so we can progress further with preliminary testing and implementation.