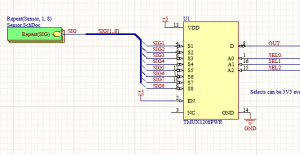

This week, we worked on validating our sensing architecture as well as the chess board PCB schematics and layout. We also worked on incorporating Stockfish’s move generation into our legality checker.

The biggest risks that our project faces are part shipping time and part stock. We are managing these issues by doing schematics and picking parts early as well as by monitoring stock of any components that are low. We are also looking at alternative vendors that may have more stock. One contingency plan is that we can have a list of drop in replacements for certain PCB components. Another risk is that something is done incorrectly on the circuit boards. This risk is being managed by having all group members look over the design before ordering. We likely will have enough money left over to order a second revision if absolutely necessary, but the circuit boards themselves should have room to rework and modify the design.

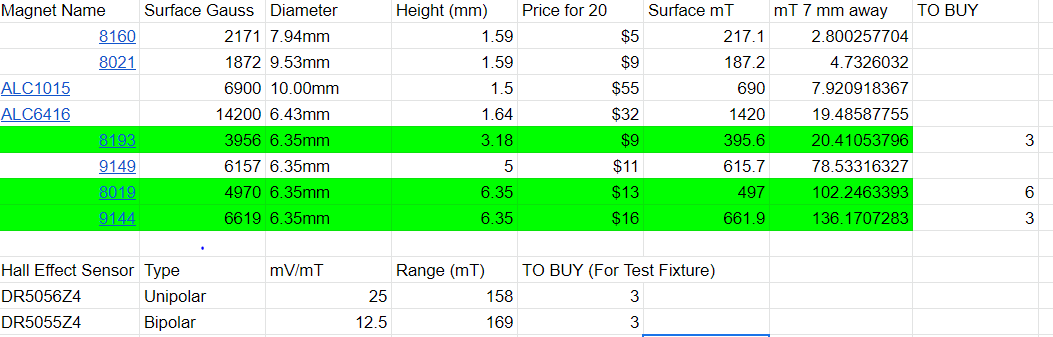

One change we wanted to make to our requirements is going from simply being able to detect piece color to detecting each piece type using the hall effect sensors. This was initially considered as a change because the initial color detection is not enough to cover all scenarios of pawn promotion. Before we finalize this change, we will do more investigation into magnet choices to ensure this is possible. The cost of this is that we will spend a little more money buying components that may not be on the final product. This cost will be mitigated by saving extra money on PCB components where possible.

We are largely still on track with our original schedule.

Recent Comments