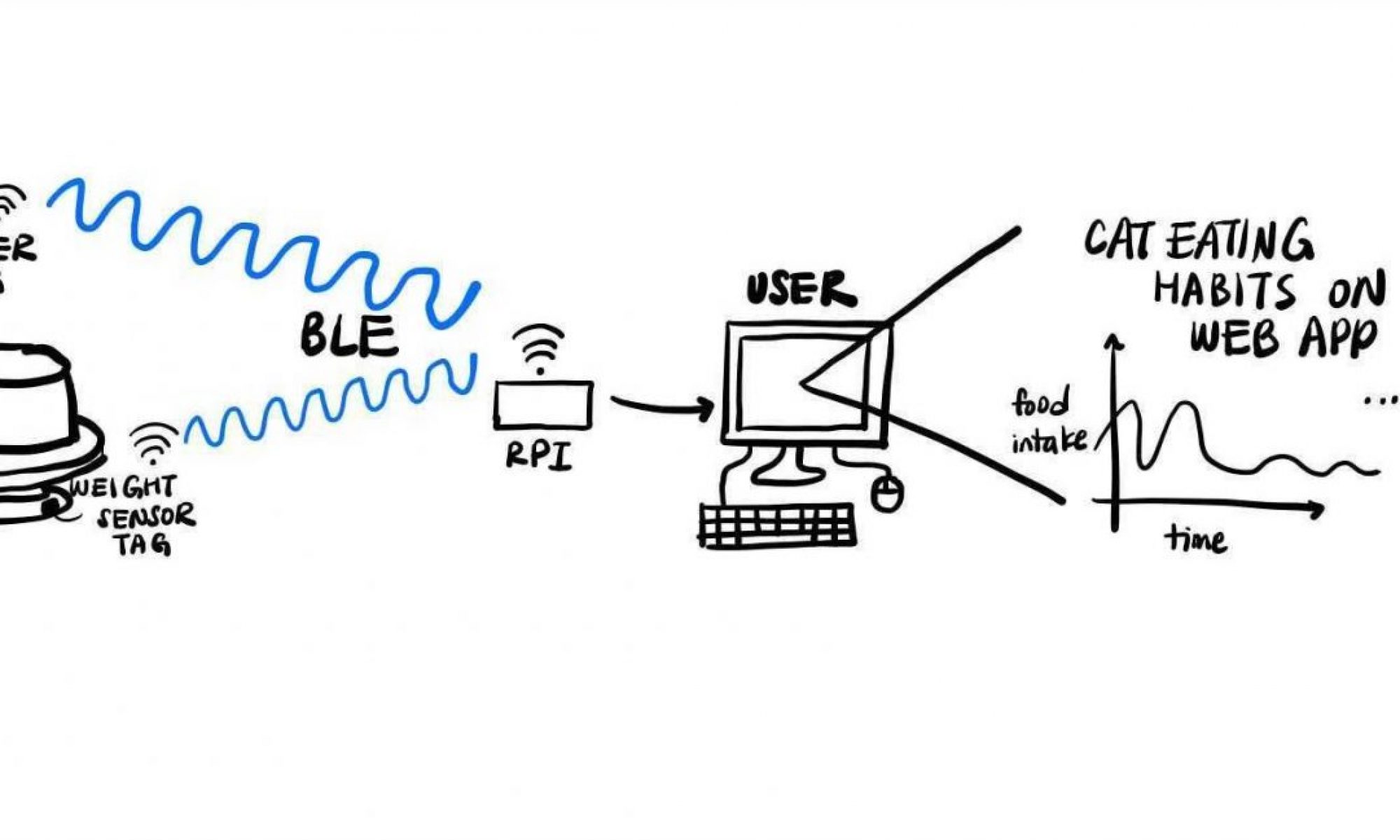

This week finally saw the completion of the full Tag to Hub pipeline. I mainly worked on the firmware required to make the DA14531 board report load cell values as a characteristic (a value sent through the bluetooth protocol to the rpi hub). I also developed the load cell weigh sensing to save values only if they surpassed a preset threshold. Next steps are to run a hardware timer that will report timestamps of when new weight values are added to the array of values – these represent individual “eating events” which the system will count and check for consistency.

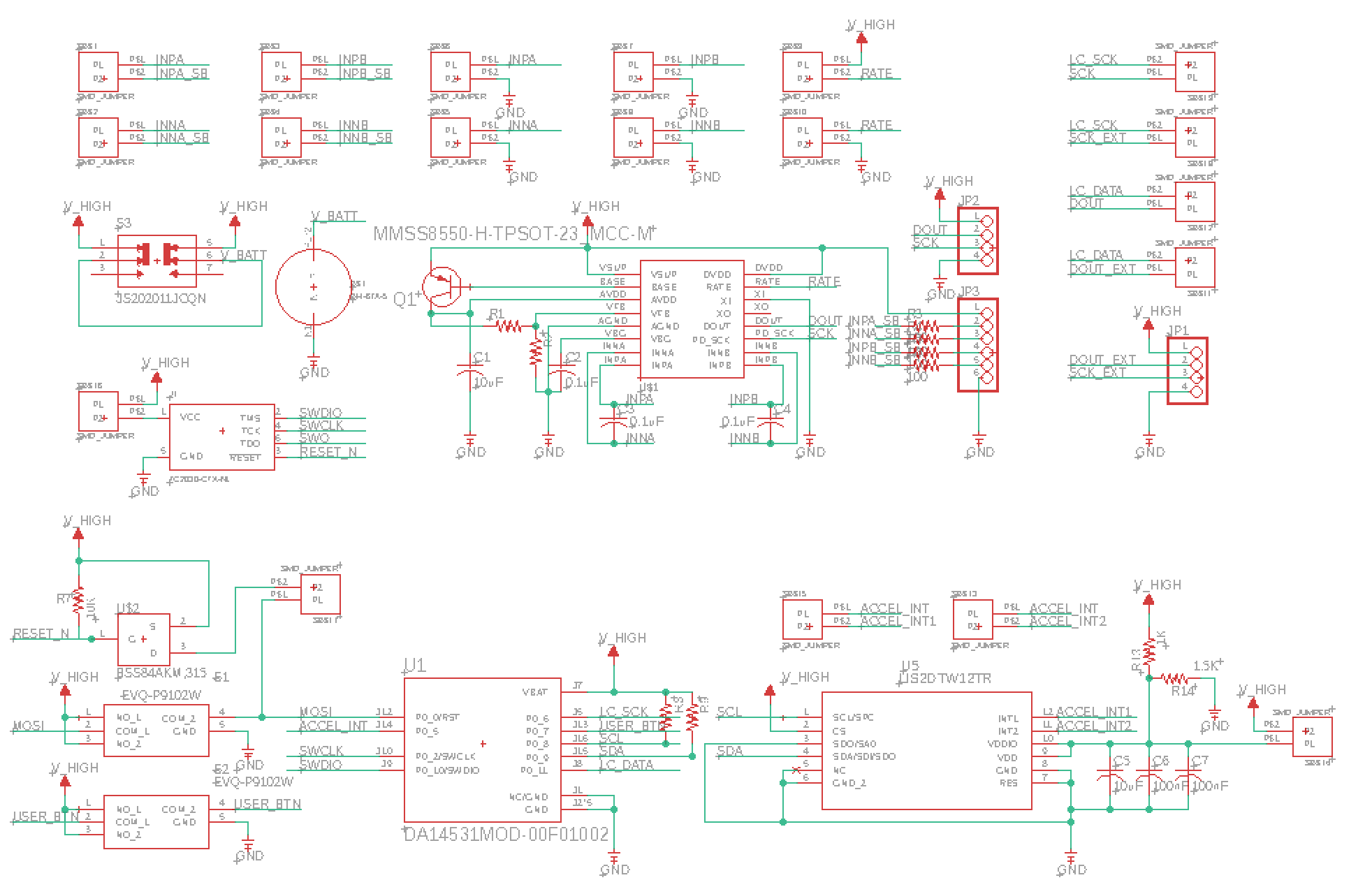

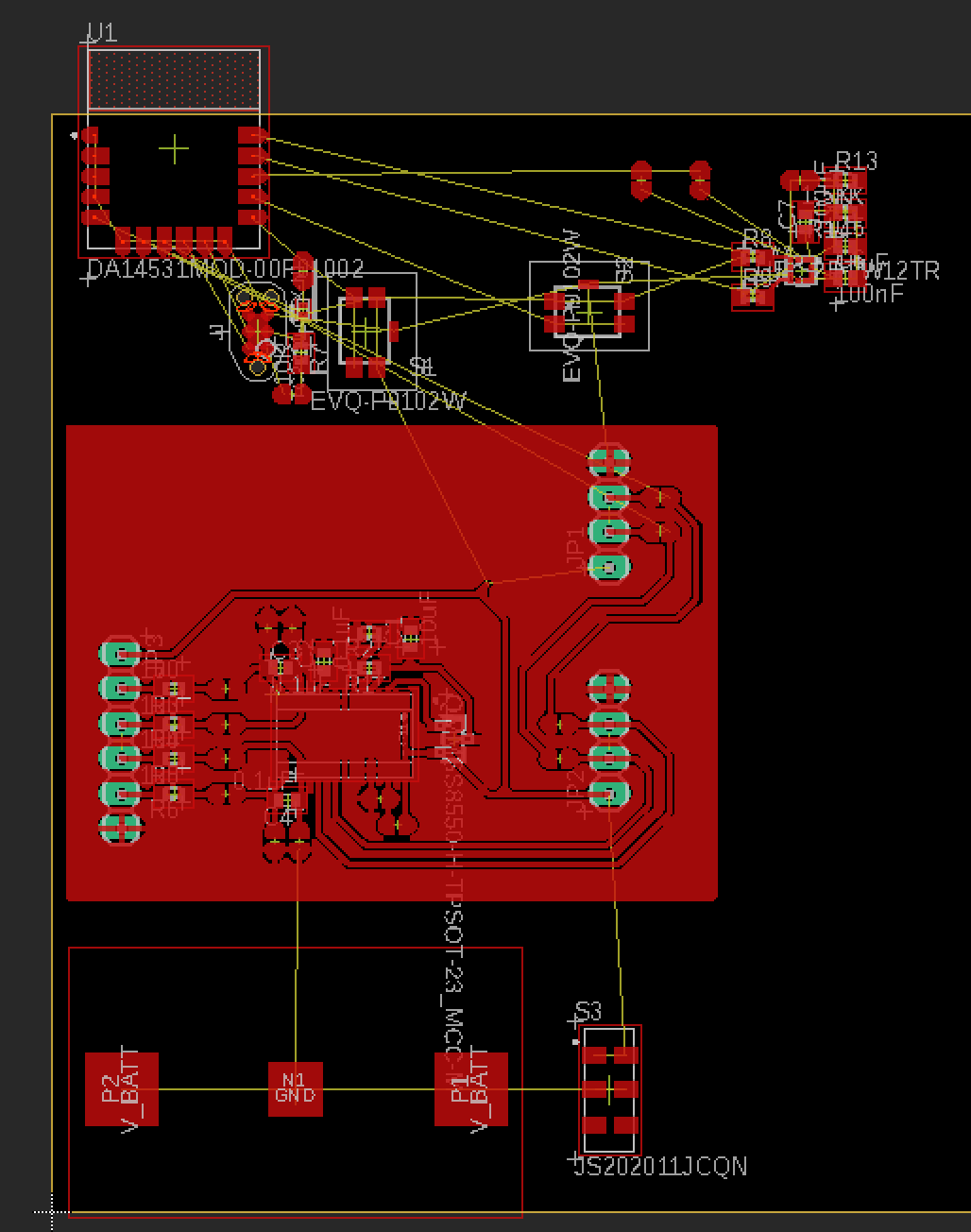

Finally, I re-designed our pcb’s based around the now-available DA14531 Bluetooth module ( basically a small package consisting of the DA14531 chip, a 1 MB SPI Flash, and an antenna with a pre-made CLC filter). The schematics are fully finished and the layout is “near-done” (as in: I expected to etch it out today but it’ll have to wait until tomorrow).  Making PCB’s in-house means they have to be CNC milled – i.e. they can only be single-layer boards. Not having multiple layer to route through definitely adds to the challenge of creating a complex, multi-component design, but I’m managing it.

Making PCB’s in-house means they have to be CNC milled – i.e. they can only be single-layer boards. Not having multiple layer to route through definitely adds to the challenge of creating a complex, multi-component design, but I’m managing it.

I expect to have a functional pcb in my hands tomorrow (Sunday).