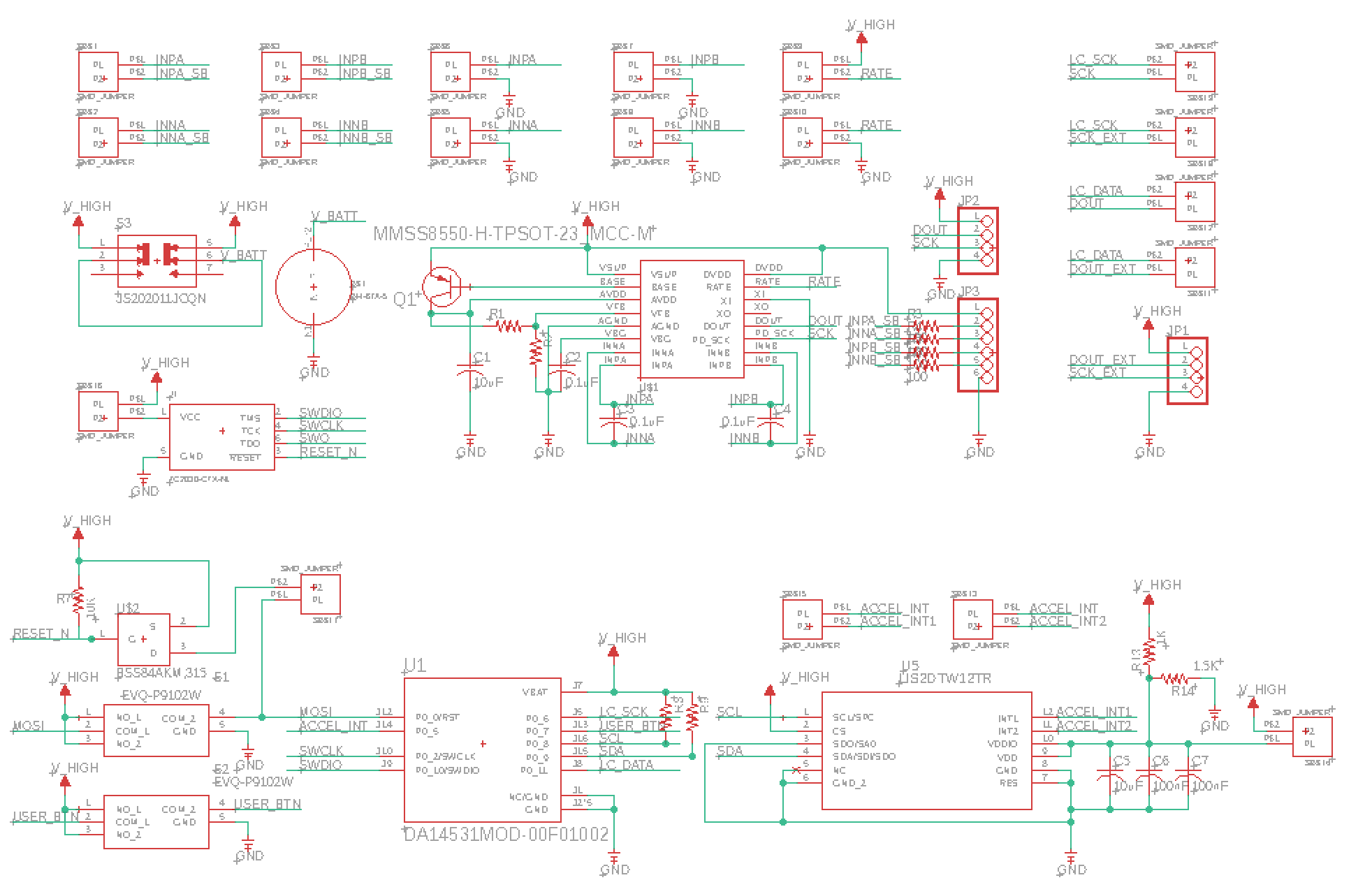

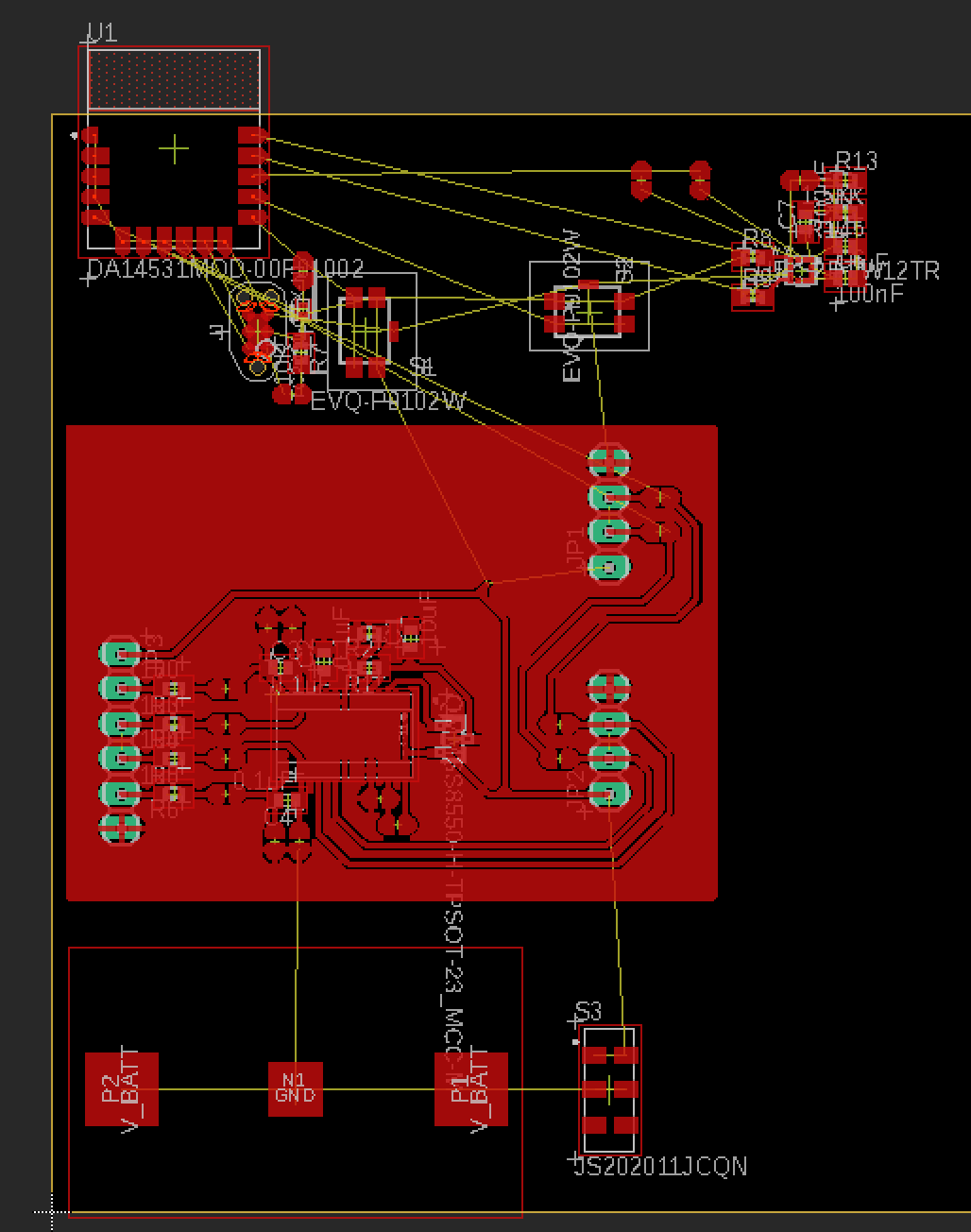

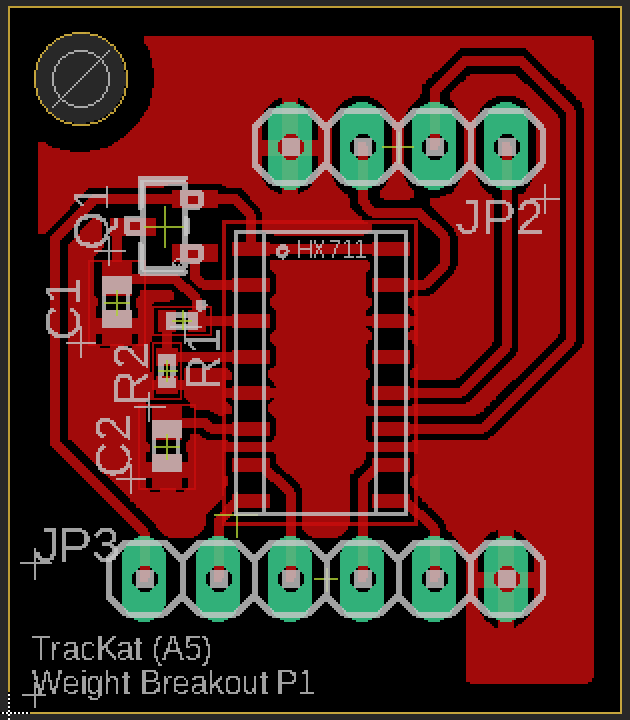

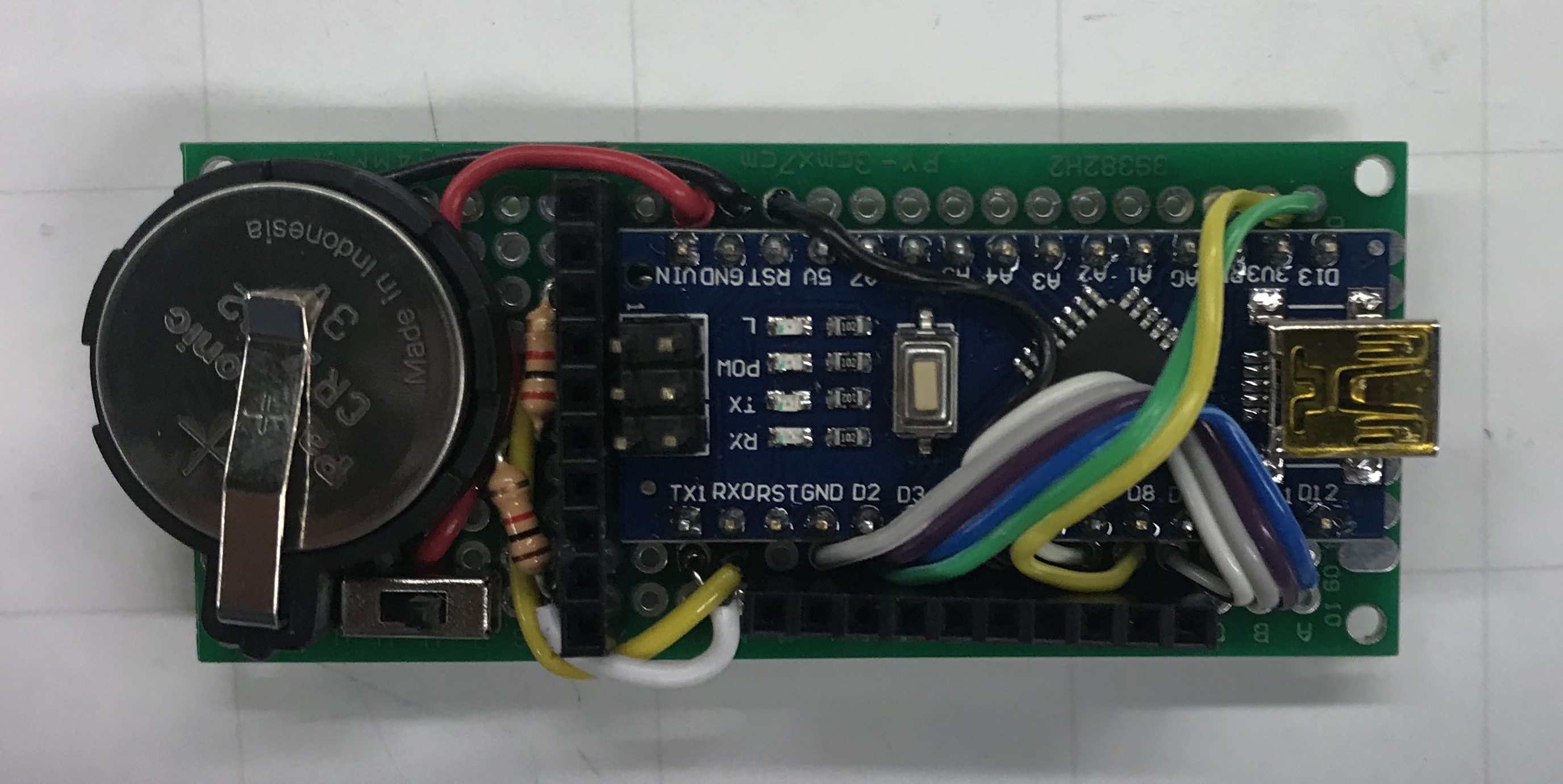

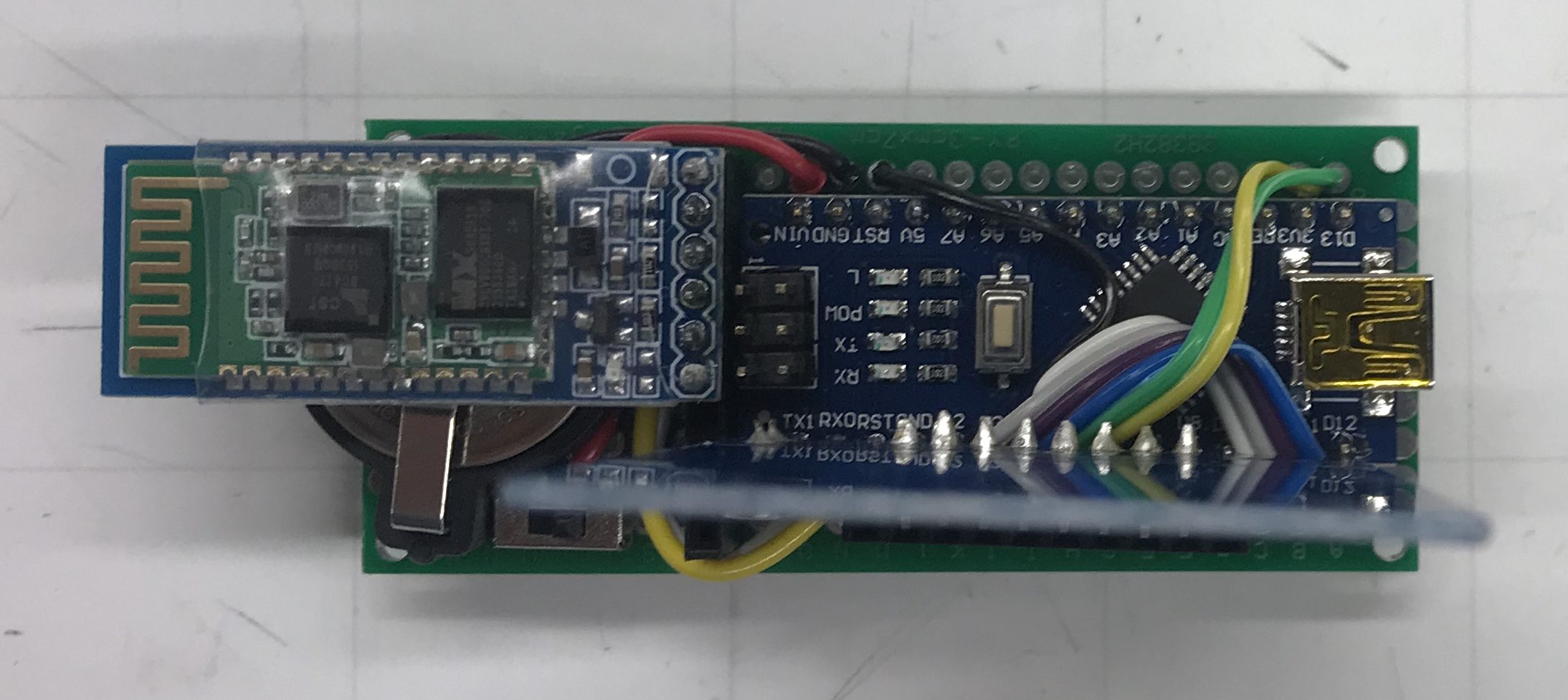

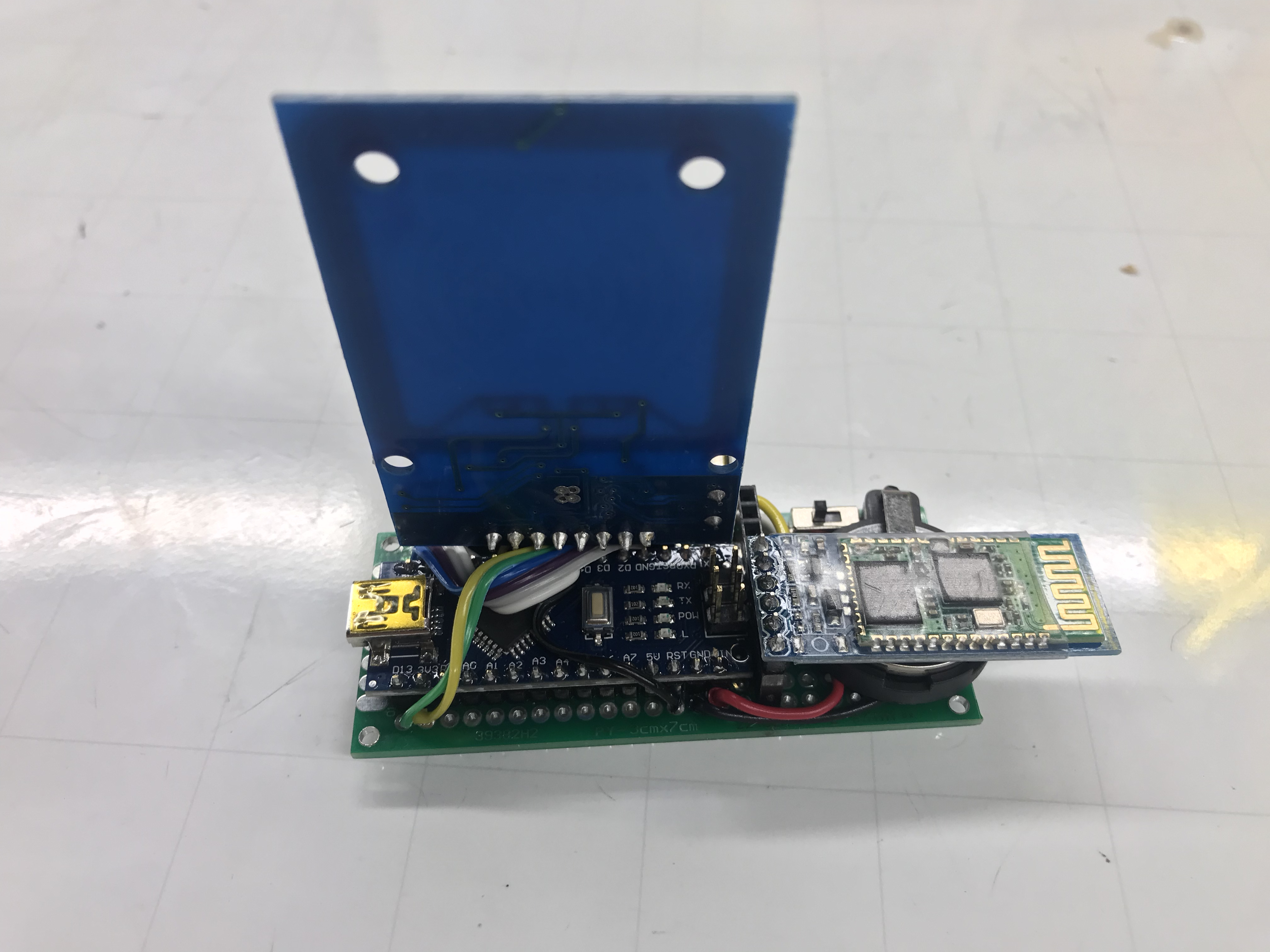

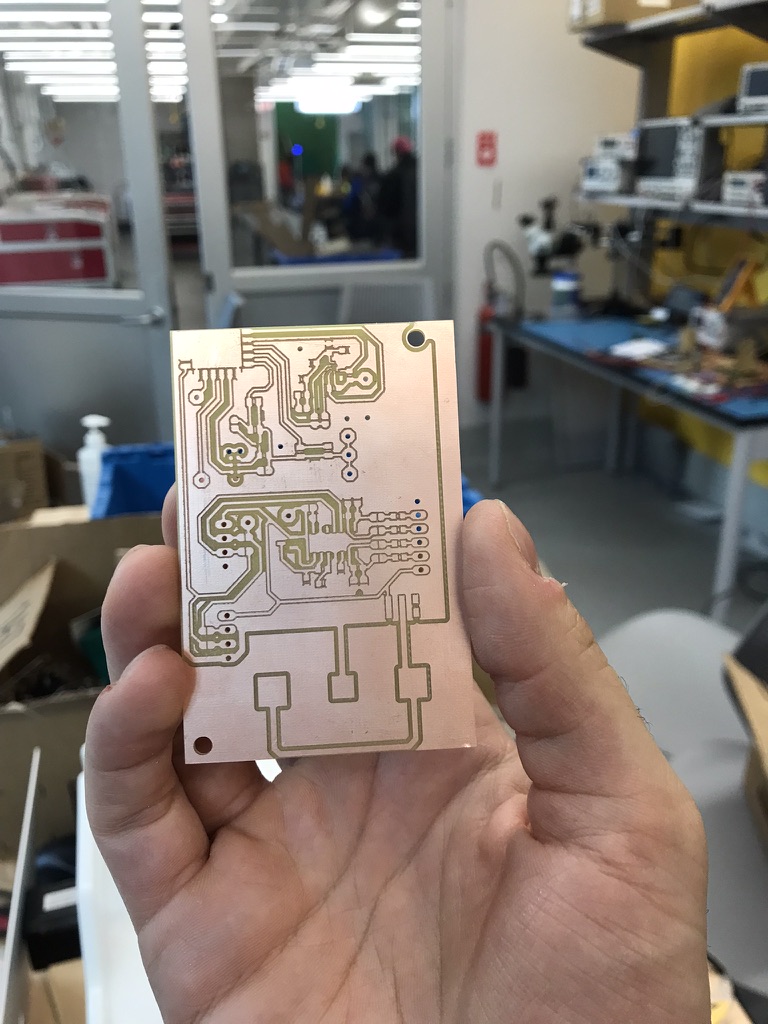

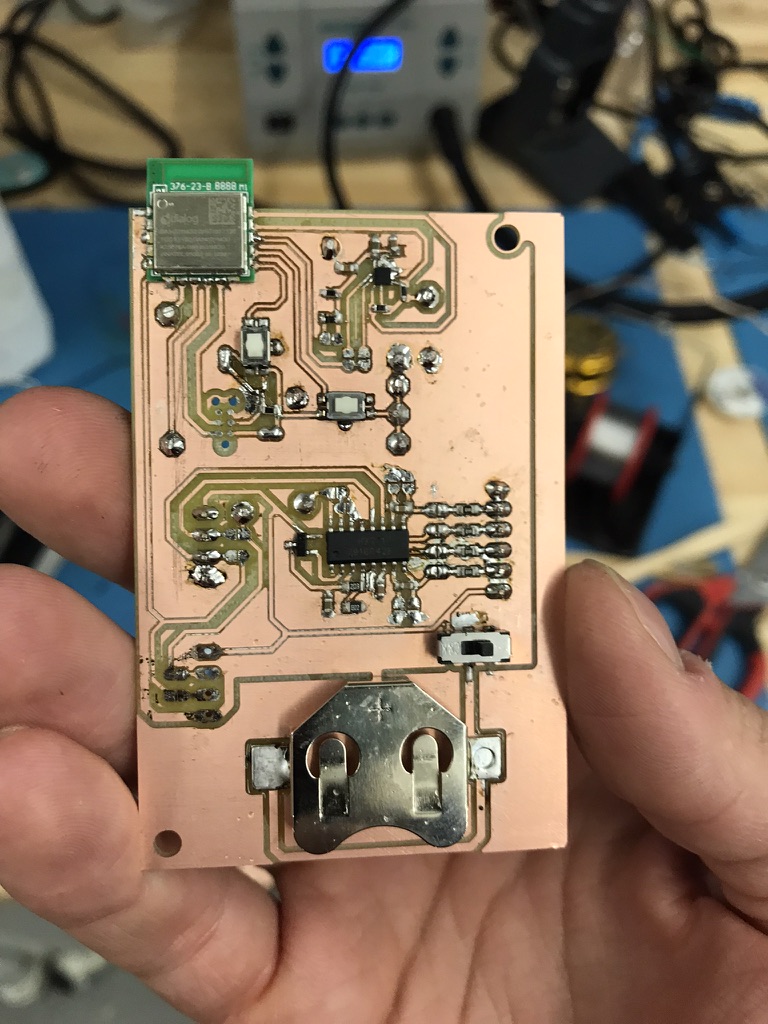

The past two weeks saw major development milestones reached and passed. First and foremost, I finally got the Weight Tag pcb etched and populated!

The tag runs our firmware and is powered from a single CR2032 coin cell battery.

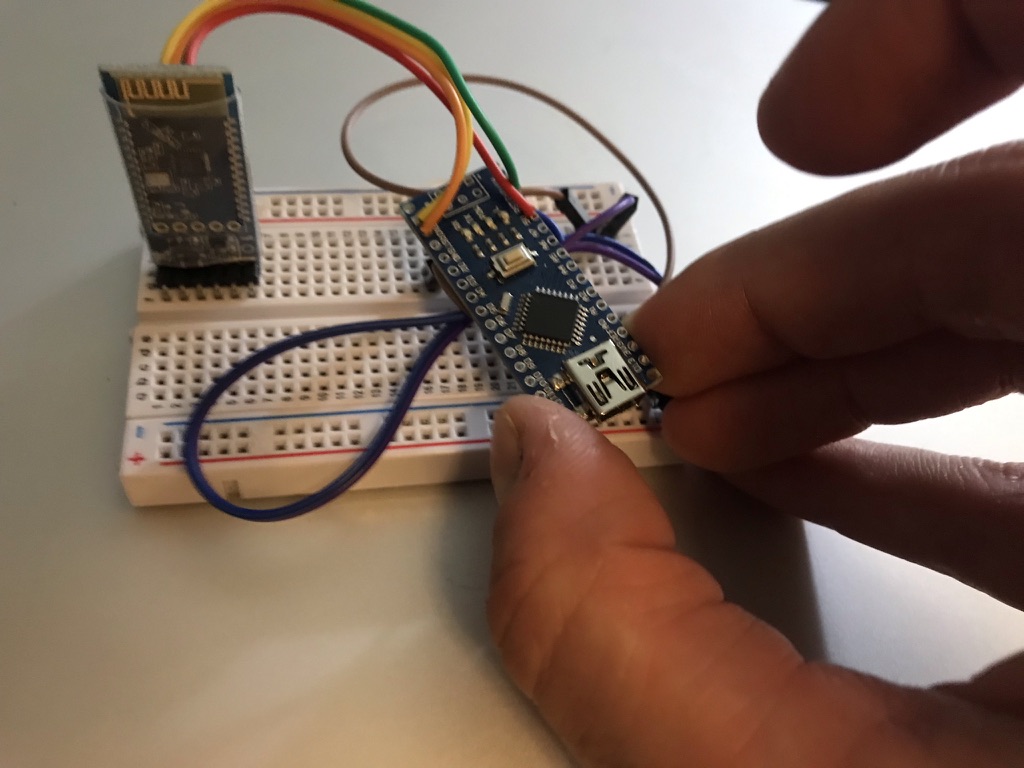

I went back home to New Jersey for Thanksgiving but brought along plenty to work on…it got a bit messy:

While on break, I primarily worked on the RFID firmware, the Weight Tag hardware (populating a second board), and conducting live tests for our final presentation slides.

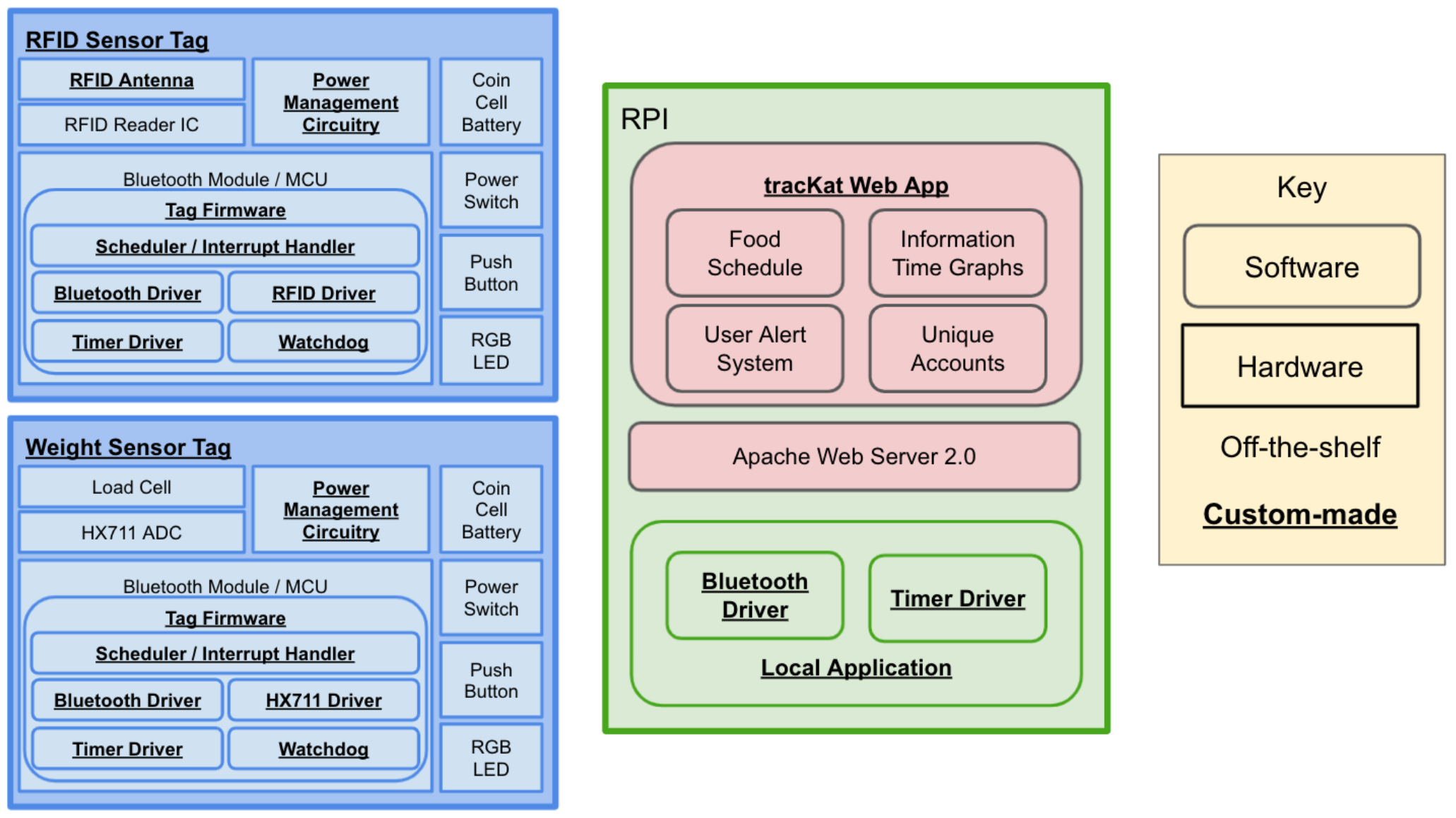

After coming back from break, I helped wrap up the final report. Specifically, I wrote the Solution Approach (slide 2), Hardware (slide 3), Live Testing (slide 7), Results (slides 8 and 9), Design Trade-Offs (Slide 10), and Lessons Learned (Slide 11). I also helped on the Project Management (slide 12) and Public Demo (slide 6).

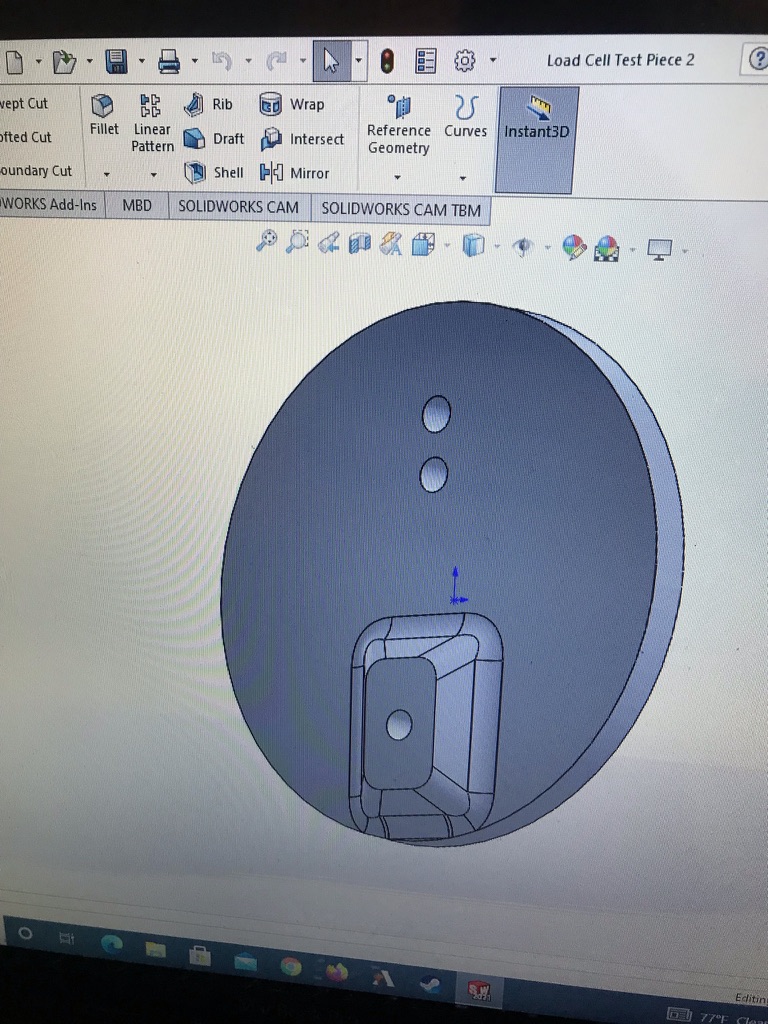

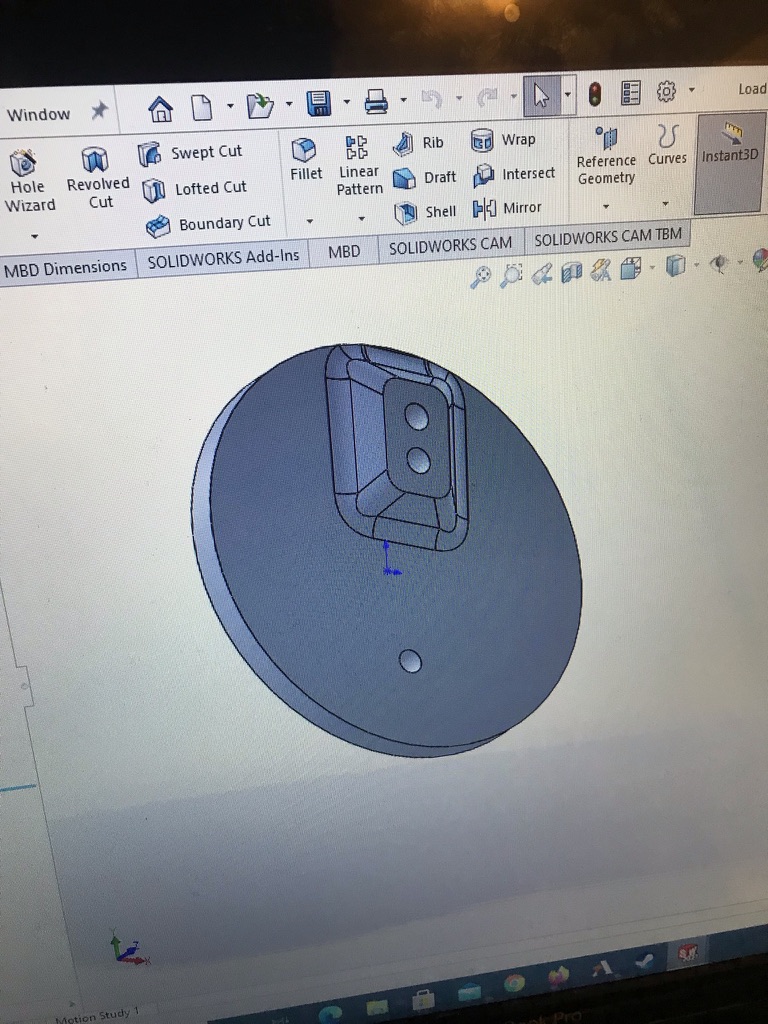

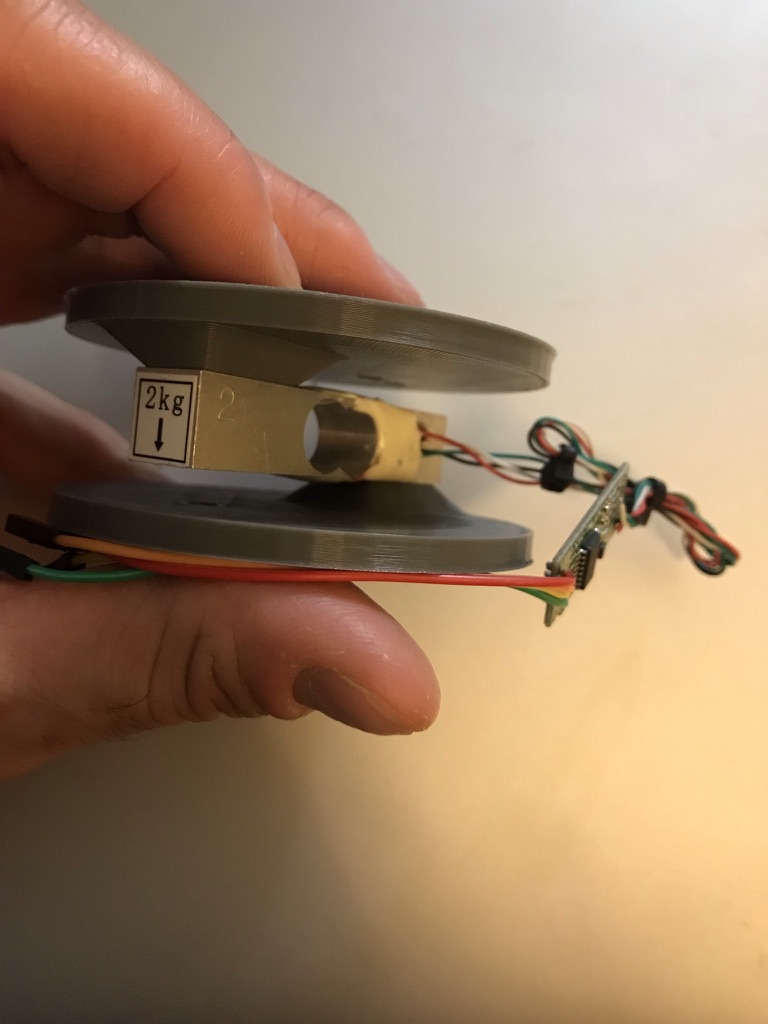

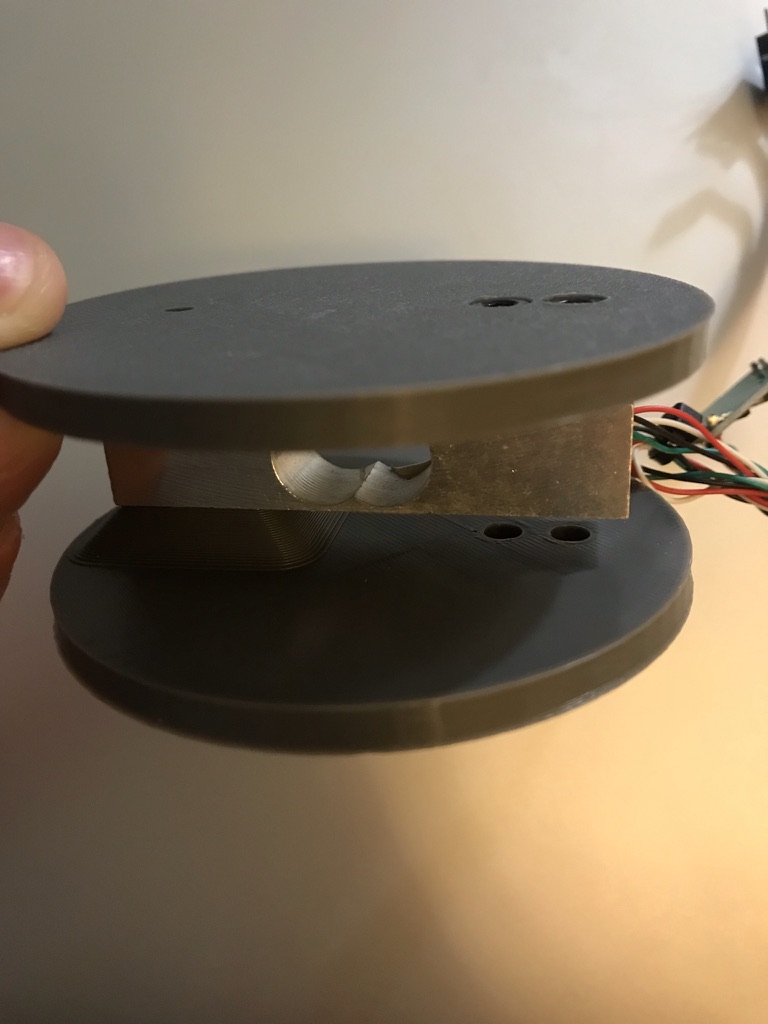

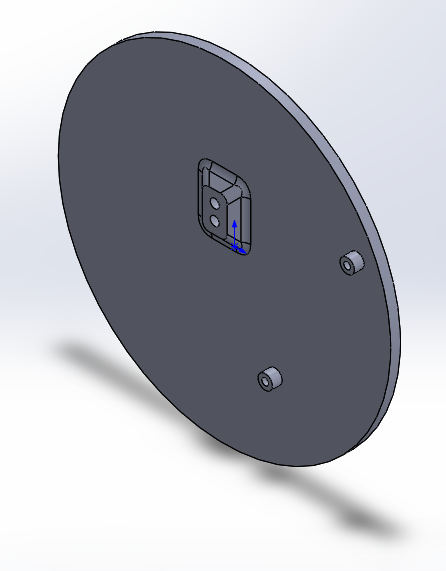

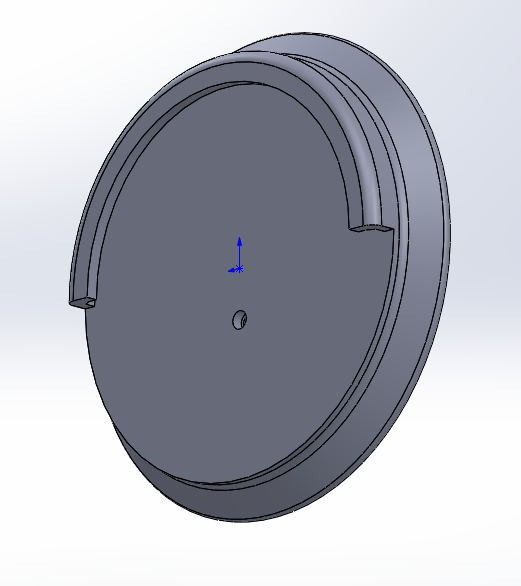

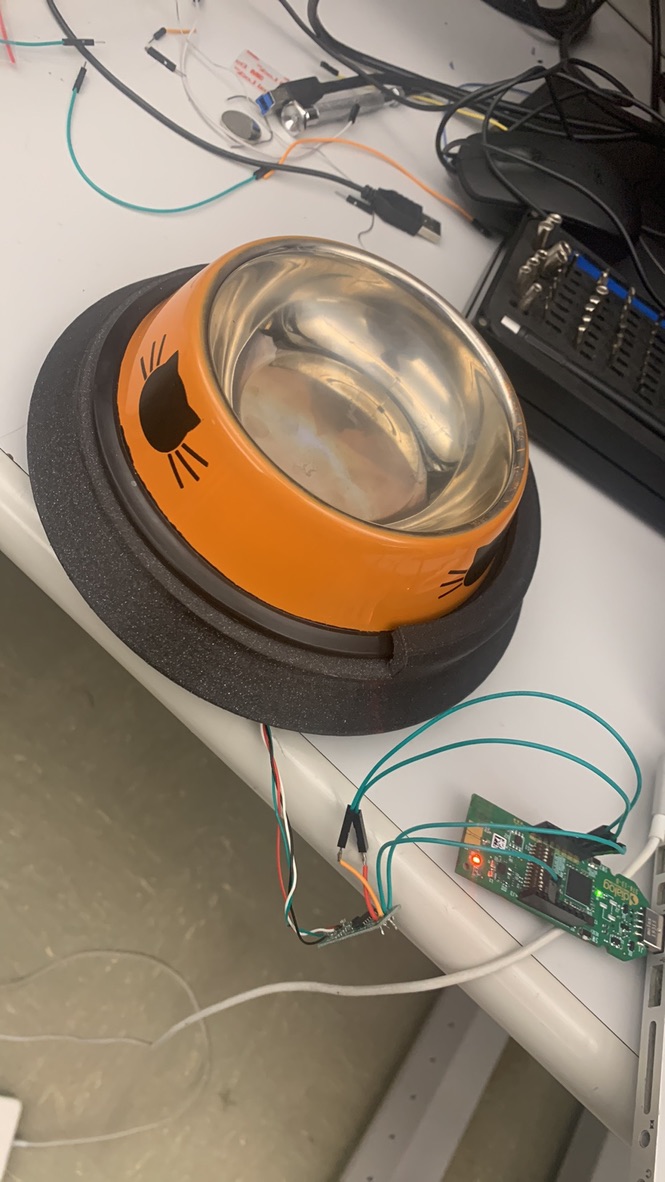

After our final presentation, I took some time to design the enclosure for our weight tag from scratch and printed it out (bottom piece is printed but currently locked in Roboclub :P):

The enclosure’s top features a lip to snuggly secure the food bowl and a skirt to push any water or kibble that falls out of the bowl away from the electronics housed underneath. The bottom plate has mounting holes for our custom weight tag offset from the base to add further protection against water damage.

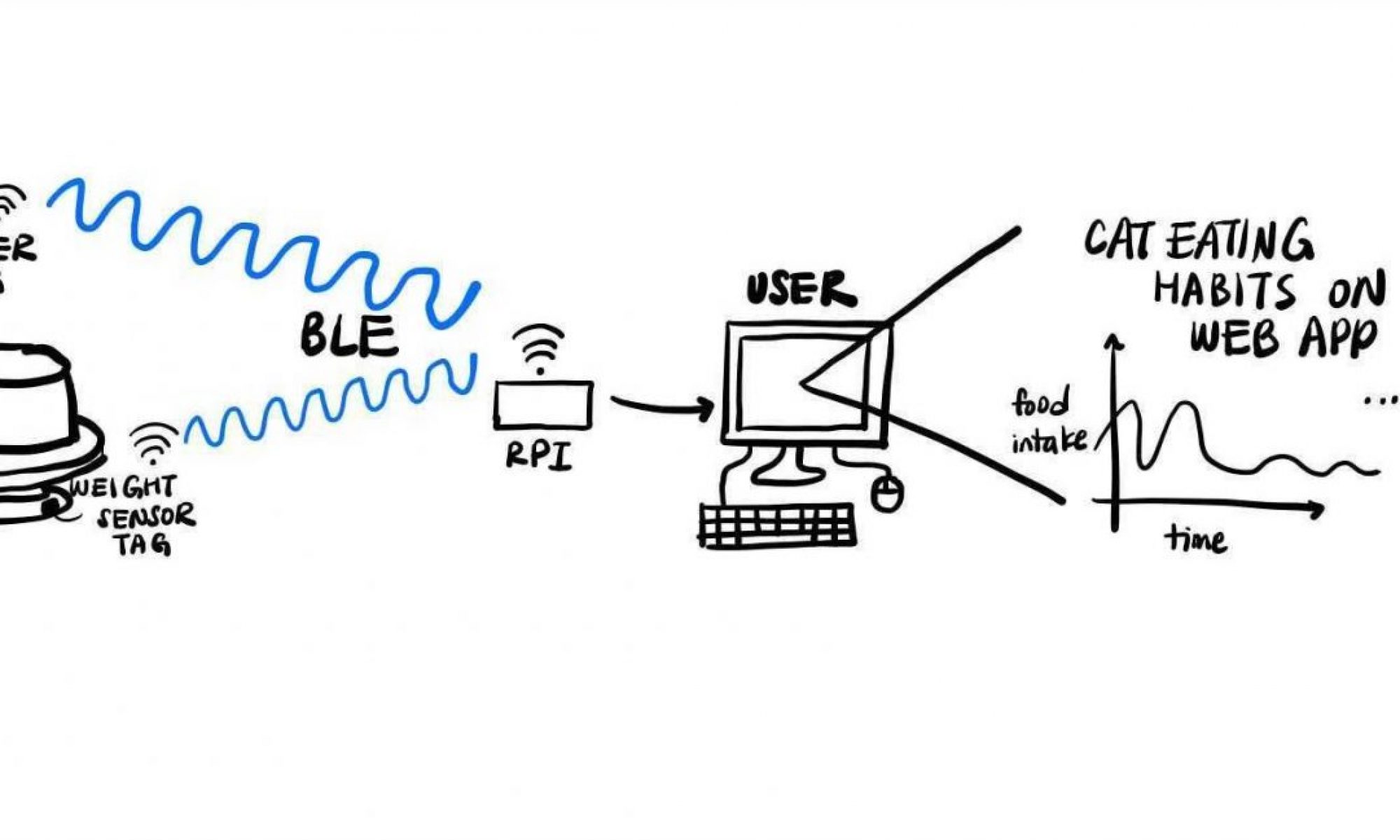

To wrap up the week, I debugged and fixed some issues with the characteristic values from the tags not being seen by the RPI over BLE.

With the weight tag just about fully finished, my goals for next week are to wrap up RFID and prepare for the final demo. Time is tight, but at this point I am confident we’ll have a solid project to show off.