This week mostly had me tied up by a pretty tight crunch at work, but I still got through most of the goals set out for this week. These were mainly to get the demo hardware working as well as finalizing the BLE module trade study and selection. I also worked with MeeDm and Tarush on the Design Proposal presentation.

One of the most unexpected hurdles in choosing the BLE module ended up being totally unrelated to technical trade-offs: logistics. As it turns out, the world is experiencing a really bad semiconductor shortage, and the supply chain for ic’s and mcu’s has been left in a rough state as a result. Almost all the options I considered ended up having to be scrapped due to either a development board or module not being available – in some case’s the ic itself was out of stock with lead times ranging from 18-52 weeks!

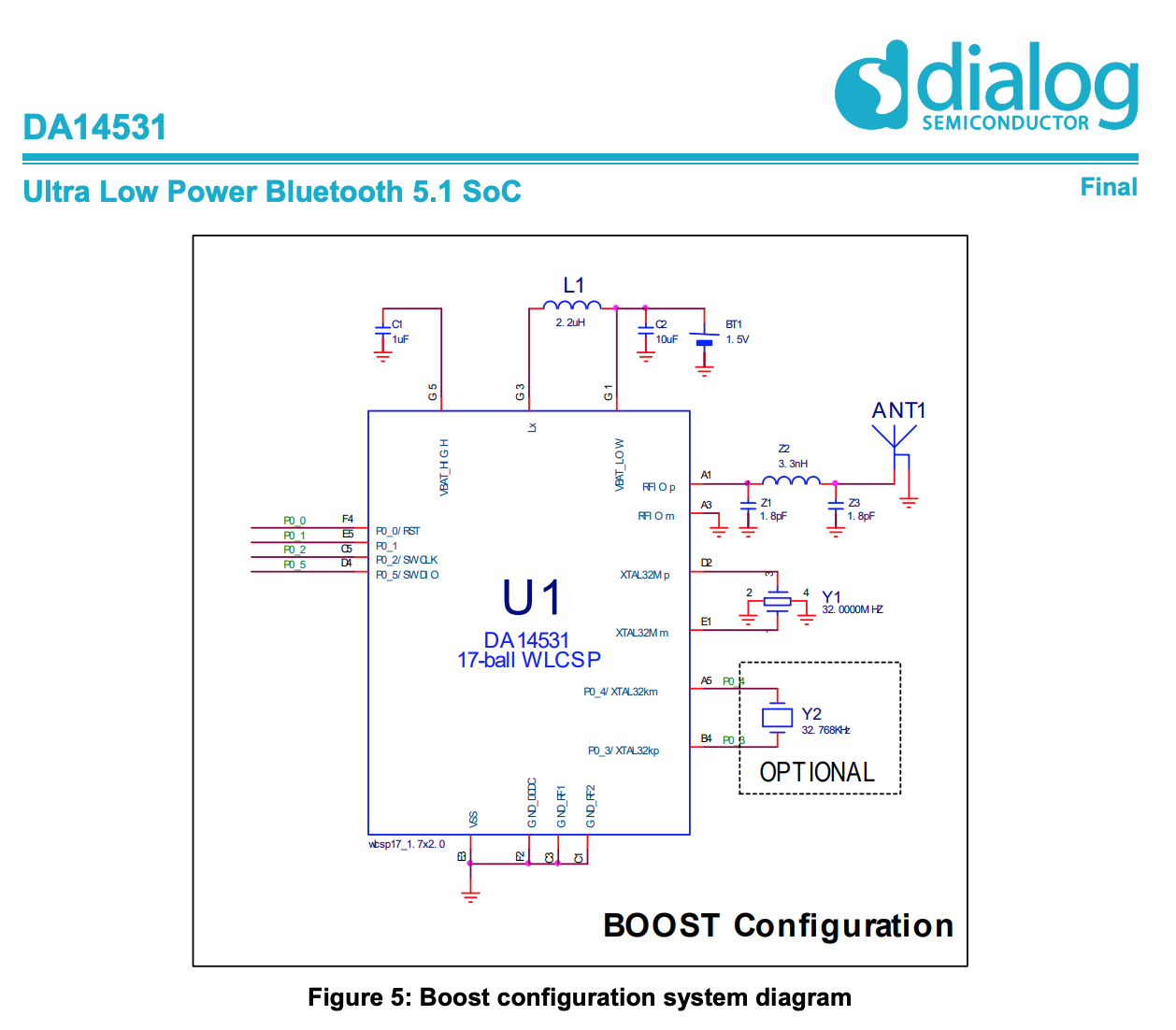

In the end I settled on the DA14531 BLE module. The primary points I considered were power consumption, ease of development/implementation, and supply chain; the DA14531 knocked each category out of the park. This IC features an ARM Cortex-M0+ processor and achieves absolutely top-of-the-line power consumption specs of under 22µA/MHz clock rate and 240nA hibernation mode. Dialog Semiconductor provides ample documentation and has an active forum – critical to ease of development. Finally, the IC and its accompanying evaluation boards are in stock and readily available from a number of distributors, including DigiKey. With the order placed, my focus will now shift towards getting the prototypical schematic and layout finished for the BLE tags.

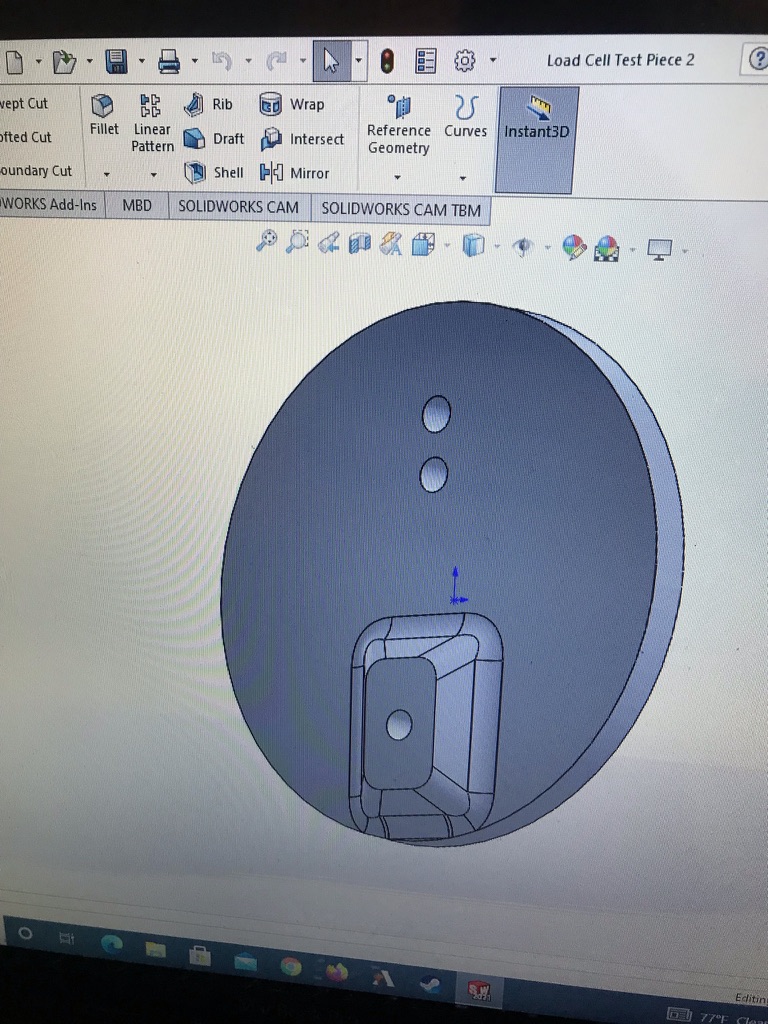

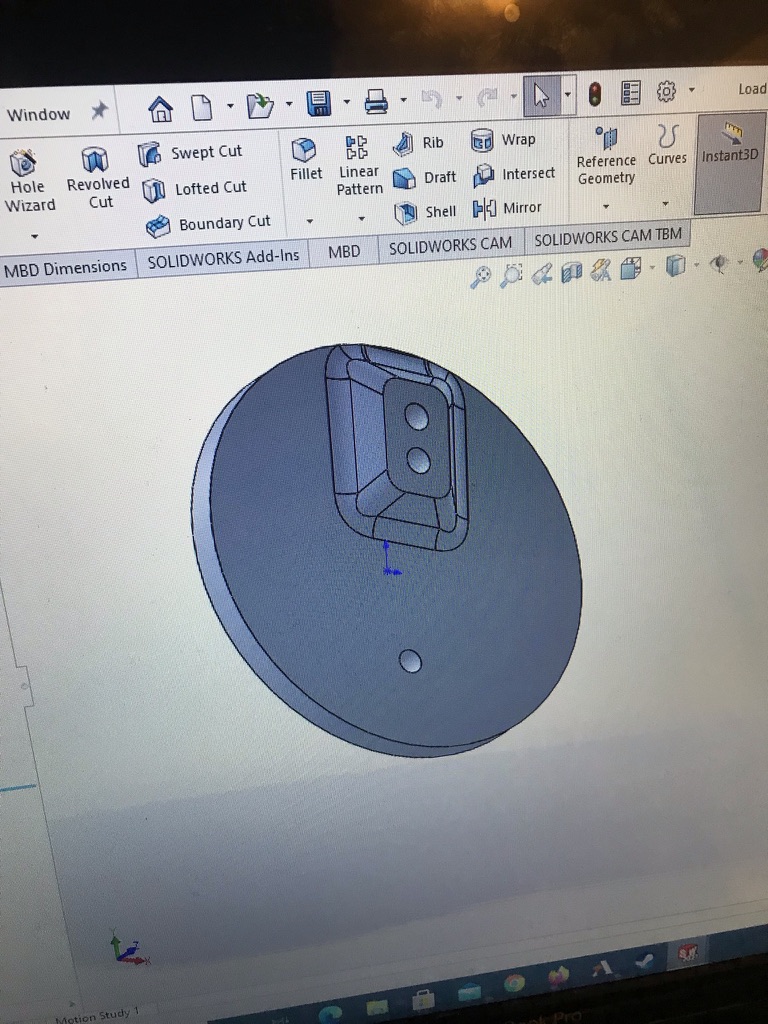

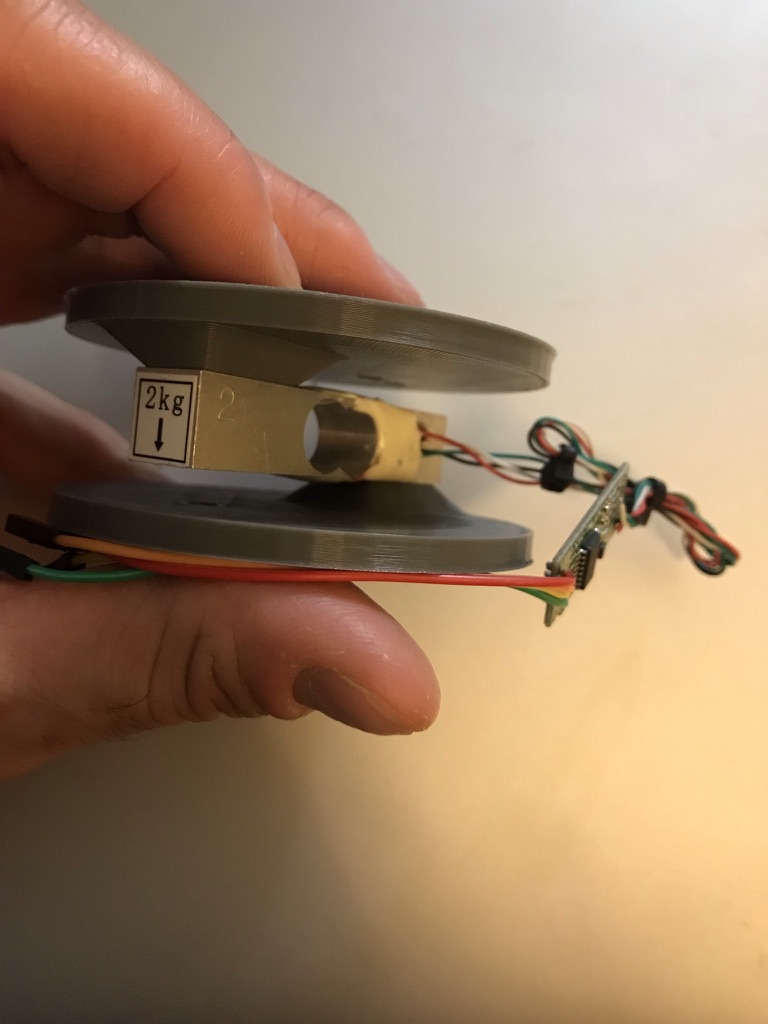

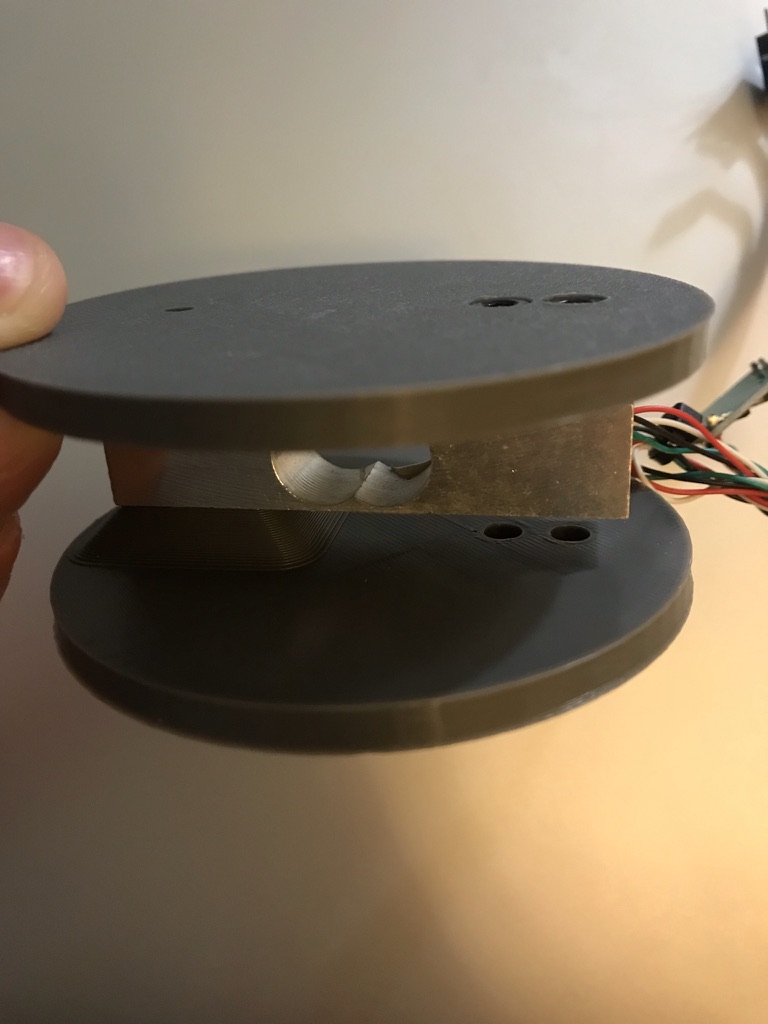

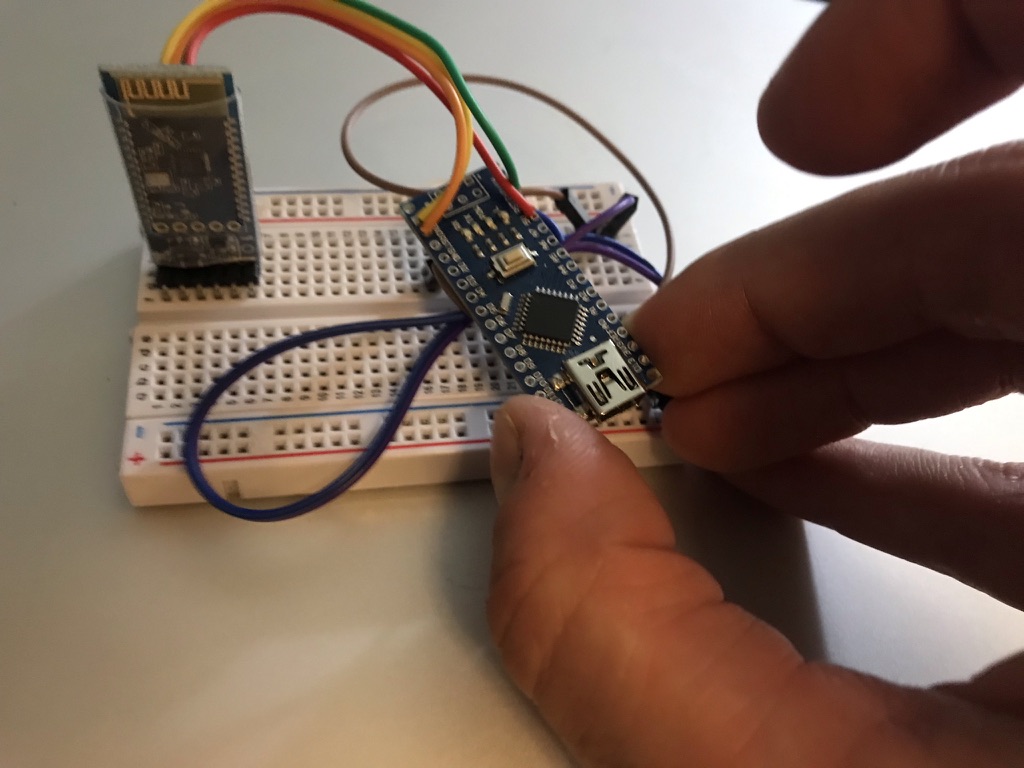

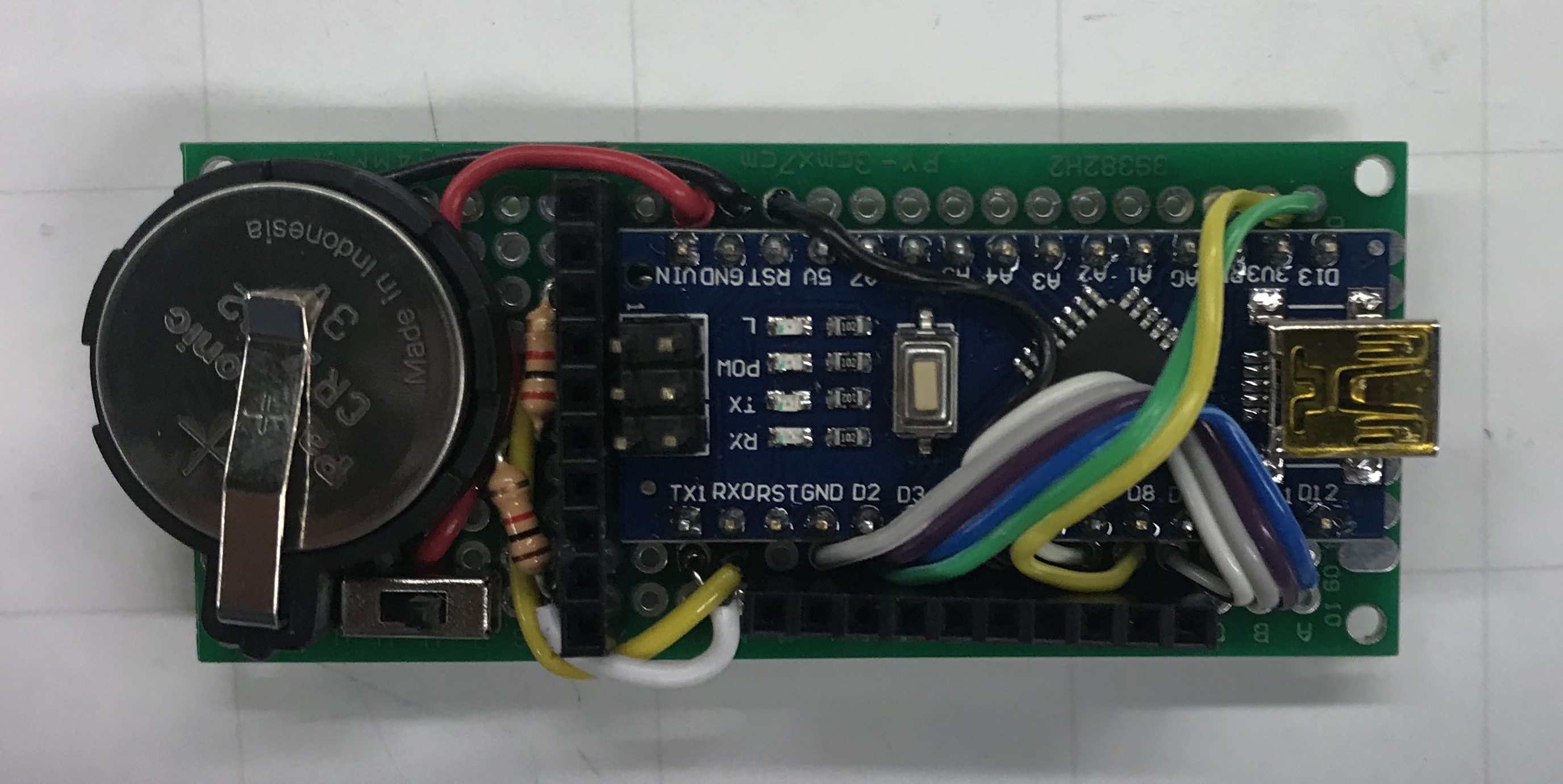

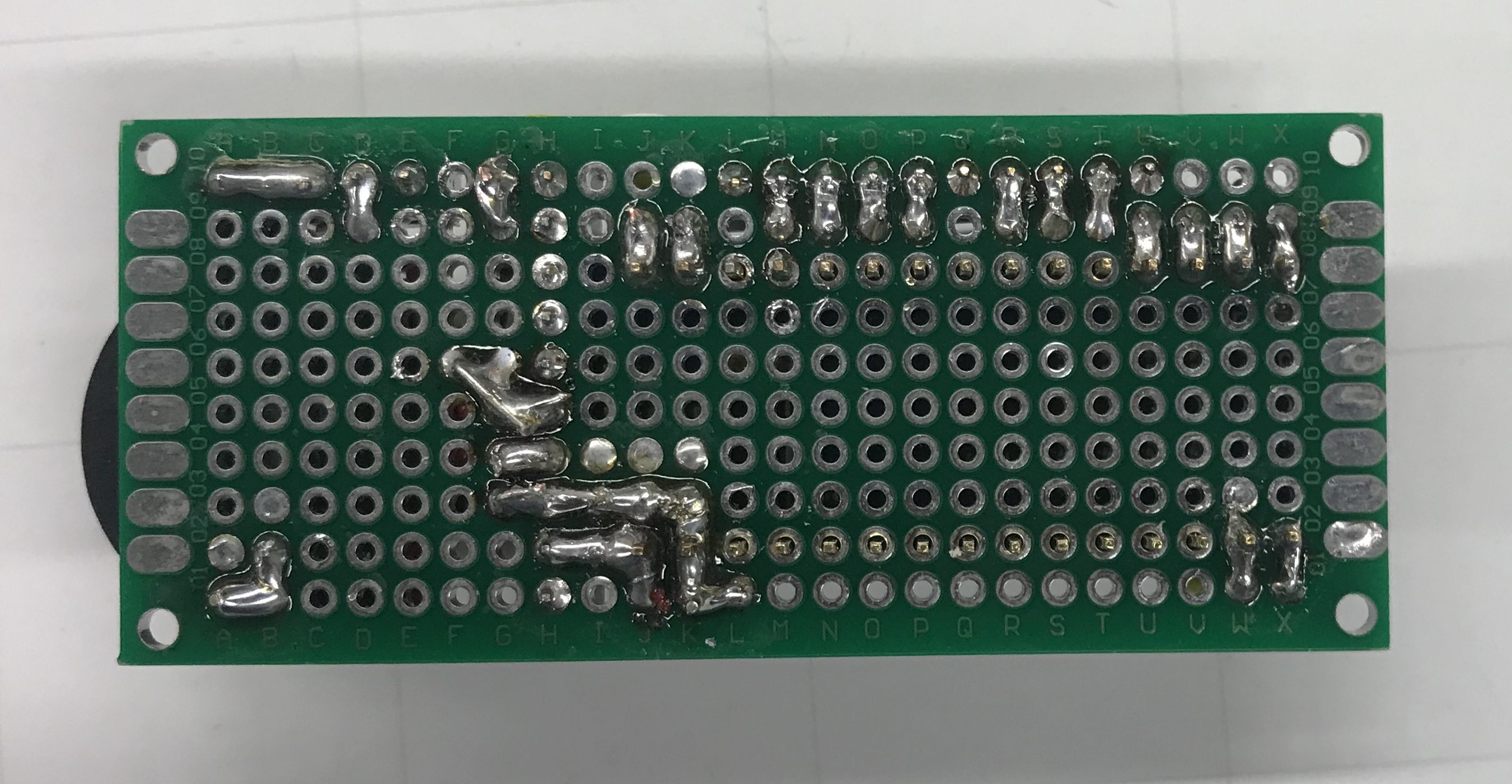

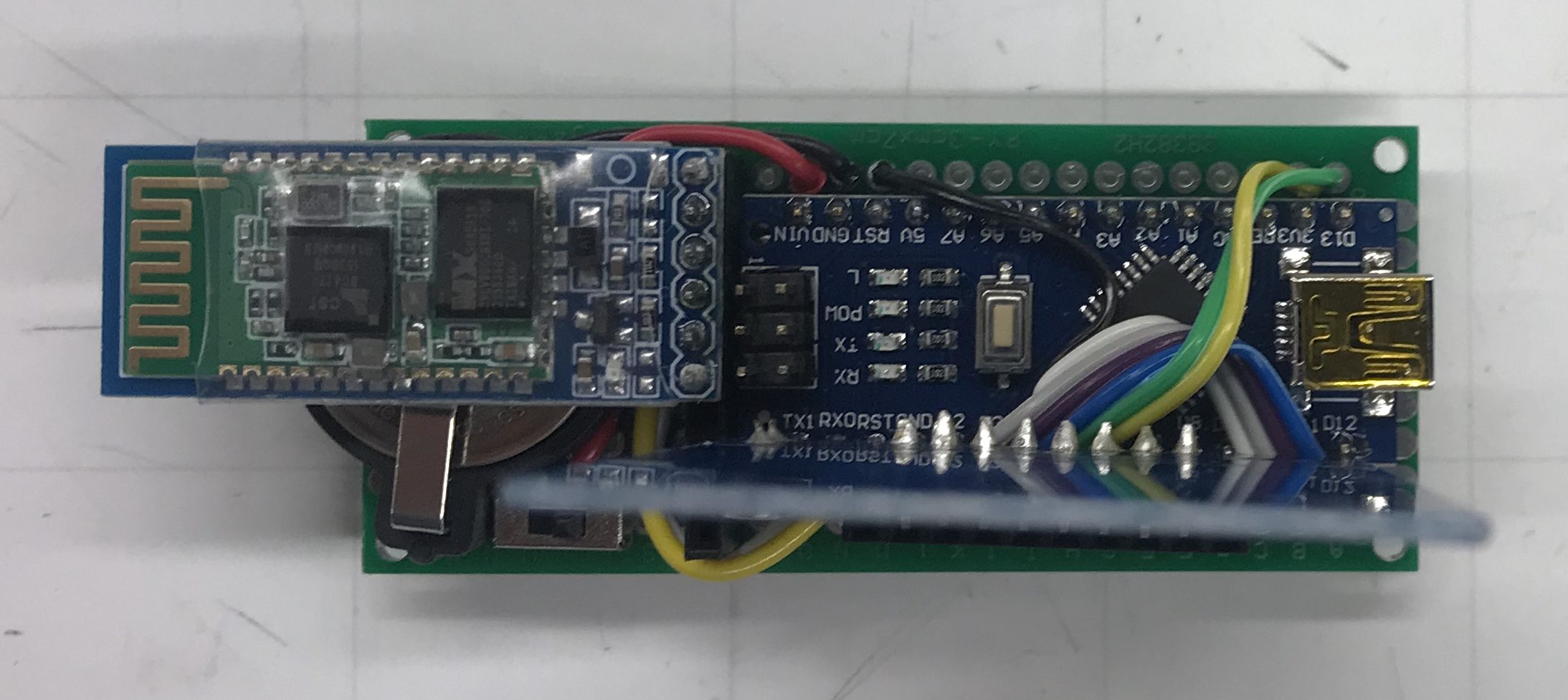

Speaking of tags, I also worked on the Arduino-based demo hardware and completed assembly of the RFID bluetooth tag:

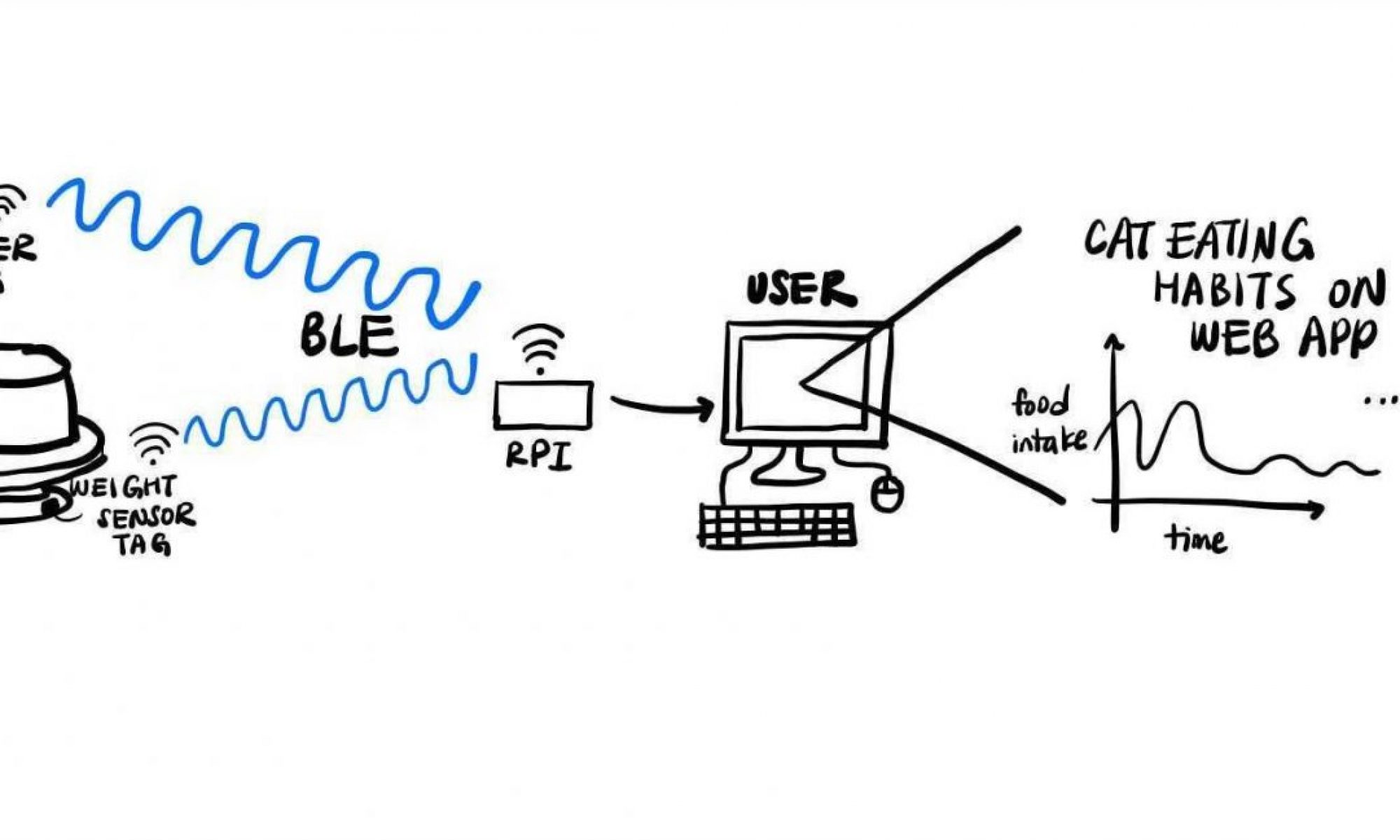

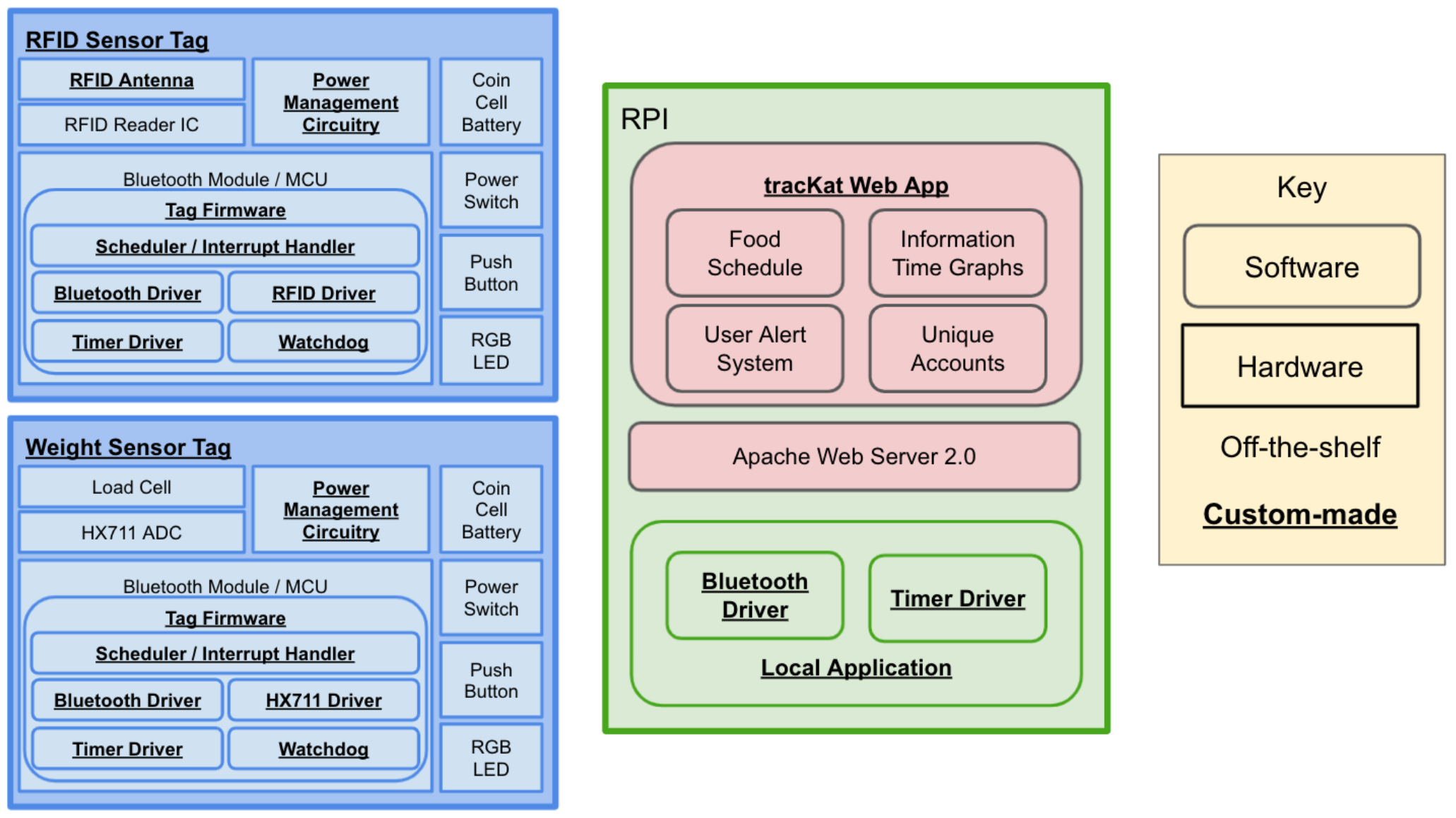

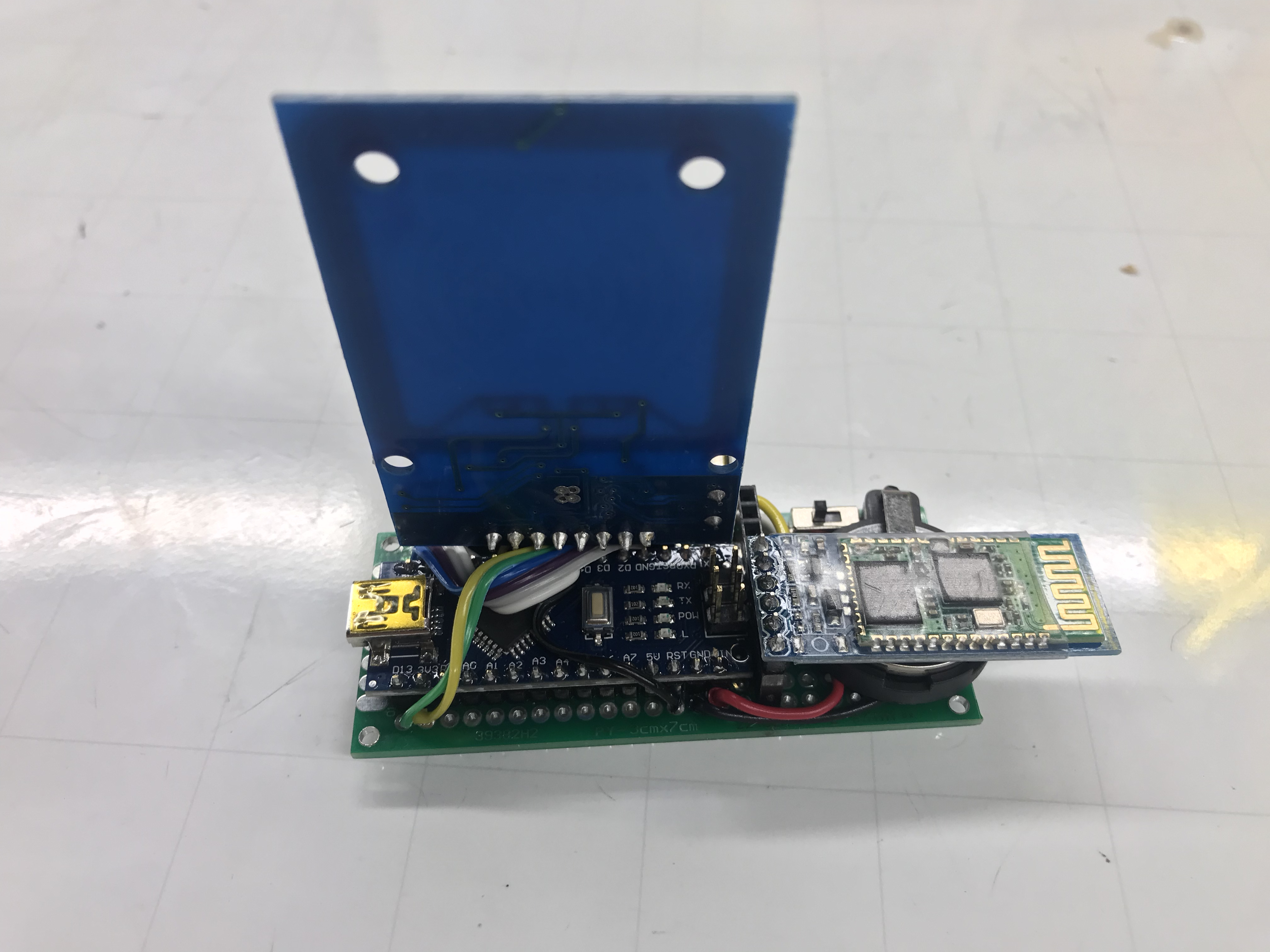

The tag features a coin cell holder, headers for an HC-05 Bluetooth module and RC-522 RFID reader, and power switch. It’s quick, it’s dirty, and it works. Along with the load cell based weight sensing tag, this RFID tag will allow the team to develop and test the full project pipeline on real hardware without waiting for the actual BLE tag pcb’s to be spun up. Next week I’ll wrap up the demo hardware by putting it in a nice, custom-made enclosure. I’ll work with MeeDm to get it connected to the RPI and I’ll work with Tarush to have the web-app display communications between the demo hardware and the RPI hub.

As I learned the hard way this week, a new risk to consider is time commitment at my job. Going forward I’ll have to actively temper my responsibilities there with my work here.