This week we made a lot of progress on the software aspects of the project. Rashmi and Ishaan worked on integrating the computer vision algorithm, the iRobot Create 2 code, and the Intel RealSense Depth camera’s code into one piece of software. When connecting the Real Sense camera and Create 2 robot to a laptop, we were able to successfully combine all 3 parts of the software. Depending on the location of the tennis ball in the Realsense camera’s field of view, the Create 2 robot would turn to try and cause the ball to be in the center of the camera’s field of view. This is what we want so that the ball will hit the center of the robot and be collected by the arms that we are working on building.

However, we still need to work on running this integrated software on the Jetson Nano which will ultimately control everything. When trying to install everything on the Jetson Nano, we ran into the issue of the Intel RealSense depth camera’s Python library not being able to be installed using pip on the Jetson Nano. This is because installing the library with pip wasn’t supported on the Jetson Nano’s architecture. This was an unplanned setback, but we plan on fixing it this week by building the Realsense library from source which should not be too difficult.

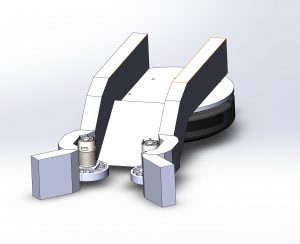

In terms of building the robot, we had a few setbacks this week. We as a team spent most of the day measuring and cutting the word so that we can assemble the robot. However, we had tried to make cuts in wood at 45 degree angles so that we could connect two pieces of wood at a 90 degree angle. However, we realized that drilling into and connecting 2 pieces of wood that were at an angle was very difficult, especially since our cuts weren’t perfect. To fix this, we decided to make flat cuts in the wood and just connect different pieces face to face which would eliminate the issue of imperfect cuts and make it much easier to connect the pieces of wood.

Schedule Update:

Currently, we are on schedule on the software side of the project, but slightly behind on the hardware part. To make up for this, we plan on spending more time in the Makerspace this coming week to get our wood cut and start connecting the pieces together to make the structure that will support the tennis ball collection system. Then we can also add the motor control software to our code and test if all the software and hardware is working together.