[Alisha] Status Update 11.30.19

I’ve been in lab nearly every day this week to get us demo-ready by Monday. It’s been quiet but productive over the holiday.

[UI]

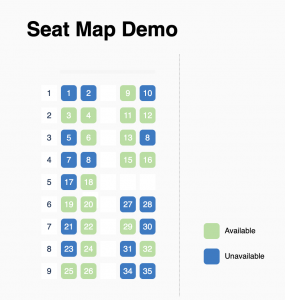

From the perspective of the UI, I’ve separated Hunt Library into several zones, with one sensor hub per zone and each zone containing up to 12 carrels. Our demo will have 3 carrels representing 2 zones, with 1 desk in one zone and 2 desks in the other. I cleaned up the UI to show the 3rd-floor map and highlight the available desks (see screenshot below). I have a server running on my machine that aggregates JSON data from each sensor hub’s POST requests and updates the UI map as needed.

[Circuits]

I’ve soldered two sensor hub breadboards for the two zones, and each has a power line, a ground line, 12 PIR sensor I/O pins, and 4 LED drivers to run the Charlieplexed scheme. Each of these wires is soldered on one end to the breadboard and then I attached crimp connector housings to have a female termination at the other end. This is based on our TAs suggestion to make our connections easy to plug/unplug for the sake of mobility and ease of demo setup. The LED wire runs up the side of the carrel to the top corner and the PIR sensor bundle (power, ground, signal) runs along the inside edge of the carrel to the underside of the shelf. Currently, the capacitive sheet is connected with alligator clips and wire feeds out the back of the desk.

[soldered system pic]

[System]

I’ve also been working on making sure our timing requirements are being met by our system. Currently, a script on each RPi collects occupancy and capacitive data as such:

- In 2.5 second (adjustable) intervals it polls the PIR and capacitive sensors for desk occupancy data and sends POST requests to the UI with the stats for its zone.

- In 30-second (adjustable) intervals, it updates the LED lighting scheme, which is a loop across all lit LEDs running quickly enough such that the human eye cannot detect a jump.

Built a stand-alone system: a single fully wired carrel with the mounted PIR sensor, capacitive sheet, LED, and an RPi sensor hub with a Pi Cap. No solderless breadboards or monitors attached! 🙂

[wired carrel pic]

[Risks]

I’ve resolved all of my pending work over the last 10 days, except for the capacitive sheets, which Charlotte is primarily in charge of. Hopefully, when she returns we’ll be able to fix that element or come up with a different working solution.

Deliverables for next week:

In-Lab Demo – 10/2:

- Assemble full demo setup with three carrels

- Test and adjust capacitive sheets until reliable

Classwork:

- Final presentation – 10/4

- Final design document – 10/8

Public Demo – 10/10:

- Debug RPi Zero connectivity issues in order to successfully sub out the more expensive RPi 3Bs

- Laser-cut or 3D print our sensor hub casings, sensor wedge mounts, and sensor cones (currently made of foamcore and paper)