[Alisha] Status Update 11.23.19

[Circuits]

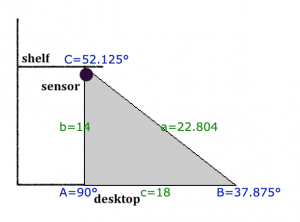

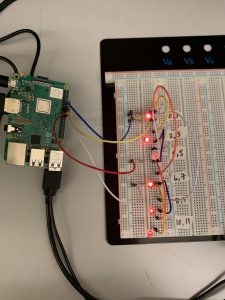

This week I implemented our Charlieplexing scheme with 4 pins and wrote up the Python code to drive those LEDs in groups (see photo below). We’ll be using a single LED per carrel and have them lit for available desks and unlit for occupied desks. From a design perspective, this is cleaner and less intrusive for a space that’s meant to be quiet and distraction-free. From a cost perspective, this allows us to maximize the number of carrels per sensor hub to 12 (charlieplexing works in nP2 permutations, and 4P2 = 12). My reanalysis of our schematics means that we can fit 5 more carrels per RPi than the 7 we had originally expected.

[System]

[Demo]

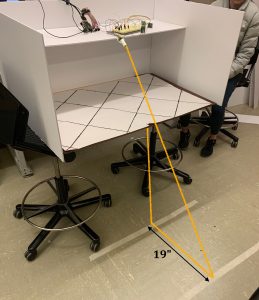

Our foamboard carrel tops are built and ready for demo. I still need to source some plywood for Monday’s demo, but the workbenches in the Design Studio in Ansys Hall have wood tops that should suffice.

We’ve successfully wired together and built a single carrel with a sensor hub, running with just the RPi and no monitor. Accurate occupancy and capacitive data is being sent to the server.

[Risks]

Going into this week, Charlotte is out of town for 10 days, which means I am on my own to pull together our project in lab by the Monday in-lab demo day. It’s a significant amount of work but doable over the next week as I’m in town through Thanksgiving break. I’m also feeling pretty uncertain about the success of the capacitive sensor, but Charlotte is confident in making it work. It seems to work perfectly on a small scale but has issues when implemented as a large grid.

My deliverables for next week:

- Solder the sensor hub breadboards to be mounted next to the RPi — power line, ground line, PIR sensor I/O x12, LED drivers x4

- Attach female jumper ends to all wires for easy mobility and plug/unplug connections

- Fix Python script to run LED loop alongside PIR sensor loop

- Finish cleaning up the UI

- Add email notification code, as triggered by capacitive sensor readings

- Assemble full demo setup with three carrels

- Test and adjust capacitive sheets until reliable