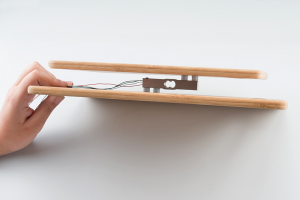

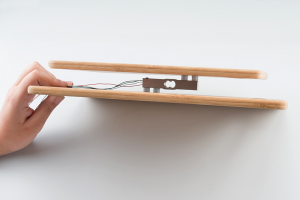

Bill: I looked more into how we could set up the load cell that we purchased. We would most likely be setting it up like the picture below.

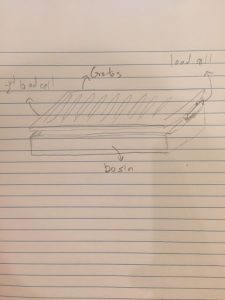

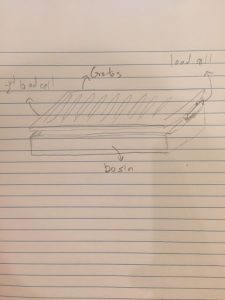

However, we are considering putting a sort of basin underneath where the drink is getting dispensed, and putting a grating platform on top of the platform so that a glass can be placed on top of it. It would be very similar to the platform for a soda dispenser, like below.

This would be for collecting any drops, as well as the water used to clean the system between drinks. This complicates the load cell system, as the load cell needs to be able to sense whether a glass has been placed on the platform without getting wet. One solution is to put the 2 load cells on each side of the grates, like below.

This would require reading from 2 load cells at the same time, and coordinating and configuring the readings. The readings do not need to be too accurate, as this is just for sensing whether a glass has been placed or not.

For pumps, we ordered 2 pumps, a peristaltic pump and a regular submersible liquid pump. The peristaltic pump has to problem of possibly not being able to pump fast enough. The other pump is a lot stronger, and it has the issue of possibly being too strong and hard to control. Also, this pump has to be submerged in water, which is not ideal, whereas with peristaltic pumps we just need to put the tubes in the water and the actual motor stay out of water. We might be able to alter the pump rate by just altering the amount of voltage we feed into it. We will need to test these pumps out.

We looked into possible alternative pumps and found these:

https://www.robotdigg.com/product/686/12V-volume-flow-rate-dc-motor-or-stepper-peristaltic-pump?gclid=EAIaIQobChMIgI7ysPrY3QIVjFqGCh0ouwyXEAQYFCABEgI1tPD_BwE

https://www.robotdigg.com/product/1035/Stepper-motorized-openable-head-peristaltic-pump?gclid=EAIaIQobChMIgI7ysPrY3QIVjFqGCh0ouwyXEAQYBSABEgLhfPD_BwE

These are stronger, so they might work better for our project. However, there is no documentation available for these products.

Next week, I will do testing on the load cell and the pumps. Ideally, we would test early in the week so we can quickly order any new pumps that will meet the requirements for our project.

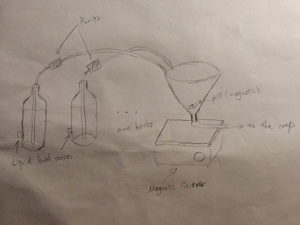

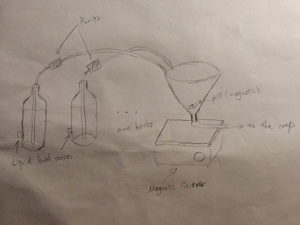

David: Last week, we were settling down on the actual design of the entire system. We came up with two designs that we thought might work and would further do the testing to decide which design is better. The first design is to pump the liquid directly from the bottle, as the photo below. However, we had the problem of pumps not powerful enough and having to put the pumps inside the bottles, as Bill mentioned above.

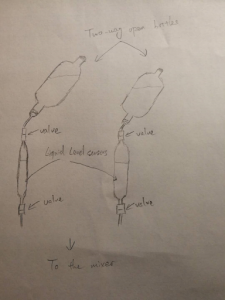

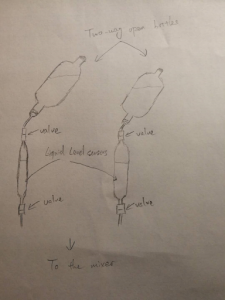

Thus, our second design doesn’t use pumps anymore, but to control the flow with valves and gravity. (Graph below) However, almost all the valve we looked at require an at least 3 psi in order for the liquid to start flowing, which apparently we can’t achieve. Luckily, we found a valve online which claim to operate with little to no pressure at Adafruit. In this way, we would be able to control the amount of liquid and detecting liquid level more easily.

In our new design, we use two-way opening bottles so that we can simply add liquid into the bottles without changing to new ones and avoid the installation as well. In order to control the flow of liquid, we want to use a reservoir system, which includes a container and two valves. The valve above controls the liquid flow from the bottle. The bottom valve holds until we get the right amount of liquid within the container, which is detected by a liquid level sensor.

Even though the new system doesn’t require pumps to operate, we still need to test out the pumps, because there are liquids like syrup that might still require pumps in order to come out quick enough to meet our goal.

Thus, for next week, we need to test the flow rate and power of different kinds of pumps. Also, we need to test to make sure the new valve can operate in little to no pressure condition. Moreover, we need to test out different kinds of liquid level sensors. Based on the results of the tests, we should come up with a full design of the entire system.

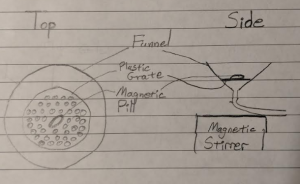

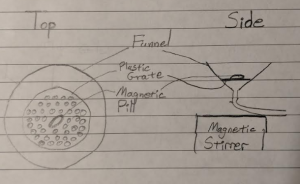

Connor: Helped design the general structure of Bartendo with regards to the mixing station. I focused on how to mix the liquids from the various containers. The conclusion that we came to is to have the container hang from above. For us, this container would be a funnel, which will naturally drain out all of the mixed liquids that are in it. Also, there is also the product requirement where we need to mix the liquids once they have all been dispensed from their respective bottles. To do this, we will use a magnetic mixer stirrer that has a base that applies a magnetic force to a magnetic pill (which is in the drink) that will stir the drink. There is an issue though: the pill must be on a level surface and shouldn’t get stuck in the drainage hole in the funnel. Elsewise, the stirrer will not function properly. We can, however, avoid this by creating a filter that will lie at some level in the funnel, where the magnetic pill can sit and spin when the base platform applies the force. Also, with holes small enough, the filter will act as a grate, allowing the liquids to drain out of the funnel and preventing the magnetic pill from being caught in funnel’s drainage hole. We decided to create a “makeshift” filter by buying a plastic disk that will fit at some level in the filter and drilling tiny holes in it to both allow the liquid to drain at a fast enough pace and the magnetic pill to spin properly. To get a sense of what we had in mind, see the diagram below.

We still have to find a way to dam up the liquids to prevent them from pouring into a cup. After the liquids are poured into the funnel, there needs to be a way to keep them there. If not, they will simply be drained into the cup without being mixed. To prevent this from happening, we will use a gravity-fed valve at the bottom of the funnel which will be attached to silicone tubing that will lead to the cup.

Next week, I will need to order the magnetic mixer stirrer, funnel, plastic disks, and gravity feed valve. Once the stirrer gets in, we should double check to make sure that it will create a strong enough magnetic force even if the magnetic pill is not “sitting” on top of the base.

Overall:

Overall, there were a few changes to the design of Bartendo as was mentioned above for various reasons. However, I believe after this week, we should be down with most of the testing of our components. Because we should have our components by early next week, we should be able to begin and hopefully finish testing of said components. This will help us finalize the design of Bartendo. Even though there is some uncertainty with certain components, I think we have done a good job at minimizing the risk of things going wrong by thoroughly thinking of other designs that could serve as a contingency plan. Thus, here is the updated schedule: