What did you personally accomplish this week on the project?

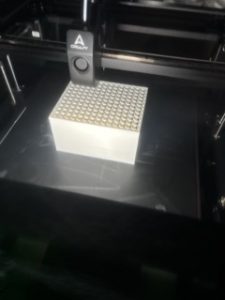

This week, I helped with the end-to-end testing to make sure that we are ready for the demo. With the rest of the team, I helped verify that the arm was able to pick up boxes off the treadmill at 0.5mph and place them in the correct bin. I helped time the runs, and we found that the arm was able to sort the bins at 10 boxes per minute, so we were very happy with that. Other than that, I continued making progress on the final report by adding the system implementation, ethics, and summary sections. I also finalized the bill of materials and am working on the final Gantt chart for our report.

Is your progress on schedule or behind?

Our progress is on schedule!

What deliverables do you hope to complete in the next week?

Next week, we will focus on the presentation. We are planning to demo the robotic arm, so we need to make sure that it goes smoothly. Once that’s done, we will work on the final poster, video, and report for the following week. We are pretty much done in terms of implementation and are mostly looking to wrap things up well.

Supplement

Personally, I used a lot of online resources to learn what I needed for this project. I had no prior experience with robotic arms before this, and I found online articles and videos very helpful. My main responsibility for this project was the kinematics engine, so I used a lot of online articles to learn the math behind everything. I also used online forums for Arduino help since it’s been a long time since I wrote that kind of code. I’m not much of a textbook person, so I find online resources very helpful because they are more focused and to the point. In terms of learning strategies, I made sure to never rely on a single website/article for anything. Whenever I found some important piece of knowledge, I verified it with another source. This was to gauge how many people approach similar problems as opposed to looking at the problem from a single perspective. This gave me the freedom to use different aspects from different sources.