Mark McKinzie – Team C8

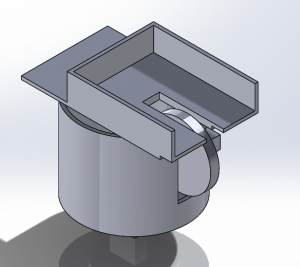

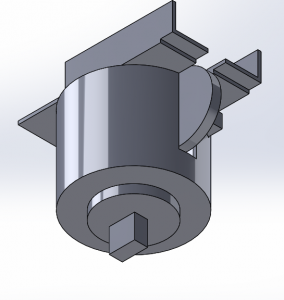

This week I as well as working on the design review document, and giving feedback to Eric on his practice design review presentations, I worked on designing the dealing module of the automated shuffler and dealer. As seen below it is a card tray mounted on a cylinder which will be rotated by the servo motor and wheel on the bottom. In addition I cut out a piece of the cylinder in order to accommodate the servo and wheel which which physically deal the cards. This will fit inside the tray that Chris designed and will have the shuffler from my report last week on top of it.

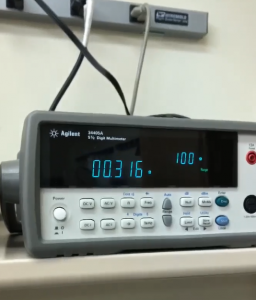

In addition I worked on fabricating the custom poker chip with embedded resistor. As is displayed below I drilled into the chip 4 times to create a slot for the resistor to fit in. However I hit a roadblock when I discovered the chips we purchased have a metal plane inside the plastic exterior of the chip. When I soldered the resistor into the chip and measured the resistance on either end of a 20k resistor and read 0.2 ohms. The good news is drilling and fabricating this chip did not take me much time, and it will be even easier to drill through a purely plastic chip. The bad news is we must obtain different chips to work with and that will take time.

Progress is on schedule for the shuffler/dealer and next week Chris and I plan to merge the three designed assemblies together and have a final design to present. Progress for the poker chips is behind, but I can catch up next week simply by fabricating many chips, as I know the method of fabrication works, even some of our construction is faulty. I hope to have 1 chip of each value fabricated next week, as well as fabricating one contact for the chips which will rest in the play area.