This week, our team made significant advancements in hardware construction, software development, and system testing. Below are our progress:

Hardware Progress

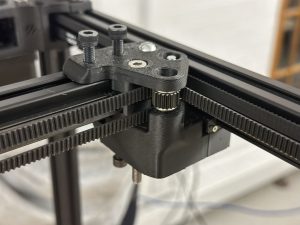

- Gantry System Development and Testing

- Completed the hardware assembly and testing of the gantry system, focusing on the X and Y axes.

- Addressed initial issues with belt vibrations caused by loose components. Adjustments, including tightening belts and securing nails, resulted in smooth and quiet movement.

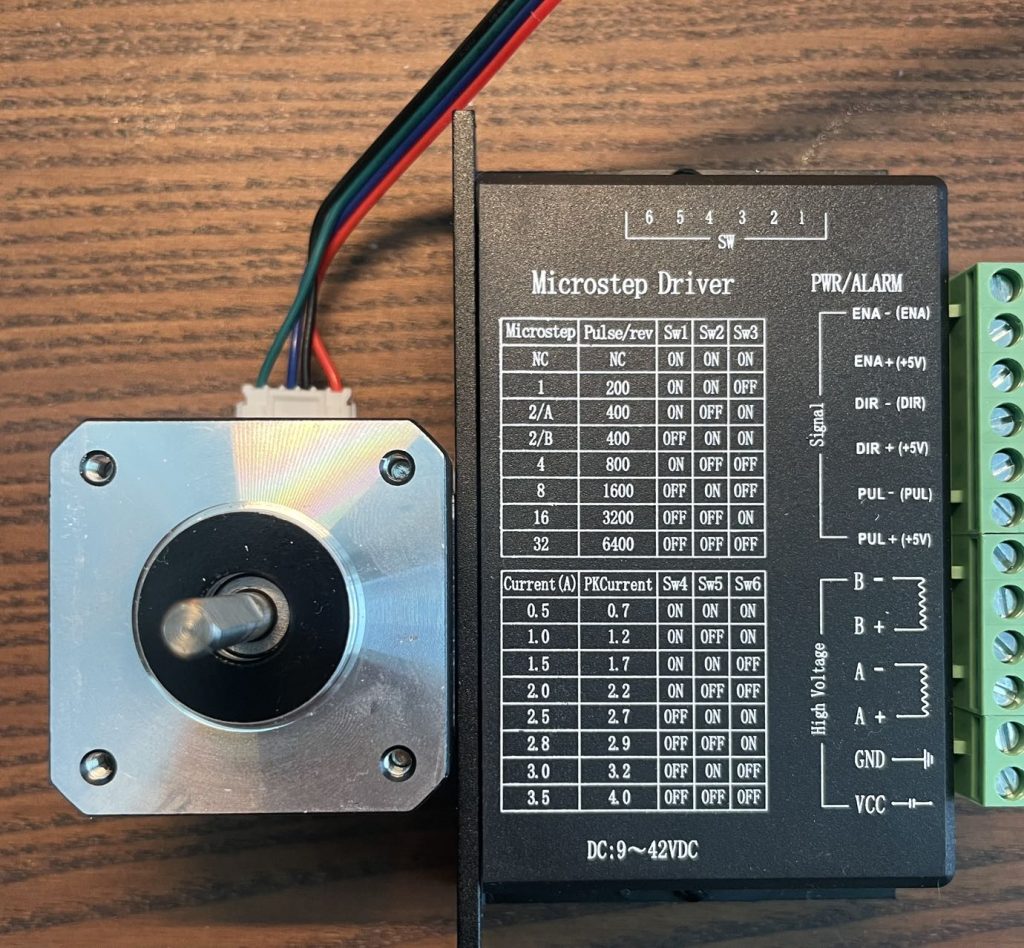

- Adjusted the motor configuration by reducing microsteps from 6400 to 3200 and increasing the voltage from 9V to 12V to overcome torque limitations. This configuration successfully drives the belt system.

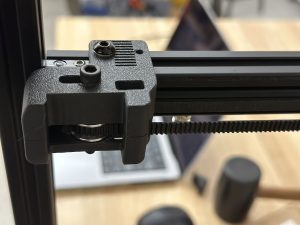

- Manipulator and Z-Axis Preparation

- 3D printed and assembled parts for the central manipulator to enable Z-axis movement. The manipulator will allow the charging pad to move up and down.

- Testing of the Z-axis is planned for next week upon obtaining the remaining components.

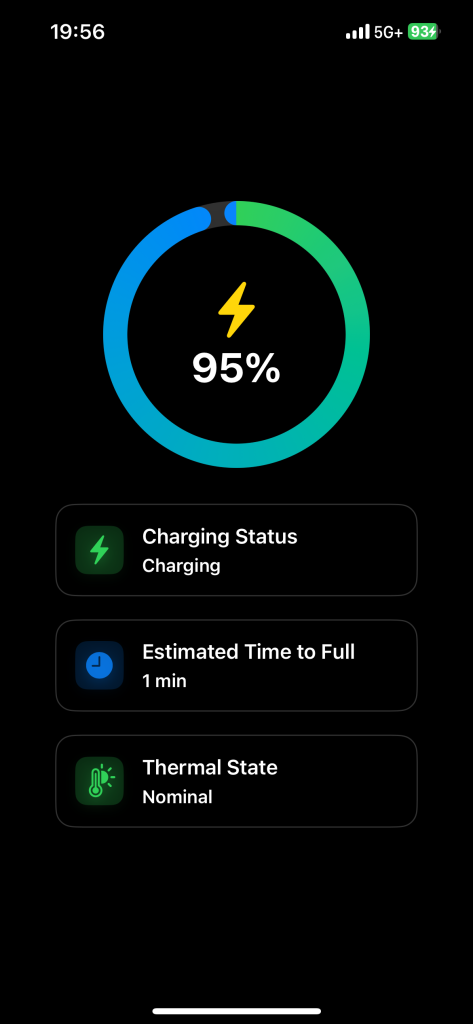

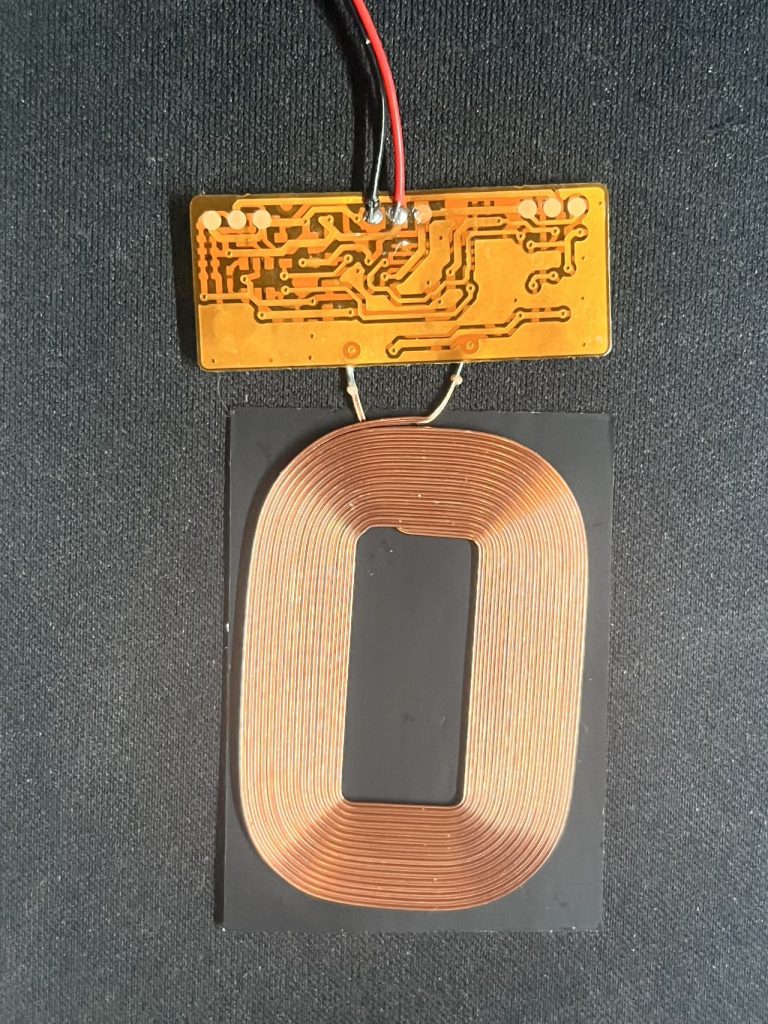

- Charging Coil Verification

- Tested 5W, 12W, and Apple’s original charging coils under 3mm and 5mm acrylic boards.

- Verified successful charging with the 12W coil for phones without cases on both thicknesses and with cases on 3mm acrylic. For 5mm acrylic, precise alignment is needed to charge phones with cases.

- Ensured charging safety by monitoring phone temperatures and confirming no overheating during operation.

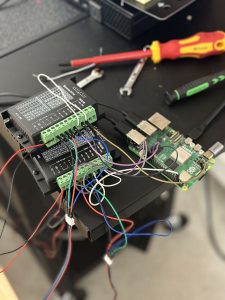

Software System Progress

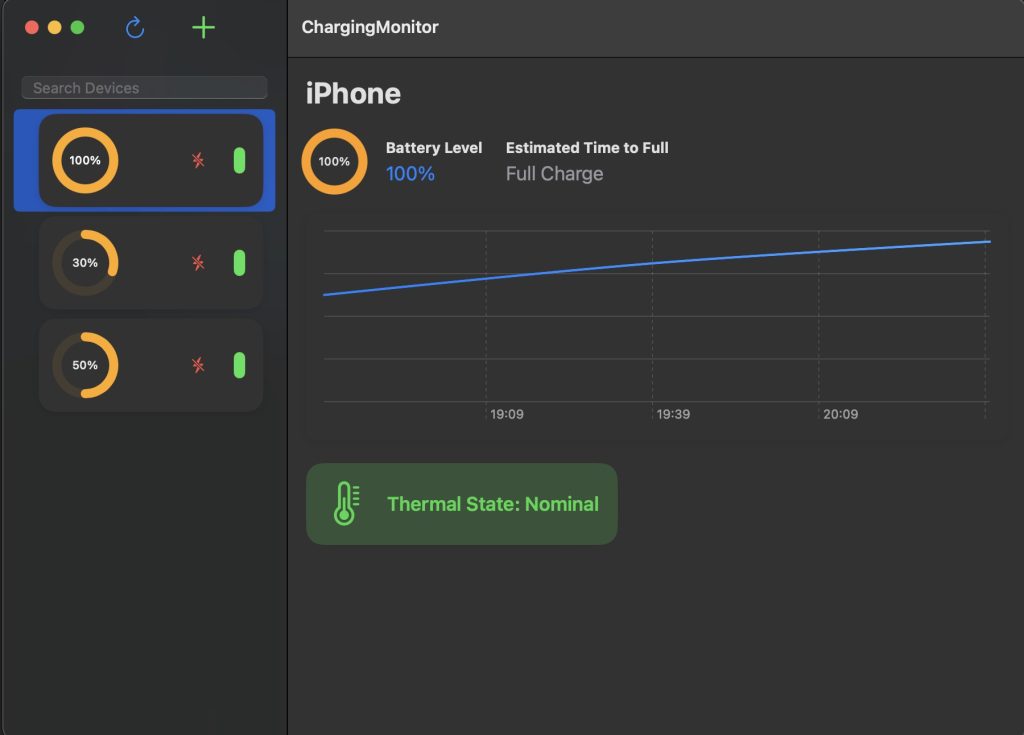

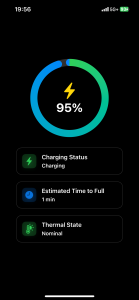

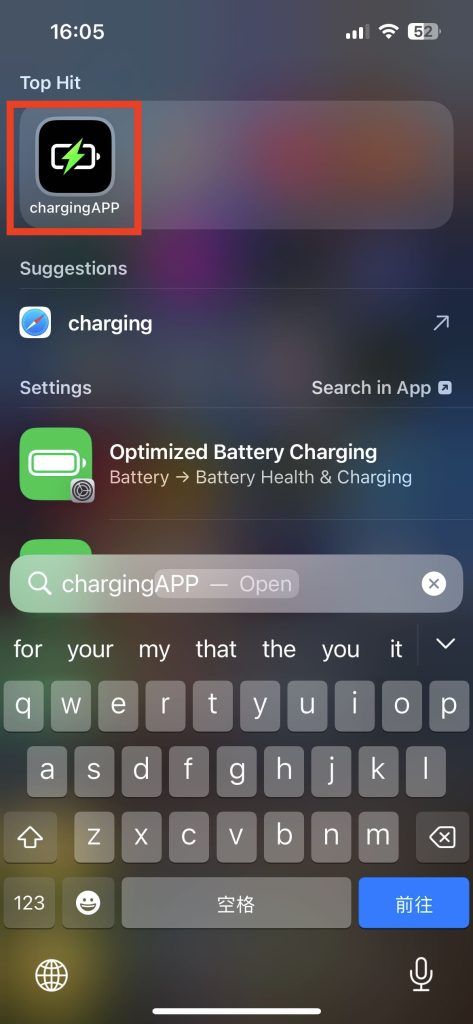

- Charging App Development

- Completed the development of iOS and macOS apps for real-time monitoring of charging status.

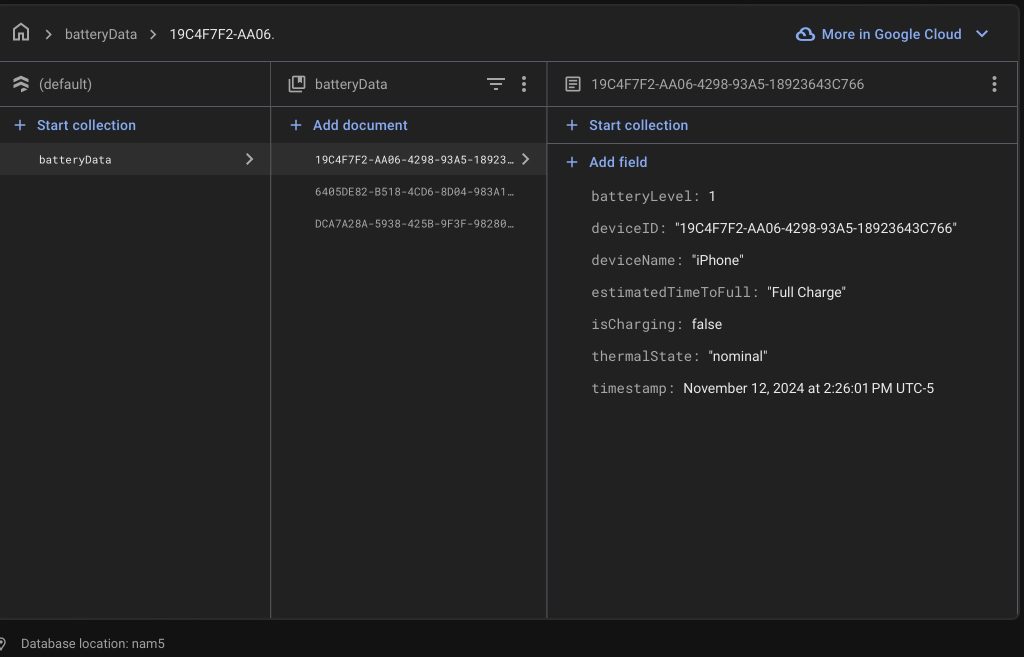

- Integrated Google Cloud Firebase for centralized data storage, enabling users to view and manage charging statuses across multiple devices.

- Conducted software testing to ensure real-time updates with an average delay of less than 500 milliseconds and consistent synchronization across platforms.

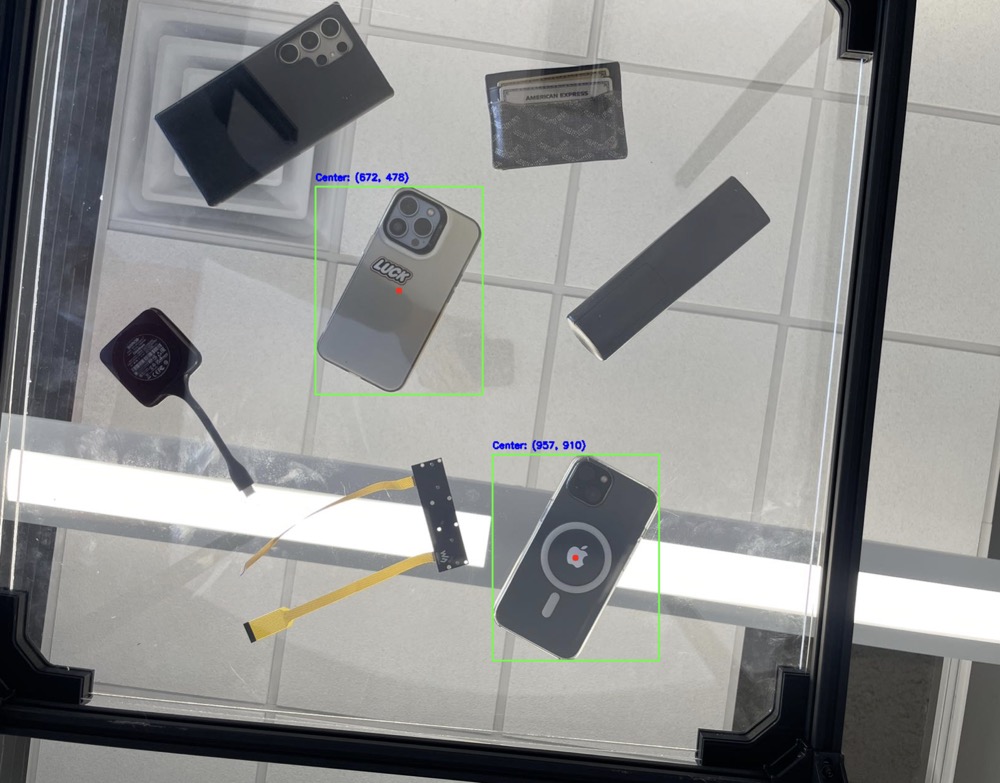

- Computer Vision System Development

- Finalized the object detection module, achieving 90% accuracy in phone detection.

- Implemented a two-frame difference technique to identify significant changes and avoid unnecessary YOLO model usage, improving performance.

- Enhanced the YOLO pipeline to detect phone locations and return their center coordinates with high precision.

System Validation

- Gantry System Testing

- Conducted repeated forward and backward movements to ensure smooth, consistent motion on the X and Y axes without pauses or obstructions.

- Confirmed that the gantry aligns with the intended design goals for X-Y movement, with full system requirements to be met after Z-axis integration.

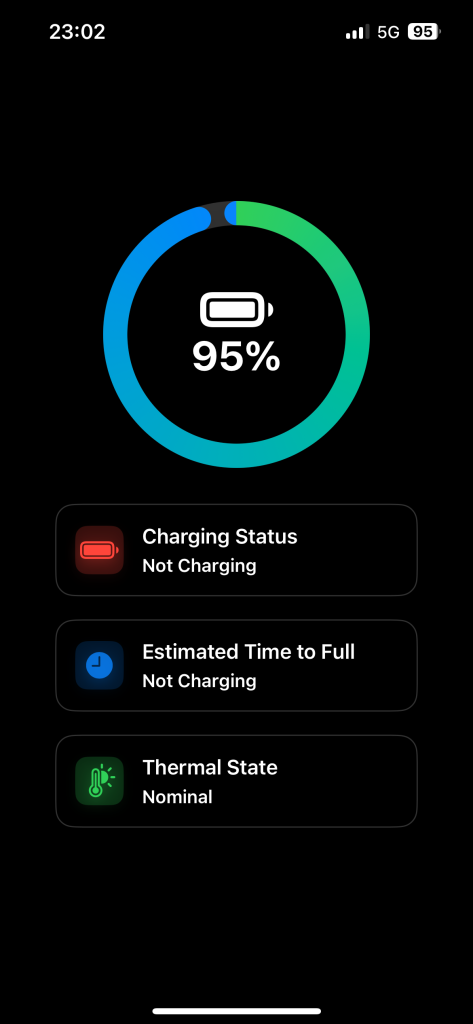

- Charging Coil Testing

- Verified that the charging coils meet design requirements for charging through acrylic boards without overheating.

- Confirmed compatibility with different phone cases and thicknesses of acrylic, with further testing planned to gather time-to-charge data.

- Software Testing

- Verified real-time status updates for multiple devices and confirmed data consistency between Firebase and app interfaces.

- Tested object detection under various lighting conditions and orientations, achieving high accuracy and minimal false positives.

Since we have not complete our project yet, it is hard for our current implementation to validate all the user requirements and the design requirements specified in our documents. Currently, we only validate that our system can detect phone < 1 seconds, software app information update < 500 milliseconds, and vision detection system has accuracy > 90%.

We believe we are currently on track.

Next week’s plan:

- Gantry System

- Assemble and test the Z-axis manipulator to enable full 3-DOF movement.

- Combine the central manipulator with the existing gantry system for complete testing.

- Charging Coil and Pad

- Redesign and 3D print the charging pad holder for the 5mm acrylic setup.

- Conduct experiments to determine the time required to fully charge phones with the 12W charging module.

- System Integration

- Begin integration of the computer vision system with the gantry system.

- Test communication between the vision system and the gantry for seamless control of charging pad movement.

- Further Testing

- Perform end-to-end testing to validate the entire workflow, including phone detection, pad movement, and real-time status updates on the apps.

Here are some pictures of our system:

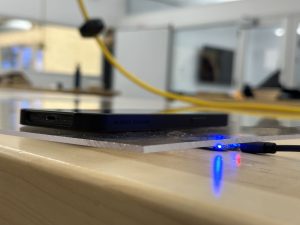

Corners:

Software:

Charging:

3mm board:

3mm board:

This meets the design requirement of successful charging. Further data will be obtained regarding the time to fully charge the phone.

This meets the design requirement of successful charging. Further data will be obtained regarding the time to fully charge the phone.

This component had already been submitted for printing at TechSpark on Thursday. We will gather the four pieces on Monday for further testing.

This component had already been submitted for printing at TechSpark on Thursday. We will gather the four pieces on Monday for further testing.