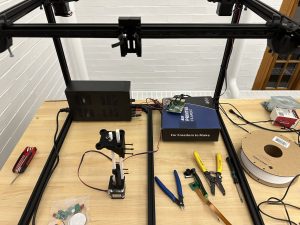

Based on our final presentation, the remaining for us contains software (gantry system tracking, alignment feedback control) and hardware (workload test and cable management)

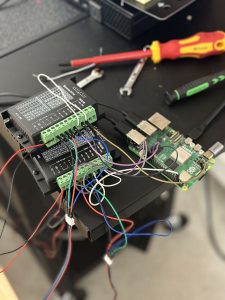

For the past week, after our presentation on Wednesday, we begin to test on charging pad alignment with the camera. The work I completed (primarily with Steven together for the hardware part) contains:

- Test original center manipulator. Use test code to let center manipulator drag the charging pad. However this configuration is not stable: sometimes can’t successfully drag; center manipulator very unstable with PLA shaft and rail. We tested for around 20 times, and around 8 times the center manipulator can’t successfully drag around the charging pad with wire. Therefore, we intend to modify the material of the center manipulator, the design of corner fasteners as well as the charging pads.

- Change to steel rail and shaft. Change screwing methods. Fix the shaft and rail right to the center manipulator. These changes are made to ensure the center manipulator is very stable and can successfully drag the charging pad.

- Help with corner fastener redesign and charging pad structure redesign.

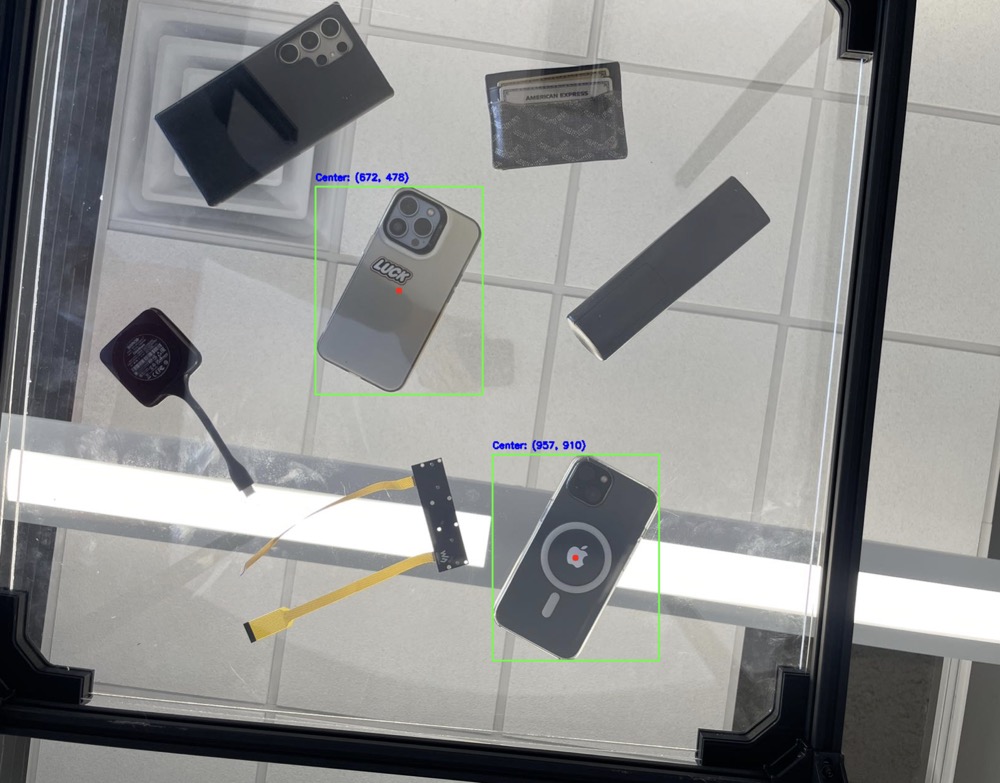

- Help with software integration tests. Camera detect phone –> gantry move charging pad to the position of the phone –> start charging. Still tuning

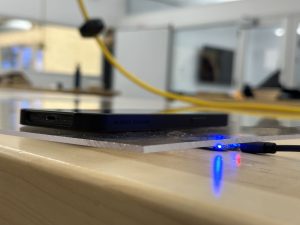

- We increased the distance between the two glass boards. Increased the height of the charging pad. This makes sure the type C wire does not come out the charging pad at the bottom. 20 trails were implemented and 18 trails completed. One fail trail the charging module was not fixed well to the charging pad. The other fail trail the manipulator failed to drag the charging pad.

- Fine tuning of the CV system was also implemented. We placed the camera at several different positions to ensure it can view the whole top of the table. Based on the fixed position of the camera, we record the position and begin to fine tune the movement of center manipulator. We transform pixel distance to real world distance and change input values for fine tuning,

Next week: Video, poster, final report ongoing. Overall on time. Still a lot of paper work to do.

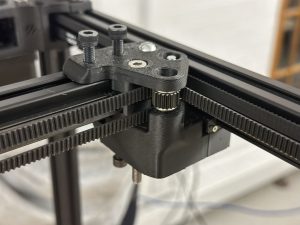

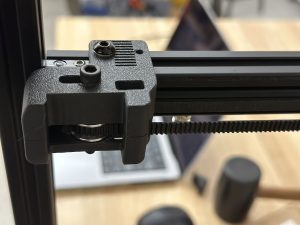

The problem that led to slow and uneven movement of the belt is the deformation of this 3d part. We reprinted this 3d part using ABS and it can then move on all x, y and z axis

The problem that led to slow and uneven movement of the belt is the deformation of this 3d part. We reprinted this 3d part using ABS and it can then move on all x, y and z axis

3mm board:

3mm board:

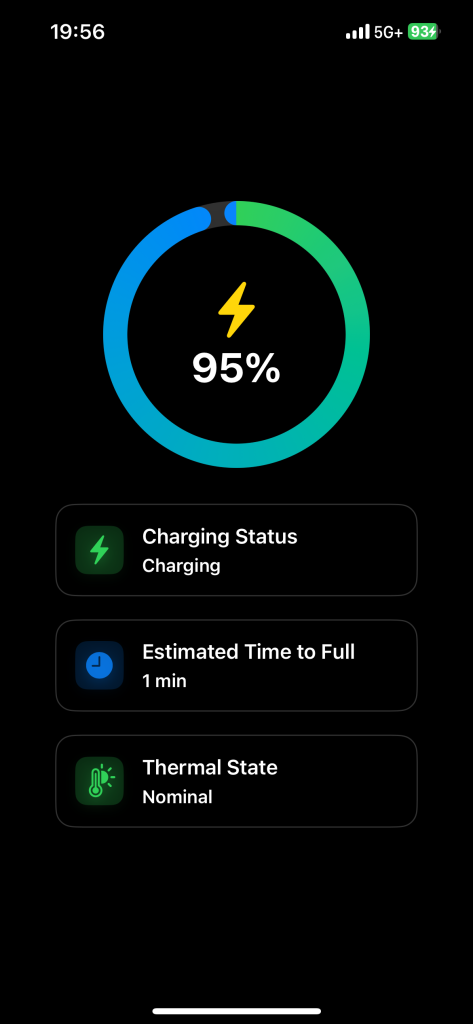

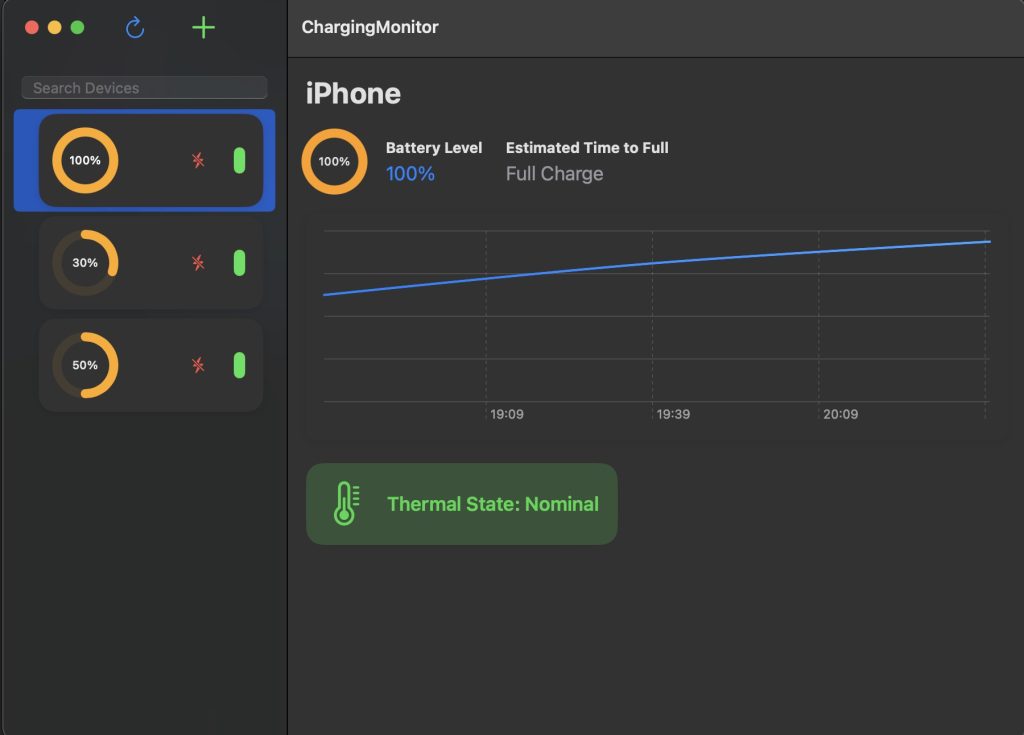

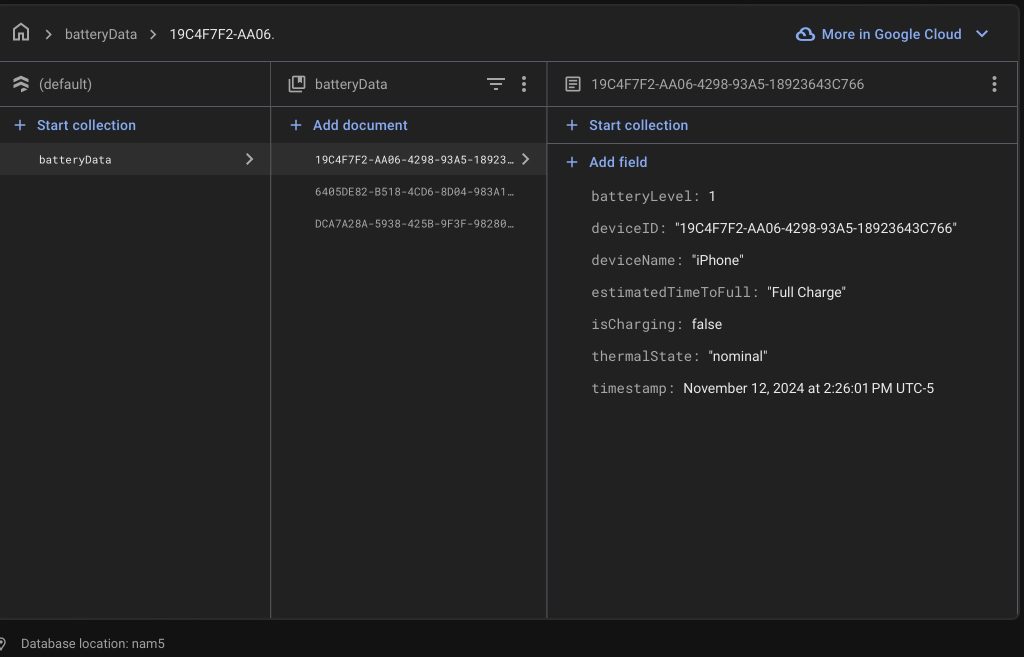

This meets the design requirement of successful charging. Further data will be obtained regarding the time to fully charge the phone.

This meets the design requirement of successful charging. Further data will be obtained regarding the time to fully charge the phone.

This component had already been submitted for printing at TechSpark on Thursday. We will gather the four pieces on Monday for further testing.

This component had already been submitted for printing at TechSpark on Thursday. We will gather the four pieces on Monday for further testing.