One of the highlights for our group this week was the development and completion of the mechanical hardware for the automated charging table. Utilizing aluminum extrusions, we built a robust and reliable platform that supports data acquisition and machine vision training while ensuring the necessary strength and durability.

Along with hardware advances, substantial progress has been made in the gantry system, particularly in the integration and control of stepper motors. By integrating the motor drivers with the Jetson Orin Nano, the motor control code has been enhanced to greatly increase the functionality of the system. A prototype of the gantry system has been produced and the conversion between the step length of the stepper motor and the corresponding conveyor travel distance was successfully realized. In addition, the PID control algorithm was fine-tuned to improve the motor accuracy, reducing the margin of error to within 5 millimeters over a distance of 30 centimeters. While this level of accuracy meets our basic control requirements, we plan to make further adjustments to achieve even higher accuracy for more demanding tasks.

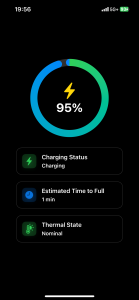

On the software side, we completed the design of the iPhone app, which now allows users to monitor the current state of charge, the estimated time to full charge, and the thermal state of the device. Future work will focus on integrating the app with web browsers and the macOS platform, allowing users to access device information while charging on their computers.

Looking ahead to next week, the plan is to mount the prototype gantry system to the main frame, using 3D printed parts to securely fasten components such as motors and belt gears. This step is critical to minimize vibration and ensure proper alignment during operation. Comprehensive performance tests will be performed on the assembled frame to assess the stability, accuracy and reliability of the system under real-world conditions. These tests will provide valuable insight into identifying sources of error and areas for improvement in the motor control algorithms and mechanics.

All in all, progress was made this week on both the mechanical and software portions of our project. The completion of the mechanical construction and enhancements to the gantry system’s motor controls have prepared us for the upcoming integration and testing phases. In the coming week, we plan to complete the overall construction of the system to ensure that the subsystems we designed in the mid-term demo are ready for basic functionality.