This past week, our team focused on advancing the structural, motor, and charging systems of the table. With the final structural components arriving early in the week, we examined the aluminum extrusions and connectors for the table frame, ensuring they fit within our design specifications. We created detailed 3D models using Fusion 360 and submitted critical parts, like the table corners and charging pad holders, for 3D printing. These components will provide support for the transparent layers and integrate with the gantry system, allowing precise positioning of the charging pad.

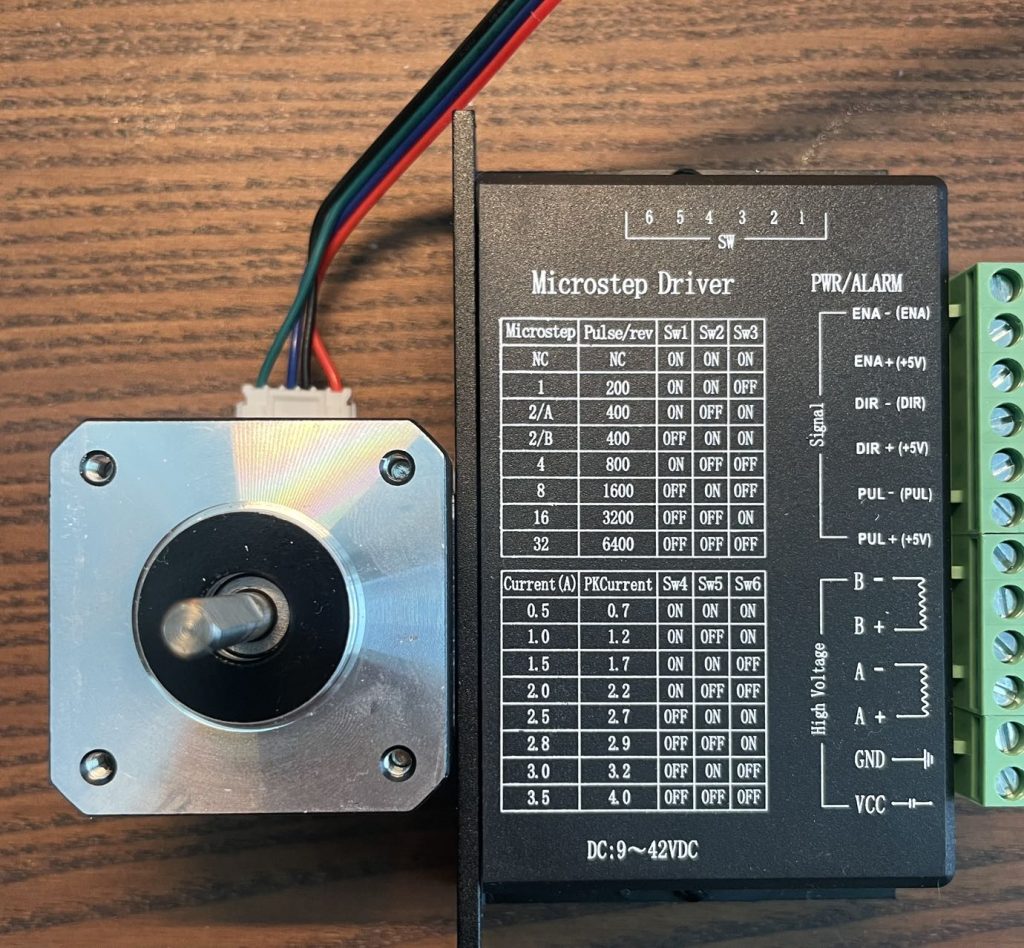

For the motor system, we configured the motors on the Raspberry Pi, establishing essential commands like turning and stopping. Leveraging compatibility with the Nvidia Jetson Orin Nano, we extended this motor functionality to the Jetson platform, which will allow us to translate coordinate data from the vision system into precise motor commands.

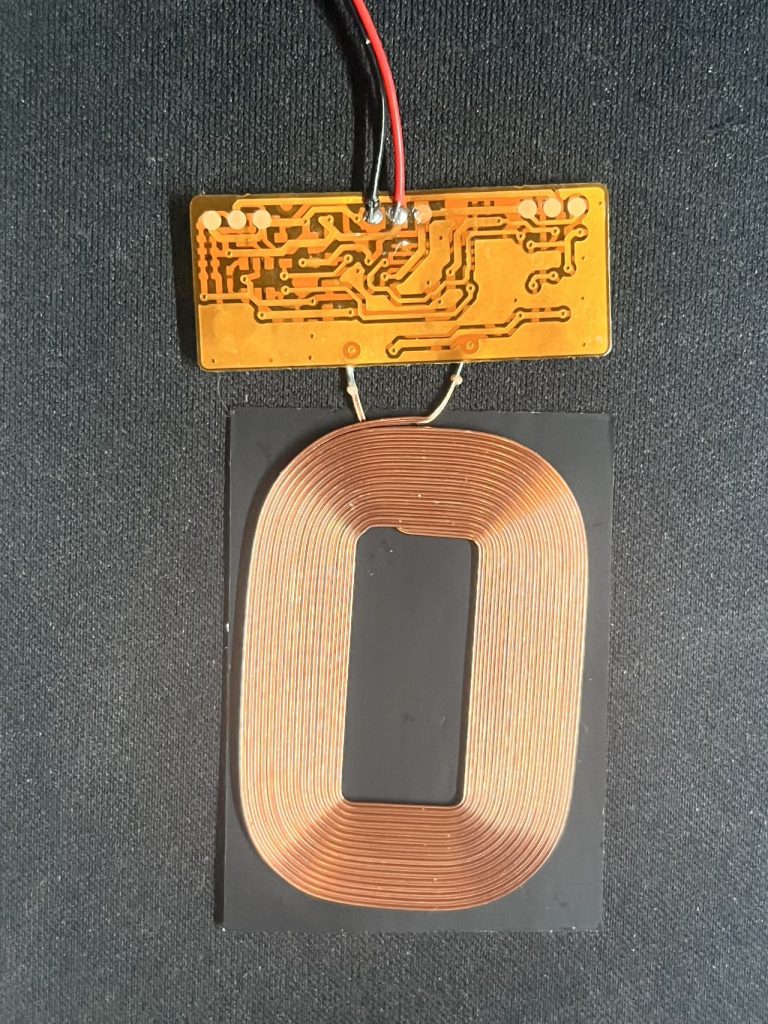

On the charging module side, we successfully integrated the charging pad with the Jetson Nano, establishing reliable communication between the two. Initial tests show that our setup can charge an iPhone 13 Pro in approximately 45 minutes. However, we identified stability issues with the charging pad, where it occasionally stops charging unexpectedly. We also experimented with materials and configurations to minimize interference from the gantry’s magnetic components, adjusting the design to ensure reliable charging without compromising the table’s layout.

We are currently on schedule.

Our primary objectives for the upcoming week are as follows:

- We will continue assembling and testing the structural and mechanical components, including verifying the 3D-printed parts for stability and functionality.

- We aim to complete the gantry system’s mechanical assembly and begin functional testing, focusing on motor control and precise movement based on coordinate inputs from the vision system.

- Enhancing the charging module’s stability will be a top priority to prevent disruptions in charging. We will conduct further tests to identify the root cause of the charging interruptions and make the necessary adjustments to achieve consistent charging performance.