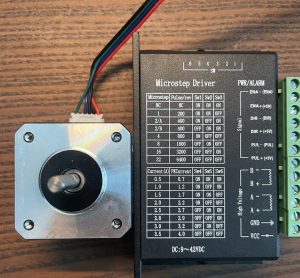

This week, my main focus was motor development. I successfully configured the motors on the Raspberry Pi using an external power supply to be able to perform basic commands such as turn and stop. Given that the Nvidia Jetson Orin Nano utilizes the same GPIO libraries as the Raspberry Pi, we were able to extend the motor control functionality to the Jetson platform, facilitating seamless integration with the motor driver. This compatibility provides a streamlined path for us to continue development on Jetson.

Despite these advances, I still need to accelerate the completion of the gantry system. It is important that we complete this work as soon as possible because it will allow us to translate coordinate positions directly into motor commands. This capability is critical to achieving the precise motion control we need for our application.

On the assembly side, Harry and I collaborated on the 3D-printed parts of the gantry and have made significant progress in building the structure. Next week, we plan to complete the assembly of the gantry system for functional testing. This phase will involve validating and assembling the mechanical design and ensuring consistency with the motor control logic. It is important that we complete the build and commissioning of this system as soon as possible, as we have created a partial gap between our process and our plan.

In addition, since the motor is the only component in our system that requires a high voltage range of 15V to 45V, we must determine the best way to fully power it. Our main challenge was to find a power solution that could be centrally managed to ensure operational safety. This required selecting a power supply or battery management system that could interface with our controllers, allowing us to safely monitor and control the power supply to the motors.