This week, I practiced more for my presentation before presenting on Wednesday and spent time figuring out the suction cup’s connection to the stepper motor. I found a shaft coupler that doubles as a mounting platform, to which I’ll attach a 3D printed mount for the suction cup that allows it to be rotated by the stepper motor while connected to the air pump. I ordered this, along with some more air tubing connectors and 3mm mounting screws (our stepper motor didn’t come with any), in our second amazon order. Our first amazon order and our adafruit order came in later this week, and I picked them up along with the 3D printed circuits mount (see electronics in github). The holes on the mount needed the slightest bit more clearance, so I added 0.25mm to the radius of each hole. We’ll 3D print it this weekend or next week.

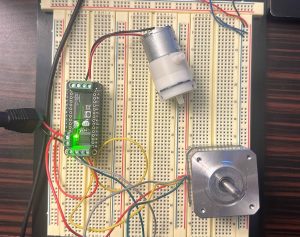

On Saturday, I started prototyping with the electronics that had come in from Adafruit and was able to control the stepper motor and air pump over serial. I’ve attached a picture of the setup below. Now I’ll wait for our new 3D printed mount, the suction cup, and the rest of the structure/hardware to come in before building a complete prototype.