- The past 2 weeks, I have been finalizing the hardware for the item stand and working on the final presentation. I have also been conducting some end to end testing.

- One main challenge I faced was the breaking of our system upon the addition of a new buzzer. We decided to add a new feature to the system by adding a buzzer and writing code that would allow the buzzer and our red LED to flash when an unauthorized change of weight was detected. Upon adding this functionality though, our wireless transceivers stopped working, essentially halting the functionality and progress of our project. Doreen and I spent several long days attempting to fix this problem and eventually managed to restore the item stand back to a previous state. Unfortunately we do not believe we have the time to implement this new buzzer feature without risking our system breaking again.

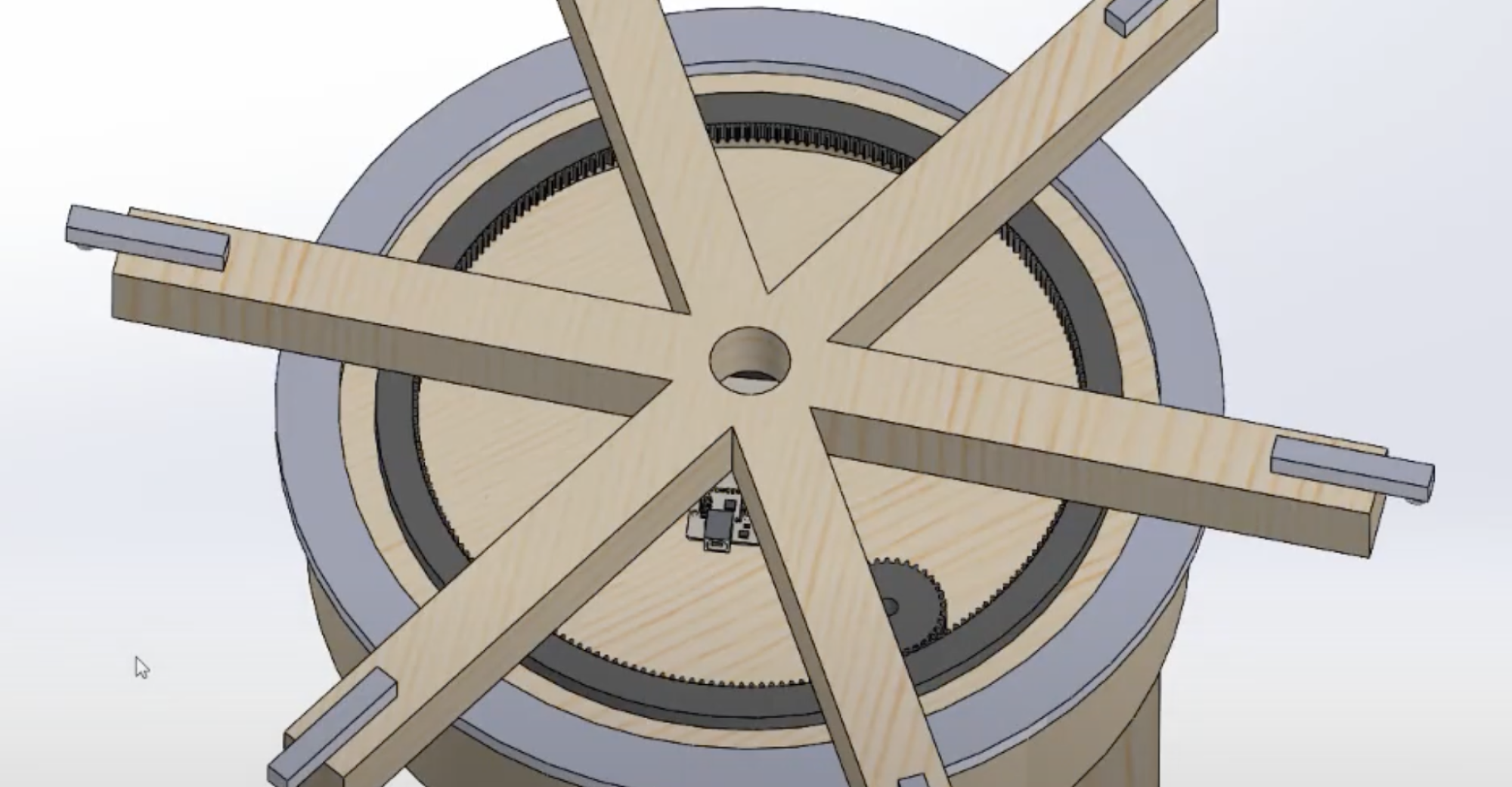

- This week, I worked on the final presentation and running some testing on the hardware. I conducted some item stand integrity tests, which consisted of adding weights to each of the load cells, adding weights on the item stand to make it imbalanced, and adding many weights to test the max weight bearing capacity of the item stand.

- Currently, I believe I am right on schedule. There were some hiccups in the past 2 weeks but I believe the preallocated slack time made up for that. I plan to continue testing, but start to focus my work on helping improve the software portion of the project.

- Next week, I hope to finish testing and wrapping up the project, as well as start on the final report.

WHAT I HAVE LEARNED THIS SEMESTER:

- This semester, I learned a lot about every aspect of the project I am doing, especially on the hardware end. Even in the construction of the item stand, I learned how to use a jigsaw, hammer and chisel, a sander, various drills, and other wood shop tools. It was also my first time assembling a large wood item and spray painting. I learned most of these things through online searching and lessons provided by some wood shop employees.

- On the electronics side, I learned a lot about the various components that went into the system. I learned about load cells, their calibrations and how they measure, I learned about how to use an Arduino microcontroller, I learned how to use wireless transceivers, I learned how to choose the right stepper motor for my project and which components are enough to power it, and more. Most of the knowledge I got to use these components came from the many tutorials I found online.

- Lastly, I dabbled in a bit of software. Before this class, the last time I touched Arduino code was in 18-100, which I took in my first semester at CMU (talk about full circle). I also spent a lot of time with various Arduino libraries, which I learned about through their documentation and other online resources. I learned a bit about how facial recognition and what algorithms go into it from talking to Surafel.