This week I worked on redesigning the stand, as well as re working some of the motor code.

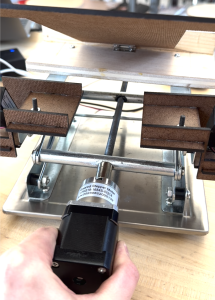

First, for the stand, I designed the lip, the flap and the linear actuator shelves. Through some weight testing on the shelves, I determined that two seperate pieces would be much lighter, which would lessen the load on the height motor. The first shelving unit I designed was not strong enough to hold the weight of the laptop, so I created another version that was stable enough. It will be connected to the stand via a 5/8 thick block that will be screwed into the top, with the two sides of the shelf screwed into it. I laser cut this, and made it extremely lightweight. For the lip, I decided that making this out of two wooden blocks (instead of laser cutting) was the only way to make it strong enough to support the weight of the laptop. I used pine wood because it is fairly light. And did some quick tests with the laptop to ensure that it is able to support it. I laser cut the flap as one T-shaped piece. I took some measurements to determine what the dimensions of the flap should be in order to keep contact with the linear actuators, and the lip. On the finished stand, the flap will be connected to the lip via a hinge. With these new components created, I was able to remove the metal top of the stand, which further lessened the load on the height motor.

For the motor code, I integrated the new code for the big easy driver, with the existing code for the linear actuators. I also wrote a simple turn-off function that will revert the stand to its base height and angle. I started implementing the rest of the FSM as well, meaning that the Arduino will no longer need to be reset each time the app is restarted. However, this code requires further testing.

I also did some research about gearboxes for the Nema 17, so that we would not need to switch to a Nema 23 motor, which would have required us to get a new driver and power source, which would have meant completely reworking the code.

While working on the project, I needed to create new components out of wood in order to preserve our budget and keep the top of the stand light. This meant learning how to use SolidWorks to create dxf files, and learning how to use the laser cutters in TechSpark. I was able to learn how to do this by watching videos online, and reading some articles about designing shelves. I also learned more about writing code for the Arduino, including using new libraries (AF_motor.h, ArduinoBLE.h, AFMotor.h, and Stepper.h, and AccelStepper.h). I was able to find tutorials online about how to do this. Furthermore, I learned how to implement Bluetooth communication between a mac and an Arduino. To do this I found some articles online, and also watched some videos.

Next week, I plan to have the stand design completely finished, meaning that all the top components are connected, and are the correct measurements. In addition, I plan to have the code for the motor and the linear actuators fully integrated and tested so that the stand moves as intended when given the correct serial commands.

I am a little behind schedule, but I should be able to have the hardware complete by the final demo. If needed, I will not implement the Bluetooth communication between the Arduino and the computer, as this is not necessary to achieve MVP.

The new components for the stand: