This week my workload was divided into three different categories: the first was finishing the final presentation and making sure our metrics for testing were presentable. I spent most of Sunday working on touching up the presentation and helping Varun prepare for presenting. The rest of the week I spent assembling the new pcb as well as the monitor setup for the user side. I also spent time working with Nathan researching how to pipeline the camera feedback effectively; we have made significant progress and I have no doubt it will be done by Wednesday. The latter part of the week has been spent drafting up our poster design and planning for the deliverables for this next week. A lot of the work we have been doing is to make sure our project is presentable this coming week.

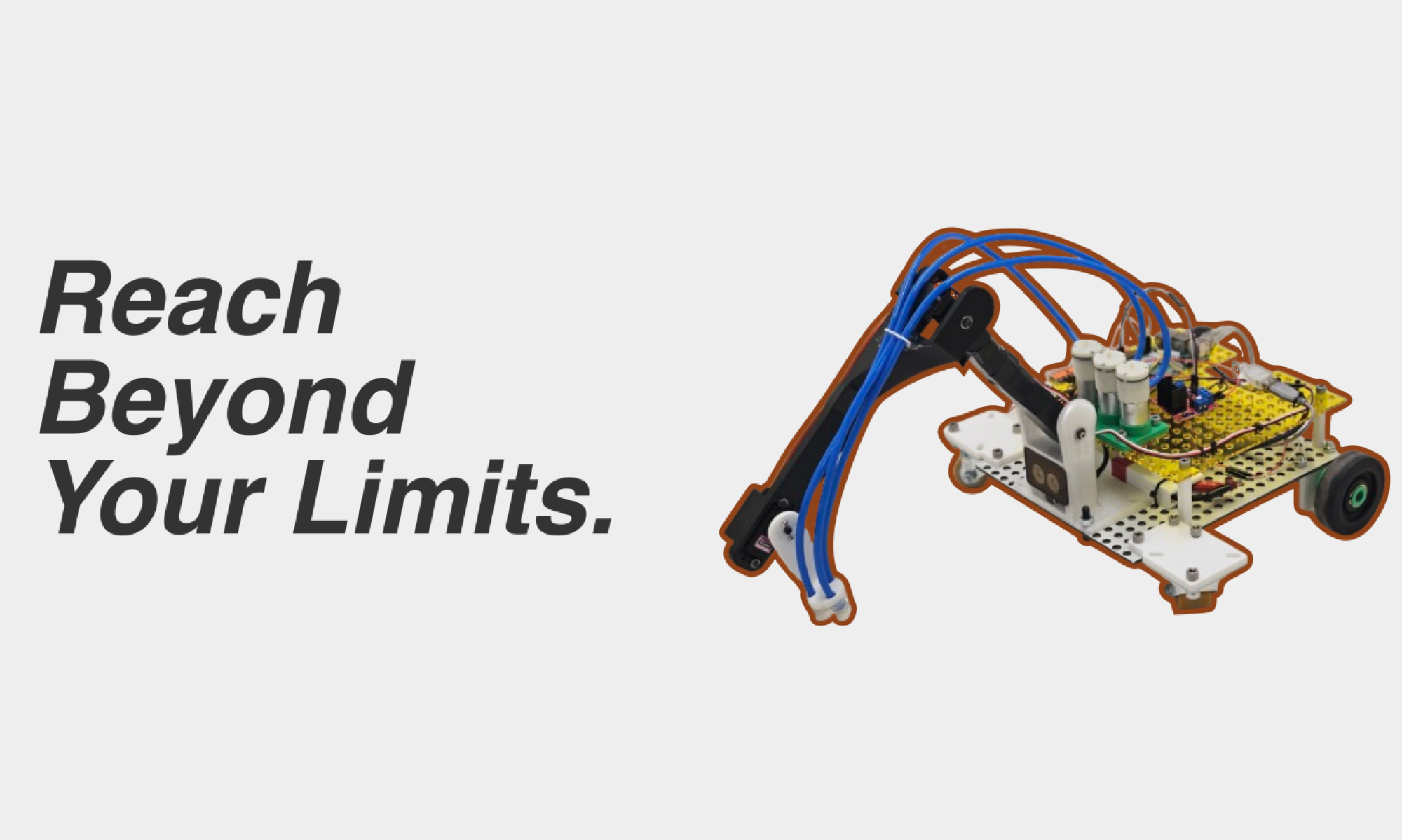

Image of the user side setup.

In order to meet our Tuesday deadline we have to finish our poster design; in order to meet our Wednesday deadline we need to get the camera feed working. I will be spending the next three days working closely with Nathan to make sure we get the camera feed transmitted as well as helping Varun wherever debugging and verification is necessary for the kinematics. No schedule changes need to be made and quite frankly we do not have the opportunity to make any.