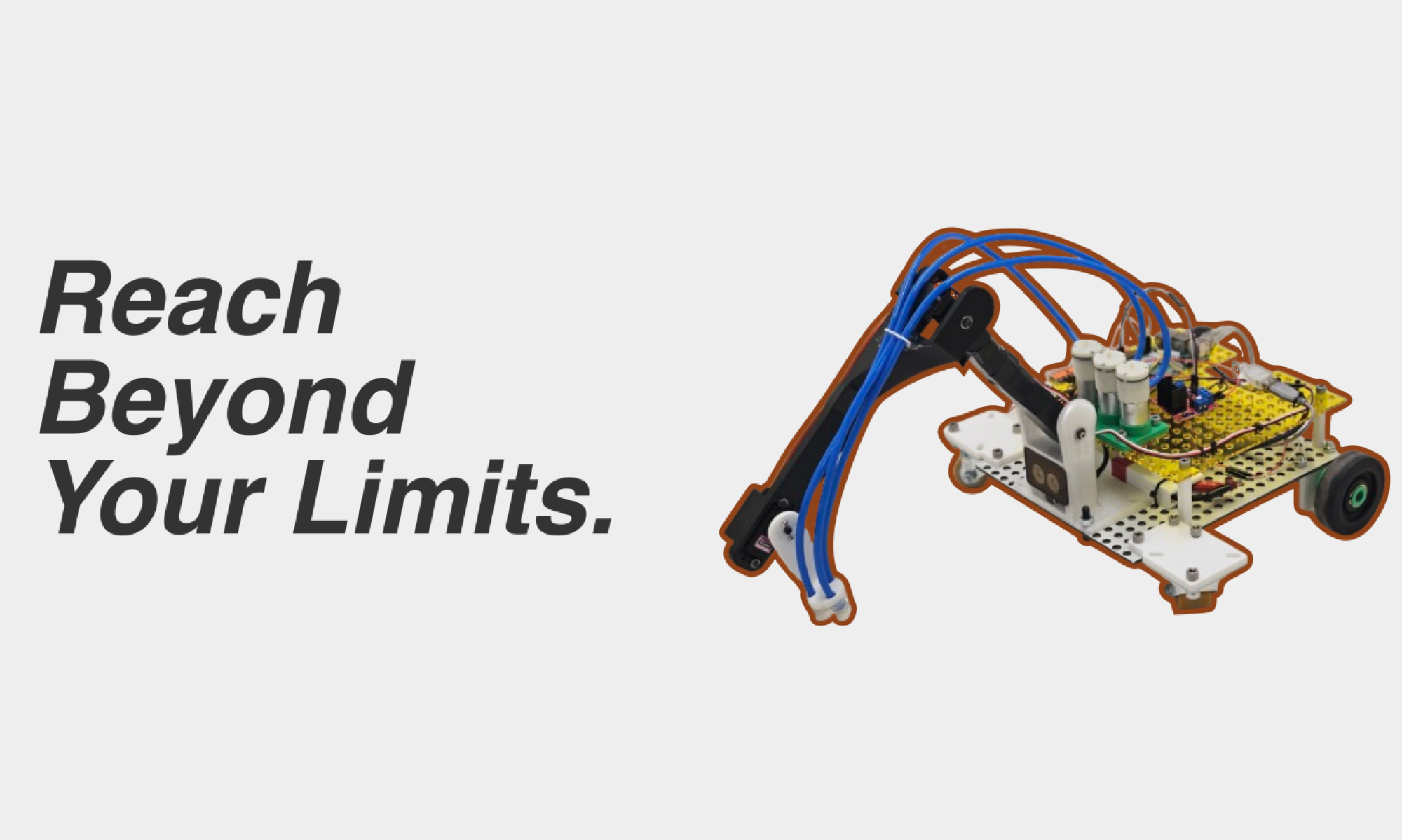

Currently, the most significant risks that could indeed jeopardize the success of the project are the actual suction mechanism reaching the desired target, and the vision of the objects. As we have successfully obtained the requisite depth camera, we will be able to begin actual work in experimenting with the hardware itself. In this way, we should actually be able to finish with the identification and location of the objects. Our concern, then, currently lays within the kinematics to reach the desired object. None of us are experienced in the kinematics side of robotics, mostly with fabrication, so we have deliberately stuck to a very simple, DOF-limited robot arm on the front of our robot that indeed should be easy to calculate with. There are many YouTube tutorials, and with the scheme that we have chosen, we already found an easy way to implement the kinematics. The devil, however, is in the details. We’re concerned at the moment about the physical implementation of these kinematics. Of course, we imagine that we’ll be able to tweak parameters and effect a change, but we’ll need to ensure that we have time to sit and tweak to ensure that things go smoothly. The block diagram of the system remains the same, but the suction design that Varun envisioned last week is a bit different from what he imagined; now we will use a DC air pump instead of a syringe to create suction. It will be a bit more expensive, but this way, we can ensure that the amount of pressure will be sufficient. Here’s a much more complete view of the draft version of HomeRover:

Part A: Varun

HomeRover, within the concept itself, is designed to meet the psychological and physical needs of those who are afflicted by a lack of mobility. Therefore, the consideration that we target is that of public health. As enumerated before, the purpose of the project is to exist such that someone who is essentially stuck in a chair can use it to grab objects around them with relative ease. As we mentioned during our proposal presentation, this idea came about due to a struggle that Hayden’s grandfather was facing. As he had recently broken his hip, he found himself stuck in a chair, with a small meter-long grabber that could not aid him to grab objects that were farther away from him that what his arm could reach. (that’s where our slogan, Reach Beyond Your Limits, comes from!) We saw an opportunity to consider his psychological and physical health, and we knew that we needed to take it.

Part B: Hayden

As far as social factors, our target audience is the elderly and our design has to be intuitive and fairly simple. We know that our design needs to be easy to use by people with minimal education on modern technology and computers, which is why our design includes a basic arrow key control system with a monitor. An additional social factor we need to consider is that older people are sometimes untrusting of new technology and might not want something like HomeRover in their home; while furthering our design we need to find a way to ensure our customers that we are not collecting data or violating privacy within their home. Lastly, when it comes to our target demographic we also know that people are more financially conservative when they are older; because of this, we have made our design as inexpensive as possible by 3D printing parts and designing our system on Raspberry Pi’s that can compute fast enough but are not super expensive.

Part C: Nathan

With regards to economic factors, the first of which we have considered is that of the system of production, specifically supply-chain availability. When deciding on Raspberry Pi’s for our main source of computing capability, one aspect we considered was whether or not there was a shortage in most major retailers. However, according to multiple websites and news sources, the shortage seems to be resolved, indicating that we would be able to produce units cheaper. As a result of this, we can reduce the overall cost of our product, appeasing our target demographic who are more financially conservative, as aforementioned. In addition, because we are 3D printing parts, there is less pressure on sourcing parts through distributors and jumping through the hoops of retailers; the agency in building and representing our design tangibly is in our control, not on the onus of third party manufacturers.