For the past two weeks, I’ve focused on cleaning up the aiming system and preparing for the overall integration. I’ve refactored the code to remove the unnecessary ipc communication between the networking module and the motor control modules.

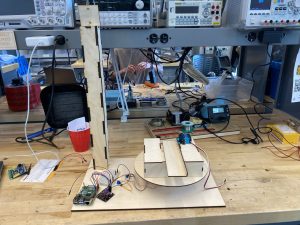

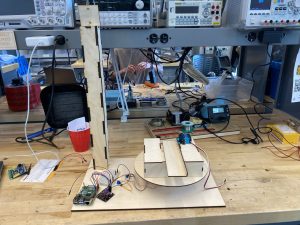

As the pressure system by Alex is working properly, I’ve redesigned the robot for full integration. Given that the pressure system’s pipe is rather thick and will need some spacing to bend properly, I’ve moved the balancing bridge on the lazy susan plate to the front and elevated the whole thing. I’ve also printed out a pole for the camera so it will be elevated by 50cm from the surface, and the whole base for the robot. The new physical robot looks like below:

I’ve also performed testing on the aiming system. I’ve set the angle of the vertical aiming and radial aiming system to various degrees, then took a picture of it to analyze the angle using an online tool like below. I’m still compiling the results of this to be included in the presentation next week.

I am on schedule according to our Gantt chart.

Next week, I will work on writing software on the pi to control the pressure system and put everything together, and work with Alex to run the vision algorithm on the pi, and work with Mike to connect the frontend to the pi properly. We’re at the integration mode and the lines between our responsibilities are rather blurry.

Throughout this project, I had to get out of my comfort zone and work with different tools – the biggest probably is CADing and physical design. I’ve only taken CAD class last semester and was new to laser cutting. I’ve had to read up on lots of other reference designs to design our robot. I’ve also asked for advice from Techspark and IDeate staff to make sure our design is feasible.

I’ve also had to learn how to work with microcontrollers, such as writing modules for motor controls and networking. I’ve followed lots of online tutorials to get the initial setup, then relied on documentation of specific libraries I was using to tune the code to our purposes.