What are the most significant risks that could jeopardize the success of the project? How are these risks being managed? What contingency plans are ready?

Currently, the main risks are physical – we have cadded and will print needed components to assemble our mvp for demonstration. We will need to carefully insulate non-waterproof electronics, make sure all components are securely in place, and sensors are properly secured as to provide reliable readings.

Were any changes made to the existing design of the system (requirements, block diagram, system spec, etc)? Why was this change necessary, what costs does the change incur, and how will these costs be mitigated going forward?

We made several changes over this week. We added turbidity and total dissolved solids sensors, and removed the capacitance sensor, as we found much more significant changes and less overlap in the liquids we want to classify. We also changed the system to use a single Adafruit ItsyBitsy board, rather than two. This is because all sensors we are using can be connected to a single board, and we changed the ultrasound to be attached to the body of the bottle rather than the lid. This will allow us to reduce power consumption, simplify the power supply systems, increase communication reliability (as we only need to communicate with a single board) and simplify communication logic (as we don’t need to synchronize data from two sources).

The cost of the added sensors is well within budget, and the other changes do not incur costs.

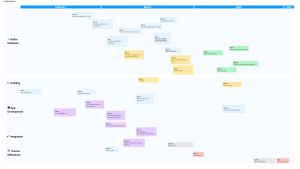

Updated schedule: