This week, the team traveled to their respective homes to visit with their families over spring break. This status report is intended to be combined with the status report from March 1st.

While work was limited due to traveling and rest, we focused on preparing our machine for the next step: integration. This included taking measurements and designing the custom frames and mounts for the components that will need to be mounted to the frame of the 3-D printer.

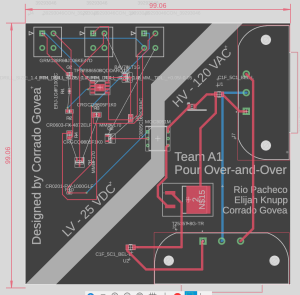

Part A: Written by Corrado Govea

The outcome of our project has users who are not tech-savvy in mind. While being a complicated system to produce the best quality coffee possible, we aim for anyone to be able to actuate the machine without having any prior experience with computer systems. An example of this would be our design requirement to have 5 loaded presets that users can easily actuate without having to program much. By having this goal in mind, we are greatly increasing the size of our user group and ensuring that we’ve removed one of the biggest barriers of entry to lots of “tech-centered” solutions nowadays. It is very unfortunate that lots of these great products are completely inaccessible to non-tech-savvy people, so we are ensuring that this will not be the case with our project.

Part B: Written by Elijah Knupp

When we first began considering creating a machine that would deliver delicious and convenient pour-over coffee, we were really only focused on creating the machine for individuals who did not have the time or desire to learn a new, detail-oriented brewing option. However, as we spoke to others and read several Reddit posts, we realized that this machine could also potentially benefit those who struggle with fine motor controls. Per the Reddit posts, the individuals who struggled with this spoke about how difficult (or impossible) it was for them to pour boiling water over coffee grounds in a controlled manner for extended periods (a task required for pour-over coffee). When they asked for suggestions on how to overcome this, most of the replies suggested that they find a new brewing method. However, we did not care for this answer. We fully believe that our pour-over coffee machine will solve many of the issues that these individuals are facing, even though there may be a cultural belief that they should “find a different brewing method.” We believe that this pattern of thinking (“let’s figure out a way” and not “try something else”) could increase the connectivity between different groups of people and bring joy to those formally excluded in some cultural activities.

Part C: Written by Rio Pacheco

Due to the wasteful nature of pod-based machines, we aim to provide similar ease of use without the need to buy coffee pods. The user will only need to use materials already used for pour-over coffee, which are paper filters and brewing devices. Paper filters are compostable and the brewing devices are reusable, thus making pour-over a much more sustainable option compared to pod-based coffee machines. Also, by giving people the ability to use any ground coffee they have, they can support local cafes and buy sustainably sourced coffee rather than being forced to purchase coffee in pods that were likely sourced from underpaid workers. Overall, our solution gives people a more sustainable and eco-friendly option to brewing coffee without compromising on ease of use.

… with consideration of environmental factors. Environmental factors are concerned with the environment as it relates to living organisms and natural resources.

Schedule is currently on track.