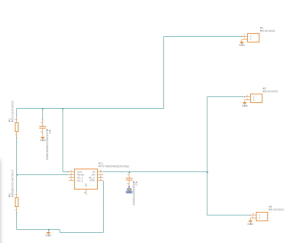

This week, the team focused on finalizing plans for implementing the different features and requirements for the automatic pour-over coffee machine, with the idea of purchasing the parts and products needed for those plans early next week. After some thought, our team is approaching our machine with this mindset: “If a reliable solution for one of the components currently exists, why try to reinvent it?”. Now, of course, this approach comes with its challenges. Take our current plan for the water heater. After determining that the other coffee-specific water boiler’s water capacities were too small, we now plan on purchasing a portable water boiler from Amazon. Normally, this unit is plugged into a receptacle and cannot dynamically alter the temperature it heats water to. However, by custom designing a 3D-printed lid, we can integrate sensors into the boiler. Now, using the outputs from those sensors, we can use a PID control loop to heat the water to the desired temperature. Additionally, we will swap the provided power plug with one that can be integrated into our custom PCB. We will take this approach to many of the components within our pour-over machine, including repurposing a 3D printer to use as our gantry. Overall, this week was essential for determining what products we need to purchase so that we can begin tackling the biggest challenge of this project – integration.

Part A: Written by Elijah Knupp

While there are no current issues related to public health at the moment (due to us minimizing the environmental impact that our machine will have), we will continue to consider this point as we design and create our pour-over machine. Regarding public safety, it is a top priority for us. We fully realize the potential risk of boiling water and will ensure that the user will not be in any danger (under normal usage) of coming into contact with boiling water. This includes creating and thoroughly testing our pouring system to ensure that no water splashes or is poured outside of the brewing device. Additionally, we will verify that all surfaces are touch-safe. Finally, we will only be using high-temperature, food-safe materials where required. Concerning public welfare, we do not currently see any risk of our machine potentially endangering it, as we consider coffee (specifically, pour-over coffee) to be a luxury good, so it has minimal impact on one’s basic needs.

Part B: Written by Rio Pacheco

By automating the pour-over process, we aim to cater to individuals with busy lifestyles who still value the ritual and quality of a handcrafted cup of coffee. This innovation not only saves time but also promotes inclusivity by allowing individuals with differing levels of expertise in coffee brewing to enjoy a consistent and flavorful cup. Furthermore, by incorporating user-friendly controls and customizable settings, our product accommodates diverse cultural preferences and brewing techniques, fostering a sense of cultural appreciation and community among coffee enthusiasts. Additionally, the machine’s efficiency and reduced reliance on disposable coffee pods align with growing environmental consciousness, reflecting consumers’ increasing concerns about long-term sustainability. Lastly, enjoying a cup of coffee with friends is often seen as a good bonding experience. Those who own our machine will be able to bring the specialty cafe experience home, giving opportunities for them to grow closer with their peers.

Part C: Written by Corrado Govea

Part C: We should look at this question from two points of view: the first is that our product is centered around open-source development. Hence, we are encouraging users to reuse parts of existing machines as part of their unit, making it a lot less expensive for the consumer, but also decreasing waste which has advantages at a higher level. The second point of view is for what we are proposing to sell as a unit — that is, is as a production model, we are aiming to make this product accessible by using electrical and mechanical engineering first principles to make each part of the machine as simple and inexpensive as possible — for example, by using a simple resistance heater instead of an over-expensive boiler for the heating element as found in an espresso machine. Lastly, once scaled, the total cost of the machine bought new — and its maintenance — would be significantly lower than most equipment in industry.

PRESENTATION LINK: https://docs.google.com/presentation/d/1-9KMpbVB5a8xJRN7go0xmVN7bswLXR9l0g2rxtNi6i8/edit#slide=id.g2ba2b52a80d_1_0