This week’s accomplishments

- Finished debugging the LV circuit.

- Identified issue with LDO voltage regulator not being able to handle the heat generated (Max 150 deg C)

- Currently .2A * 18V * ~50degC = 180 deg C

- Solution: We switched to a new pump, which is rated for 5V and 2A. Coincidentally, the power strip we got has a usb port rated precisely for 5V 2A, so we can power the pump directly from there. I need to get a new mosfet that is rated for this current to regulate the voltage drop across the pump.

- Identified issue with LDO voltage regulator not being able to handle the heat generated (Max 150 deg C)

- Continued debugging HV AC circuit.

- Currently only able to turn on/off — can’t regulate voltage at the output.

- Changed current limiting resistor to match optocoupler’s specification, but this still didn’t solve the issue.

- Was able to change the resistance across the output of the optocoupler by changing the voltage at the input, but the current delivered to the kettle is the same.

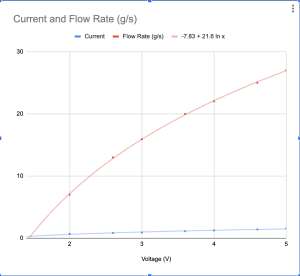

- Characterized new pump.

- Conducted test to characterize voltage across pump vs flow rate. The flow rate is a bit higher than we need, so we will design a flow restrictor to bring down to our desired rate. Pump seems suitable for our needs.

Next Week’s Deliverables

- Order new components (Monday) to match circuit design changes, and decide if it will be necessary to order a new PCB, or if we can repurpose the ones we received.

- If not, order new PCB by Wed at the latest.

- Continue to debug HV side to determine what is preventing from doing voltage regulation at the triac.

Extra: System Verification

- I plan to verify the pump controller circuit + code by running this test:

- After the entire system is installed, I will place a cup on the machine with a scale we have been using that has a flow meter in g/s. This way, I can verify that the set flow rate and actual flow rate are within the defined margins.

- To verify the heating element:

- our max expected heating time will be 3:30min, so we will run 5, 4-min trials where we set a desired temperature and monitor the water temperature to make sure it is within 5degF of the set temp. This will be tested at the outlet to account for heat loss through the pipes.

- Additionally, I will add a multimeter to the circuit to ensure that we are delivering current to the kettle as expected.

Status Report: On Schedule