This week I focused on iterating on the fabrication method for for braille slider actuator, and have the following results:

Size:

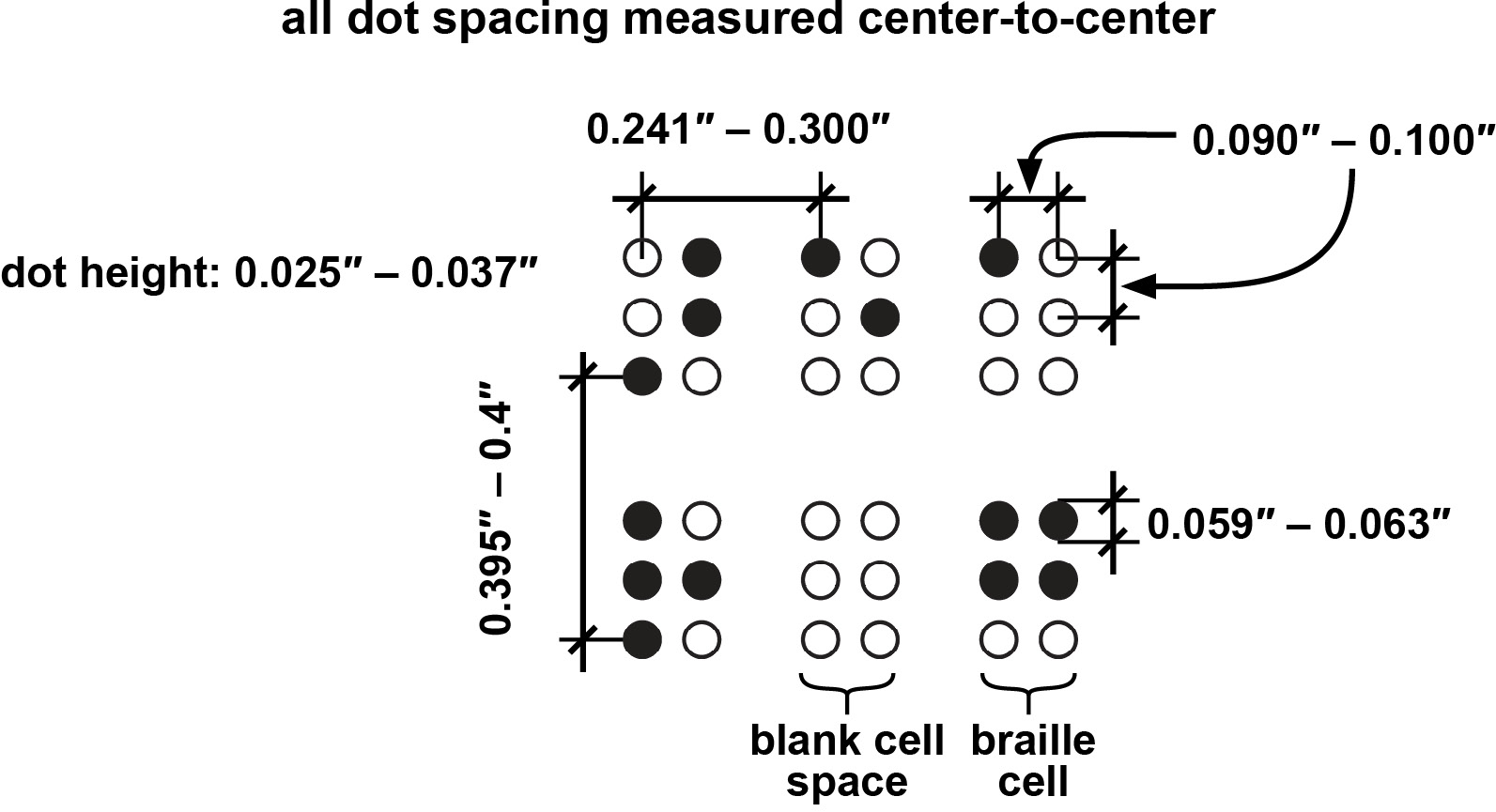

The ideal size requirement is shown above, which reflects the standards published by braille authority of north America. After several attempts to 3D print my CAD design in this dimension, I found that this miniature scale is nearly impossible to achieve, and the few actuator parts that did got successfully printed are all too fragile to meet our rigidity requirement. This is a problem that cannot be easily solved without major changes in our fabrication method and material, which we deemed outside of scope of this project and our open source requirement.

After much more testing and iteration, I have found that three times the standard sides provides easy fabrication while retaining a reasonably small size. The size of our tested module is still within limits because we have seen much bigger braille texts in use in public settings such as those in museums and elevators.

Deliverable for next week:

Next week, we should start integrating our electronic parts with the fabricated and tested actuator, in preparation of our interim demo. The end result should be a standalone 3×2 braille cell, that can be actuated by the Arduino nano controller automatically according to some set patterns in code.