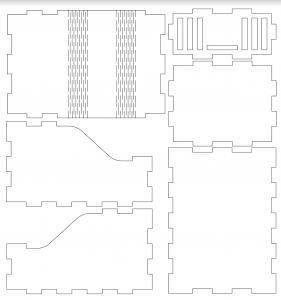

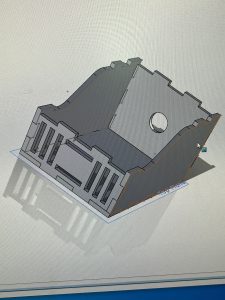

This week I worked on the design and assembly of the robot chassis and hardware. I made multiple adjustments to the CAD model in order to better accommodate our parts. First, the top piece of the chassis was too thick and inflexible to mold into the desired form factor, so I made adjustments to the front, back, and side plates to accommodate a thinner top panel. Additionally, I measured the dimensions of our motors and added supports to hold the motors and holes in the side panels to fix the axel. When testing out these supports, we found that the motors were not secure enough, so I drafted a new CAD design which ensures that the motors will not be able to move in any direction during operation. I will be laser cutting and testing this design as early as possible so that we can proceed with testing the calibration of the motors in the robot. I am currently behind on the sensor system assembly as one of our sensors has not arrived yet, but I will start working with our current sensors next week and help with the interfacing of these sensors.

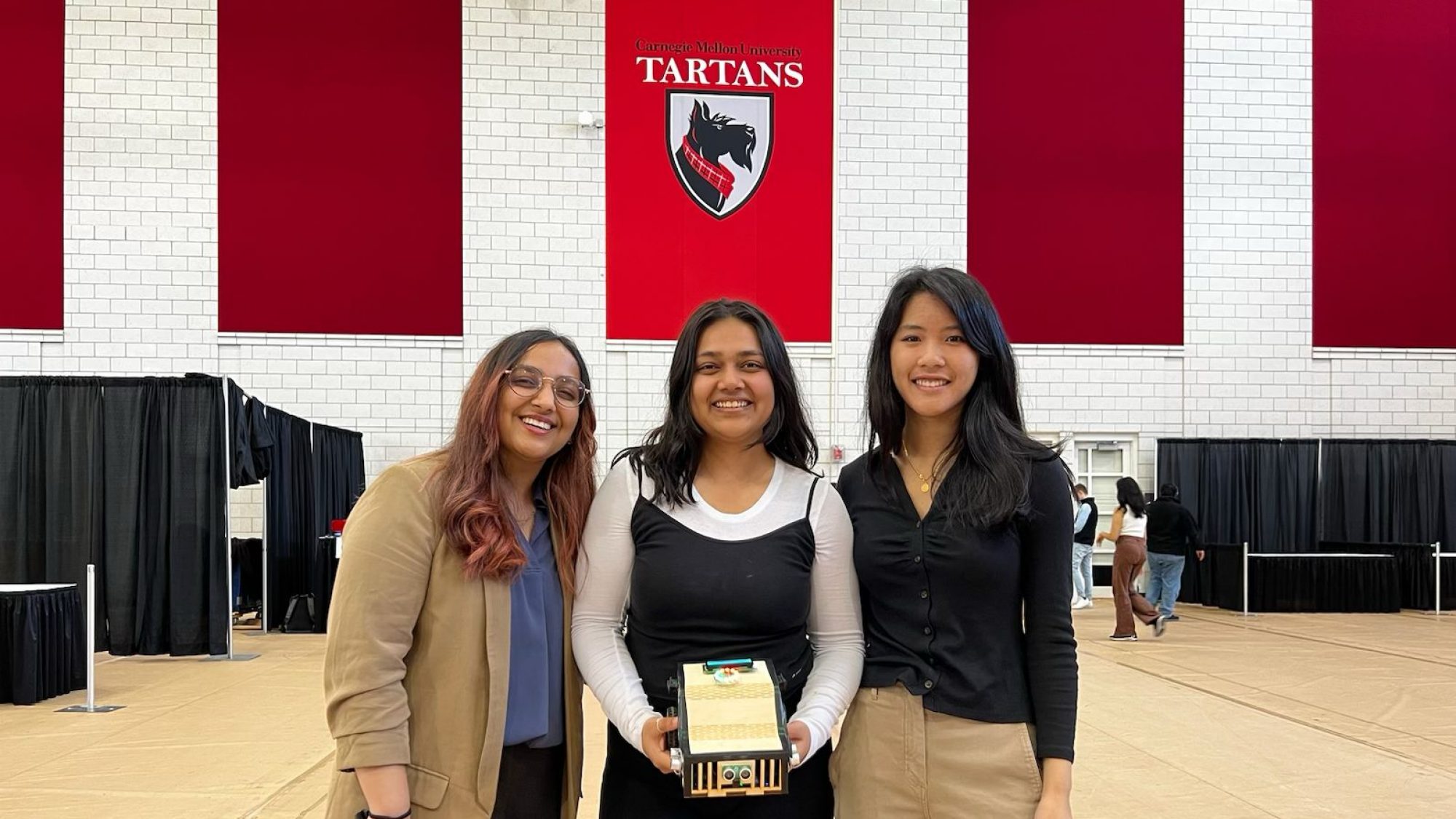

Caroline’s Status Report for 2/18

This week, I primarily worked on the robot design and CAD model. I worked with Aditti to scope out the dimensions of the robot and the layout of the internal components. Then, I modeled the parts in Solidworks and created a layout for laser cutting the pieces. I also inspected the parts that arrived for our robot this week and made additional measurements to ensure that our hardware assembly goes smoothly. We now have most of the key parts needed to assemble our robot, and are just waiting on one of the gas sensors and a shield for the Arduino). We are on track to laser cut the pieces and have the main robot chassis assembled by next week. Next week, I will start testing the parts that arrived. In particular, it is important that we verify that the functionality of the motors and their compatibility with the rest of our systems.

This week, I did not have to apply any skills learned from ECE courses as I was mostly focused on robot construction. I learned CAD modeling from previous internships and the introductory mechanical engineering course.

Caroline’s Weekly Status Report for 2/11

This week, I practiced and delivered the proposal presentation for my team. In addition to the presentation, I helped research and organize different parts for our robot so that we can order components as soon as possible and begin testing and assembly. We had to shift a few items on our schedule such as robot assembly because they required specific parts, but we will catch up as soon as possible. Next week, I will help work on the CAD modeling for the robot chassis and also start setting up the Arduino codebase for path planning.

Team Status Report for 2/11

This week, we delivered our proposal presentation. Based on the feedback we received, we are considering changing the design of the path planning system to rely more on the sensor module to find the scented objects without the assistance of an overhead camera to communicate the locations of objects. The feasibility of this strategy depends heavily on the performance of our sensors, so we will wait until we can test with the actual sensors before fully committing to any design changes.

We currently envision the sensitivity of our sensors to be a concern in the near future. We are planning on mitigating this risk by spending more time calibrating the sensors well and reading up on documentation provided by Seeed and Adafruit. We may also revise our path planning strategy in case the sensitivity of the sensors (in terms of distance) does not meet our requirements.

Because of the proposal presentations this week and the release date of the part ordering form, we have shifted a few items in our schedule to the following week. We plan to start the robot design next week as well as the field construction in addition to the items we already have scheduled.

Our project includes considerations for public safety. We want to ensure that our robot can path plan correctly around potential hazards without running into them or causing spills. Our use case of helping people with anosmia also lends to the positive impact we’re aiming to have on public health and welfare.