For the last week, I worked on getting the motors mounted on the robot and getting the robot to drive a fixed distance in a straight line. Currently, we are interrupting on a hardware interrupt pin and reading from a digital pin for the hall sensor readings for each motor, and using these to update the encoder ticks. Then, the distance travelled by the left and right wheels is computed using the gear ratios and robot geometry in cm, and the robot continues forward till it reaches the target distance without PID position or speed control. From initial testing, we found that our wheels and motors were not secure enough to ensure repeatable motion from the robot, although the traversed arc length was always within 2-4cm of the target distance. We tried to secure the motors better using laser-cut brackets to hold them in place. This helped, but we will still need a better way to secure them in place. For this we will be gluing down the motors/screw them in so that there is no shakiness. Once this is done, we will assess if there is a need to implement PID control or if the robot’s performance is good enough for our purposes. I also helped out with getting the sensors set up for reading and calibration, and spent a considerable amount of time working on the report last week. Next week, I will be focusing on securing the motors, working on the tuning code, and implementing PID control if needed.

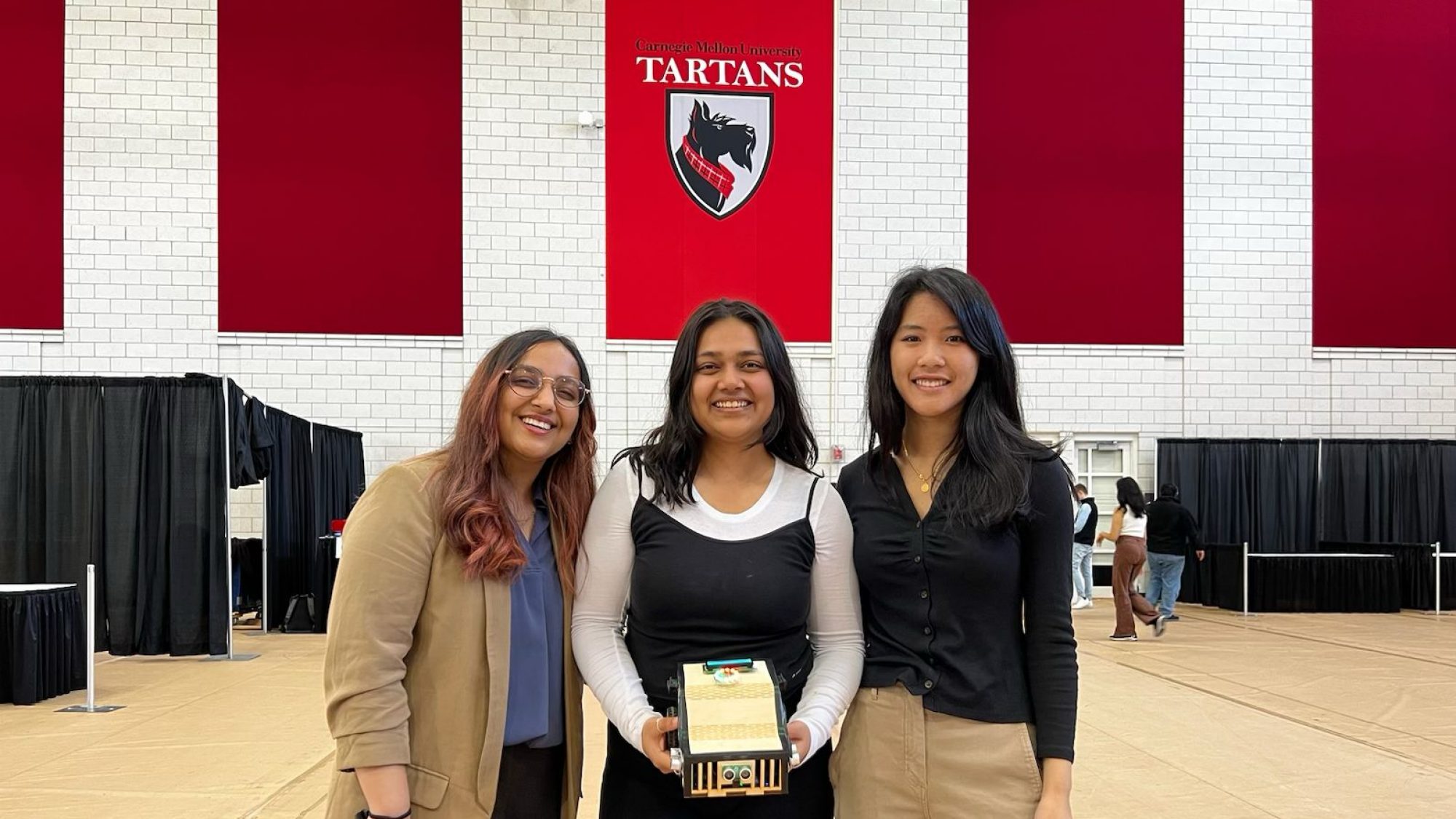

Carnegie Mellon ECE Capstone, Spring 2023: Caroline Pang, Aditti Ramsisaria, Eshita Shrawan