Due to the ethics seminar, we could not do much on Wednesday. We did discuss briefly how our project would potentially cause harm. On one hand, it is a ‘better’ keyboard and keyboards already exist. On the other, Social Media is just a better messaging board. We concluded that by giving some people easier access to services that already exist, we could not cause much harm. We also discussed how a cheaper accessibility keyboard may reduce the job opportunities for stenographers, but there are plenty of other jobs other than typing for the impaired.

We also discussed biases. As a team of able-bodied designers, we need to learn from people with cerebral palsy and what they want in a keyboard/mouse set, and not just what we think they want. We reached out to find people with cerebral palsy and are currently awaiting a response.

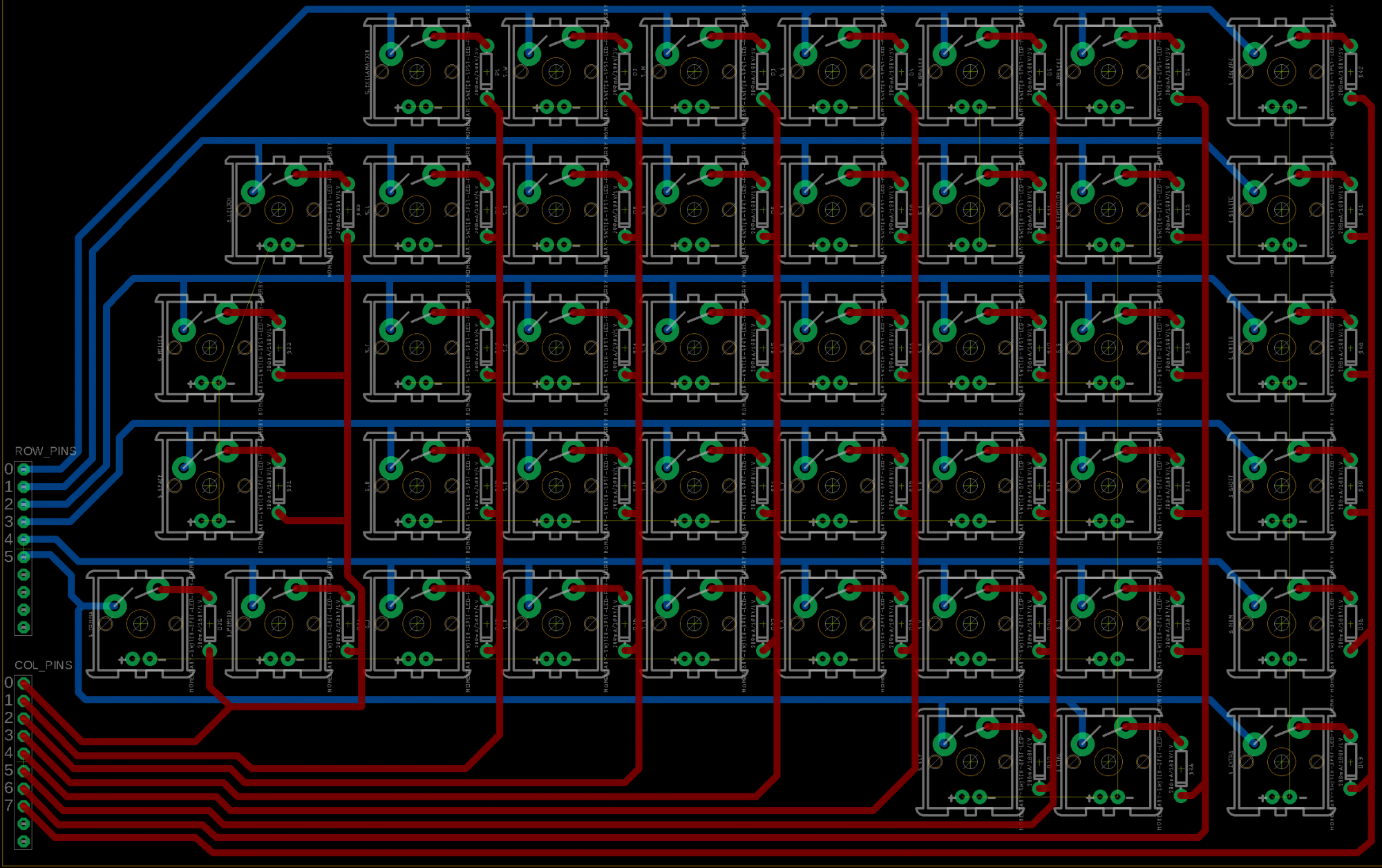

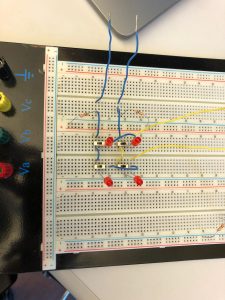

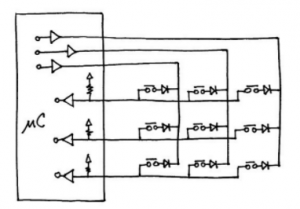

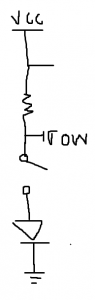

On Monday, we were still awaiting the shipment of diodes. I searched for key switches for keyboards (the things you press). We went with linear key switches, the simplest and most common type of key switch.

This is the link to the keys we plan on purchasing. We chose Gateron Ink Black switches because they are relatively inexpensive and have consistently been rated as having a ‘smooth’ feel. I was concerned about the mention of lubricating the keys, but apparently it does not particularly matter for people who do not already construct mechanical keyboards. I had considered the silent version of the keys, but they are more expensive and seem to require more force to operate.

https://divinikey.com/products/gateron-ink-v2-switches?variant=32067927048257